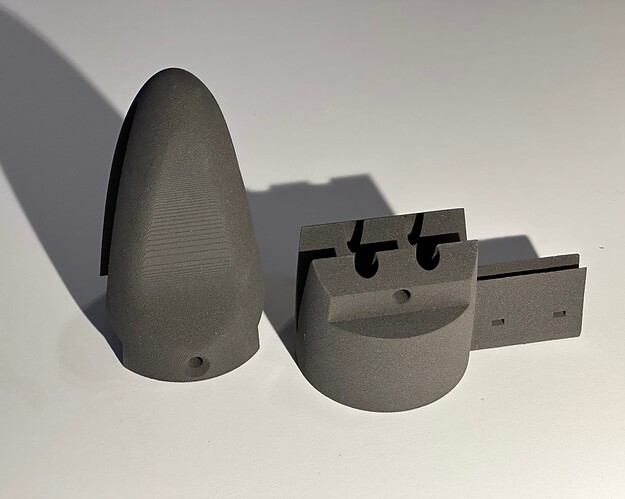

@hangloose Thanks for your awesome motor pod design. Prusa at home in PETG and via Craftcloud SLS in PA12:

Realy nice. Thank you

It has become cold in Germany.

All the more time to design and craft. ![]()

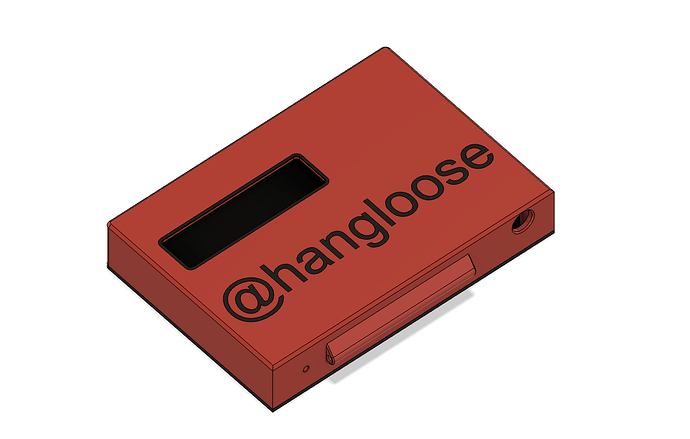

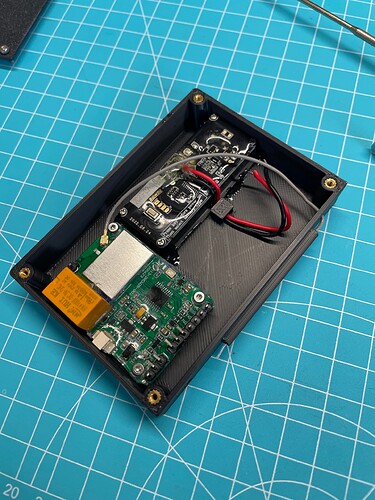

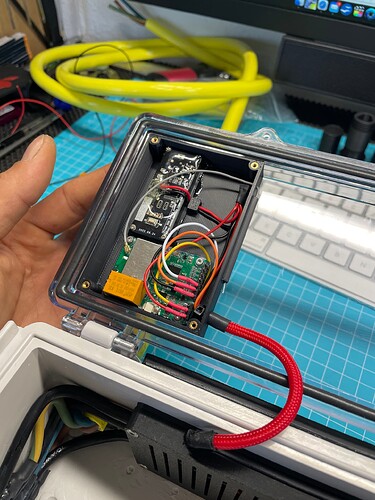

My RX & Display Panel got the V4.

I have already added the V4 STL to my printable account. Also a clean version ![]()

https://www.printables.com/de/model/644037-rx-display-panel-for-foil-assist-box

The box passed the first test run in the bathtub, including the rotating motor.

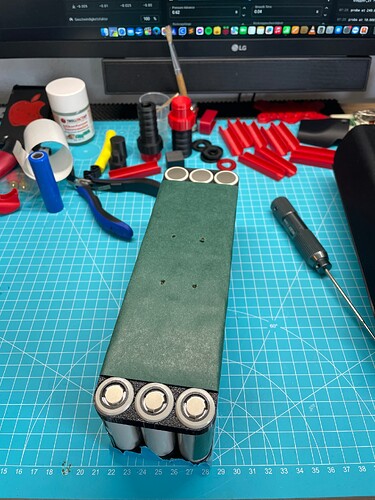

I also potted my replacement motor with 50gr thermal epoxy.

