THX.

It should be even better this time than my 2nd build. Let’s see.

This morning it was time to unpack.

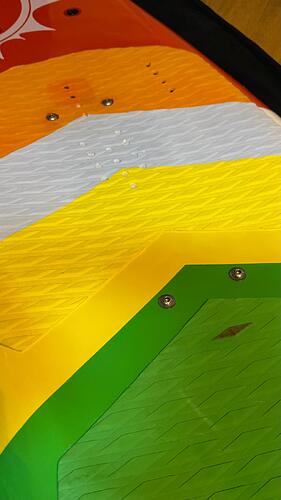

I am more than happy with the result.

A few wrinkles were unavoidable, but since the box will sit in the cutout later, that doesn’t matter.

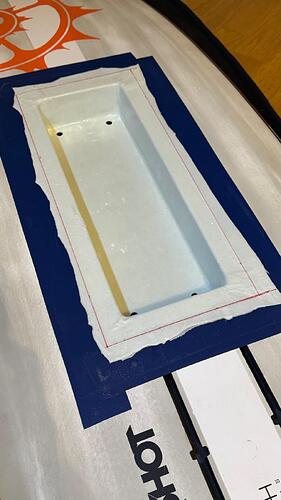

Seal the surface one last time with epoxy.

Next, I will remove the excess laminate and fill and sand it again.

Today I continued with my board.

Drilled holes to attach the Bopla box.

Then I removed the remaining laminate.

Sanded, filled and sanded again for the last time.

Now the paint has to dry and everything will be put together tomorrow.

Why not route the wires from the front? you already had the mast base plate cast?

10S3P for this one? ferry wave catching machine with the smaller axis foils you adapted ![]()

Hello Adam.

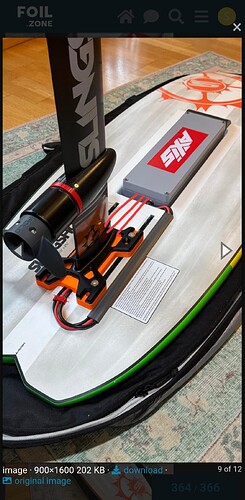

Since my three spacer base plates are all connected to the cables from behind, I initially decided to use the cable duct.

This also gives me the opportunity to use the full area of the tracks.

But maybe at some point I will redesign all my spacers and work with the cables from the front.

Battery setup is 12S3P.

As written above.

I have three masts with different setups.

Since the masts should also work on my second build, I run the cables from the back into the mast base spacer.

This way I can swap all of my setups around.

This could be solved over plugs, maybe with a longer adapter cable .because everything is so clean looking in your build. Isn’t it true that there is no need to water proof the 3 Phase cables? I saw some config with no waterproofing the 3 Phase wires. But I am not quite sure if this is a good idea without waterproofing. Could someone explain exactly?

Hi I am new to this and I have a question for those who use 6384 and ESC150a.

Why do you use 10S3P batteries with 40a or 42a cells that deliver less than 130a discharge.

Should you use 10S4P to deliver more than 150a discharge?

It always depends on the intended use.

For an assist, 10S3P is completely sufficient.

The size of the box is also crucial, of course.

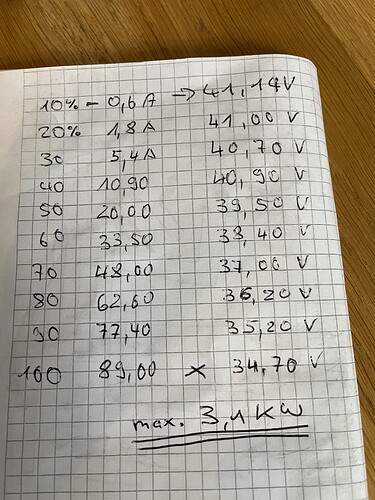

In my test with 10S3P, I got a maximum of 3kW. My favorite is now 12S2P and 12S3P.

10S3P Static Test

Look at the picture from me, there you can see that there is no waterproofing connections.and the guy who build this tell there is no need. I thought, maybe same like a welding machine where you can also touch the metall without problems.

With a welding machine you have high current and low voltage. With 12S it’s a different story. My connectors are waterproof and I wouldn’t use anything else.

Even better, I would also use only waterproof connections. I saw your connections already, they look very good. But I am interested while this guy do not care about that and it seems to work. He even sell this in germany as a diy efoil kit without waterproofing and I do not really understand why this works.

Ok understood. My esc is 150A ( flycolor) I think it can’t be programmed to limit to 100A. With the idea of using 10S3P I have seen that the remote control I can limit the percentage, if I limit it to maximum 80%, I think it would not exceed 100A do you see it right?

Yes, you can reduce the total power with that.

But the 10S3P doesn’t deliver more than 100A anyway.

Of course, it’s more on the phase side.

I also have different throttle setups on the remote.

I suppose you could ask the guy who is selling this for an explanation.

It seems you know that exposing a powered electrical component to water and then potentially getting shocked is NOT a good idea for obvious reasons.

Just because someone posted something that’s kinda dumb doesn’t make it safe or OK.

The guy has answered, because of the low voltage 55V it is no problem and he uses it since 5 years. As you said, I also think it is no clever and clean solution.

So if you knew why the guy said it was OK but you don’t agree that it’s a good idea why post your question in the first place and say that you didn’t know why he was doing this AND clutter up this thread with nonsense?

![]()

![]()

![]()

![]()

![]()

Because I thought maybe there are some electrical engineers who read this and can explain the deep physics behind and the exact voltages possible. also the differencees between direct battery contact and motor contact. But I can understand if you got other targets and knowledge while you are posting here.

By the way, same scenario is happen if your motor gets leaking, this got nothing to do with the guy and his solution. Motorleakage is happening more often then everbody wants and you can’t avoid that for sure. Therefore it is very good to understand exactly what is possible and what to avoid for sure and why.