Hi, I was wondering if there is a problem with the connectivity with the remote controll through the Boplabox - or are you using an external antenna? Thanks and thumbs up for your perfekt build!

At first I thought it wouldn’t work without ext. antenna.

But @tosh.jah told me it should work with fiberglass boards because the aluminum doesn’t shield as much.

So I built it that way to see if it would work with a Maytech V3.

And yes, it works without an external antenna on my boards .

The Bopla box or the aluminum doesn’t cause any problems at all. Carbon is much worse as it shields everything off.

Because my two boards are made of fiberglass, I don’t have any problems with that. I don’t need an external antenna.

It’s more important that there is no water between the Bopla box and the board in the area of the RX antenna.

Especially with my small boards with 28L and 45L, which sink when starting ![]()

The board is actually always under water up to the deck pad, and so my Bopla, which hangs under the board.

I use silicone to seal the gap between Bopla and the board. This allows the antenna signal to go straight into the board and radiate through.

I always leave the area around the Bopla free so that the wind, water cooling can reach the aluminum of the box. This means that my controllers work without a heat sink in the true sense of the word.

This is what it looks like in the case. Antenna positioned precisely and straight.

2.Build

If you integrate the Bopla box into a carbon board, there is a small PG screw connection for the external antenna as an emergency solution.

Or like the FoilDriver do with carbon boards and Gen2: install fiberglass windows in the board.

happy Weekend ![]()

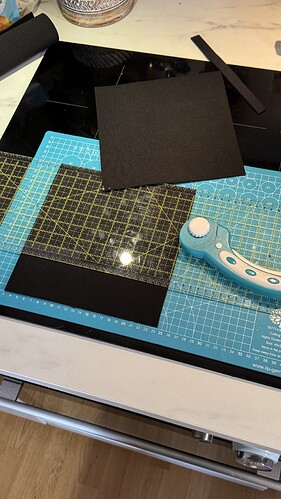

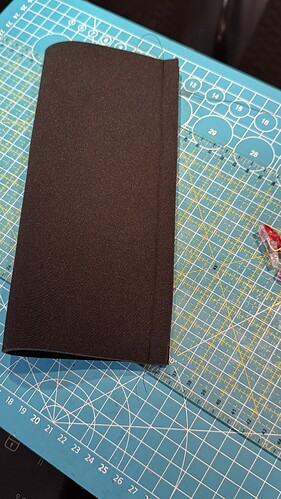

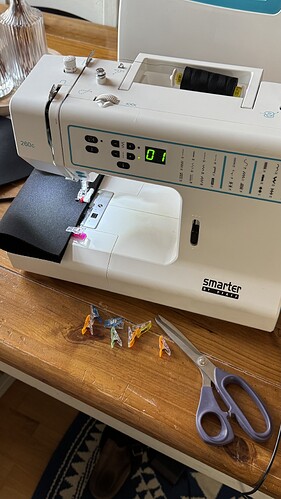

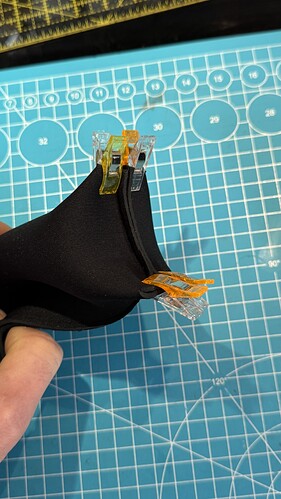

Yesterday I borrowed my sister’s sewing machine again. I sewed protective covers out of 3mm Nepopren for my Propellerking propellers.

@sat_be recommended the neoprene to me to create covers for my RL Foil.

https://a.aliexpress.com/_EGlV50y

For the sewing machine you need a stretch needle and I used UV-resistant polyester as thread.

Great Idea. Very cool ![]()

@hangloose Do you seal the drilled holes in the mast to prevent water getting in? Axis masts have plugs at each end to prevent water getting in the largest cavities.

Also a note to others, Axis mast needs a M4 x 50mm, not 45mm like on slingshot mast.

Yes, I sealed the holes where the cable exits the motor. I didn’t seal the top and bottom.

Hi, is it possible to get the stl file for the 3D printed RXcase? Thanks a lot…

Which one? Please send me a picture!

Hi, your ideas are awsome. I also want to install 2 leashPlugs to my board. Is it possible, you share the 3D file of the 2 little “nubs” to connect the rubberband and the Leashplugs? Would be very kind… where did you find the rubberband- do you have a link? Thanks a lot and greatings from South Germany ![]()

THX. I send you a PM……

Hay Mate

Any chance you could share the files for the connector you use at the top of the Mast plate.

Thanks Love your work and ideas for the builds

Cheers Mark

awesome thank you for that

I would always waterproof a new Ali motor with thermal epoxy.

Otherwise, buy a Flipsky 6384 waterproof and replace the ceramic bearings with stainless ones if you want to avoid the hassle of epoxying.

Just as an alternative perspective. I’ve been using the cheap Aliexpress 6384 without waterproofing very successfully. Stainless bearings and upgrade cables and cut off shaft but basically soak motor in Corrosion X for a couple of days then simply spray after each use. Over 12 months with current motor used in salt water/surf at least 4 times per week. Not a hint of corrosion, not even discolouring of magnets, nothing to indicate any corrosion. I have epoxy encapsulated previously but won’t bother ever again.