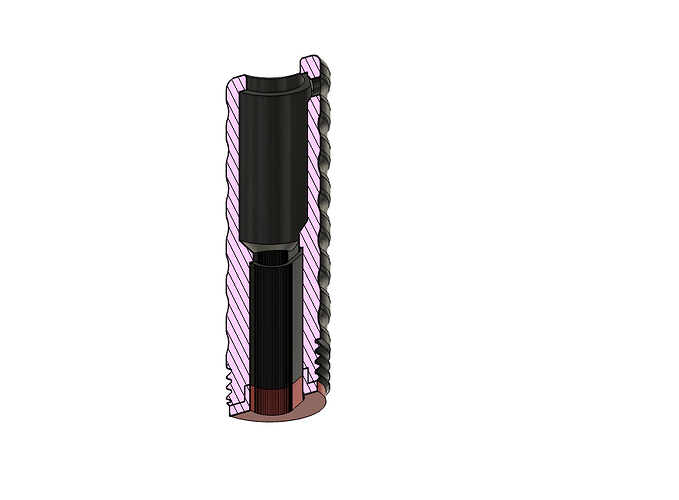

Next week I will be designing my own waterproof MT-60 connector.

The first prototypes have already been made.

This build is so good. You are very talented and settle for nothing less than perfection  . Well done.

. Well done.

Thank you very much

I don’t stop!

Just a heads-up: If you’re not using a good thermal potting then motor is likely to overheat…

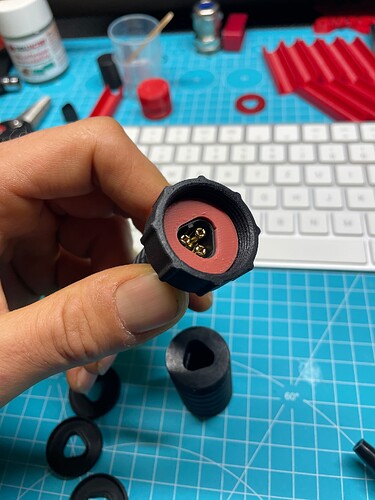

My waterproof MT-60 connector works perfectly.

Everything is tight and no water comes out.

There is water in the balloon and after two days nothing has come through.

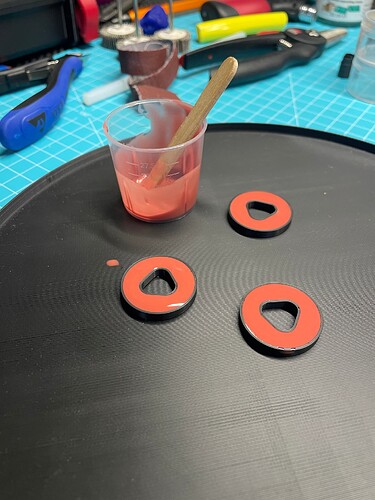

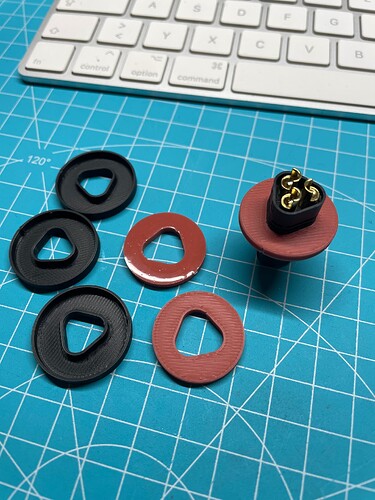

I printed the prototypes in PLA and the seal in TPU.

The first final version made from ASA-CF.

Now the connection is optimized a little and reduced in size!

The last few days I’ve been working on my waterproof connector.

With ASA-CF it just looks awesome.

Then unpacked the engine.

I am HAPPY ![]()

Markus, can you share the STL files of the tools you made to disassemble and epoxy filling the motor ?

Thanks in advance.

Everything looks so good. I hope you share the stl files for those mt-60 waterproof connectors. Id love to upgrade my tow boogies with those connectors.

@iasen_vak:

I just published the Rotor Puller STL. You can find the rotor puller here:

https://www.printables.com/de/model/648779-6384-motor-rotor-puller

Unfortunately the puller for the steel shaft doesn’t work. The pressure part is broken because the shaft is seated too tightly in the rotor. Simply mount the rotor underneath and drive out the shaft with a hammer blow!

I can also upload the 3D printing sleeves for casting the engine.

However, I would only do it with foil like I did with my second engine.

It’s much easier and cleaner.

@Jesserosco:

Thank you.

I will finalize the waterproof connector at the weekend and then publish it on my printables.

@hangloose Thanks for the reply.

I will try to make the motor waterproof with simple methods.

MTW-60 Waterproof Connector now online.

Assembly instructions at Printables!

https://www.printables.com/de/model/649814-mt-60-waterproof-connector-mtw-60

The balloon with water test attaching it to the opening. Having difficulty to grasp how it tests waterproofing. Please elaborate.

For the water test, I created special pressure parts to check the tightness. I tested with water in the balloon, with air in the balloon and the pressure part under water.

Right, so you are testing the same printed config+material on a different dedicated for testing part.

Probably you used a setup for waterproofing - like higher temperature, thicker lines, higher temperature?

ASA CF 255°C / 0.1mm and 5 walls / Enclosure 47°C

TPU can be used as a seal for my MTW-60 connector.

But with silicone rubber everything makes an even better impression.

Shore of the Silicon A33!