I just uploaded the file to Printables!

nice design ! what connectors fit ? can it be used with 8,0mm banana connectors on 10awg ?

Even 8awg is possible. However, only the LMT-6 gold connectors fit, as the connector was designed for this. The LMT-6 can handle up to 400A. That should be sufficient for any application.

damn, only available in germany, shipping cost is crazy ![]() i’m out

i’m out ![]()

The same thing happens to me, 50% short. How do you solve it?

@Mev I use these with no problem, the 6mm version. I doubt they’re as efficient as the LMT6 but I don’t need anywhere near 400a on my tow boogie. Needs some careful attention when installing to make sure they’re square and well coupled as they’re smaller diameter bases. https://a.aliexpress.com/_mLoU2Z5

Hey Markus, awesome builds. I have decided to go a similar route with my build. Maybe you mentioned it already but how have the sealed bearings you are using holding up? Where you do ge them?

Thanks. I’m still using the open bearings at the moment. I have the sealed ones as a spare.

https://www.kugellager-express.de/edelstahl-kugellager-ss-6800-61800-2rs-10x19x5-mm

https://www.kugellager-express.de/edelstahl-kugellager-ss-6900-61900-2rs-10x22x6-mm

Looks like I need to find a U.S. distributor for the bearings, cost too much to ship. I also looked into the Bopla box you used, also too much to ship. I will keep looking.

Hello everyone.

I haven’t posted here in a long time.

The reason was buying an apartment this year, and I didn’t have time for tinkering.

A complete renovation was complicated enough.

But now winter is coming, and I want to replace my Ali 6384 BDUAV with the 6384 Flipsky.

The motors arrived today and make a very good impression.

One motor will go on the assist mast and the other on the eFoil mast.

Some of you might be wondering why the change. Better quality than the Ali DIY setup, and I think better performance.

My next step will be to replace the ceramic bearings.

Hey, welcome back!

My first bduav 120kv is going strong, after many sessions, on 4 different pods/mounts, dangling from the phase wires a few times, being quite rusted ang going on the third set of bearings ![]()

My main complaint is the ridiculous thin phase wires.

Why did you choose ceramic bearings?

The Flipsky motors are heavier and less efficient than the buad. However, the waterproofing is pretty good and therefore requires much less maintenance.

When ordering from Flipsky, you can’t choose the bearings.

The motors always come with ceramic bearings. However, I know from my experience with my Saite 63100 that the ceramic bearings only lasted an hour.

That’s why I’m switching directly to stainless steel.

Sorry I misread!

Food for though

6900 bearing max dynamic load = 1270 N

1270*0.25 = 317N of axial force before the bearing fails.

317 newtons is not a lot of kg, most foil setups seem to provide between 30 and 50 kg of force.

The 6384 have two front bearing taking the axial load, but two is barely better than one in this case.

From what I could find, ceramic and stainless are supposed to have similar load ratings, but probably handle axial shocks and overload differently. I wonder what part of failures can be attributed to the disassemble / reassemble shock due to magnetic pull when it snaps back together.

On my Flipsky 6384 I replaced one of the smaller bearings to stainless and left the others in stock ceramic.

I think this is also what Foil drive is doing at the moment.

This so far worked for about 600km.

Only small issue is the stainless bearing getting a bit rusty from seawater.

Great idea. That’s how I’ll do it.

stick a little corrosionx on this bearing and it should be good

DIY weekend.

Today I removed the rotor.

What can I say: I’m extremely pleased with the sealant.

Trinity V1 is still installed.

More tomorrow.

Today was CAD day and dismantling of the old motors.

The masts are prepared for the new Flipsky motors.

The included gold connectors are only for testing.

I would never run 100A through them ![]()

I have my LMT-6 for that.

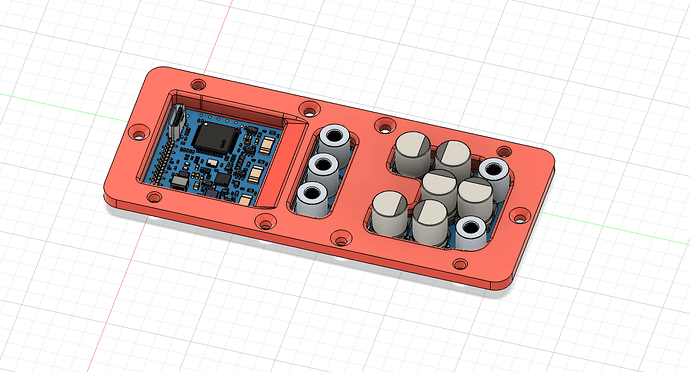

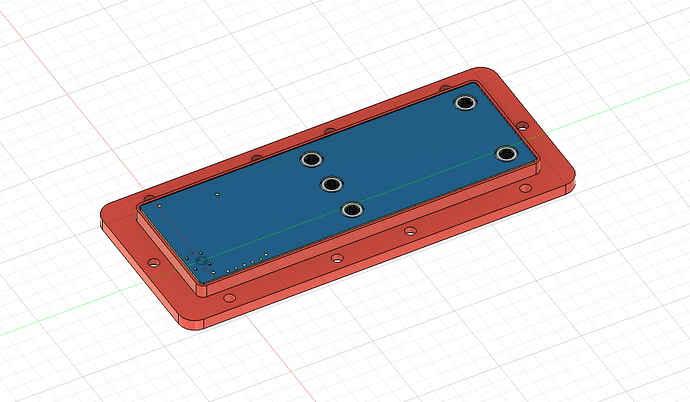

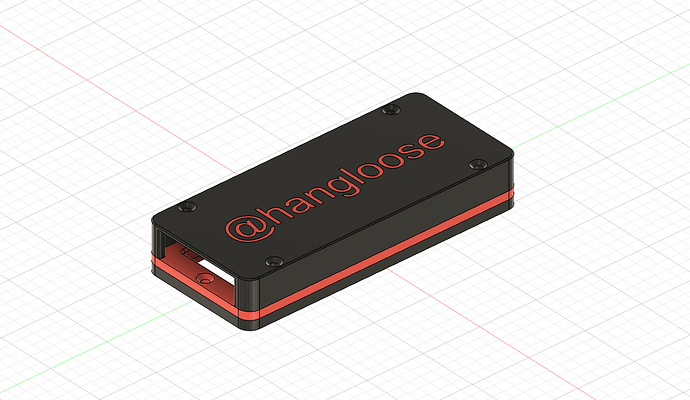

My Bopla Box is also getting an upgrade.

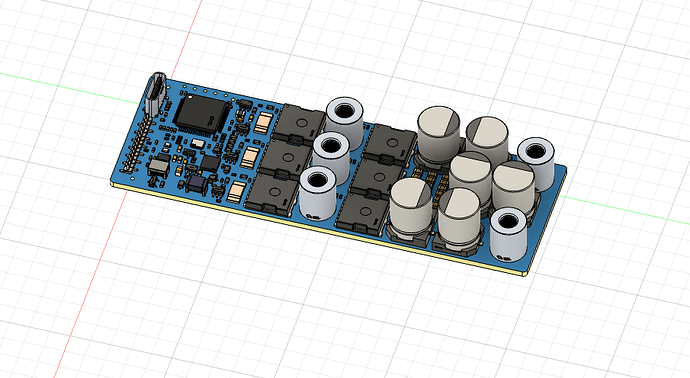

I’ve decided on a Harry M ESC. I’d like to delve deeper into VESC,

which is why I’m switching from Kontronik to Harry.

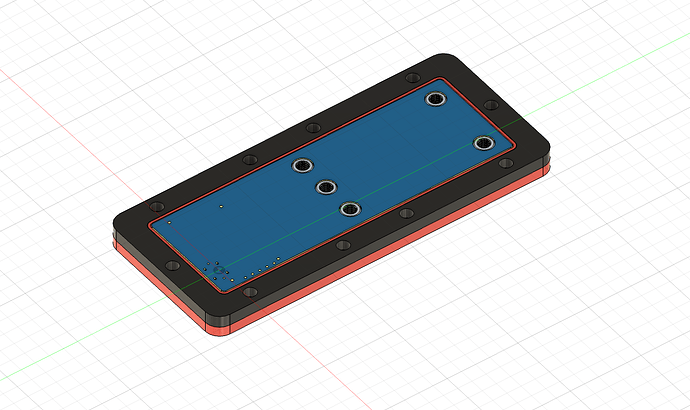

A new VESC case was also created today using CAD.

Now it’s time to print everything and see if it fits ![]()