Hi Guys, anyone has already been testing the new Maytech MTI 65162 Motor? What about their prop, did somebody try it. Does somebody has a 3D file for the duct already? THX!

Their prop sucks. There are many files floating around for props and ducts. Search is your friend.

Can you be more specific about “their prop s…” Di you try it yourself? What should get changed?

Many people tried it. It is a decent prop and probably the 10usd most cost effective once cut down to 132mm.

@jeffM could fly with 18A and a Gong XL curve wing from 11 to 25 kmph.

There are more efficient propellers like the Flyiing Rodeo one and more expensive too (120-140usd ?). There’ an ongoing group-buy.

I did not try it, but if you read more and do some searching you will find the details about this prop to be common knowledge on this board.

In unmodified form it is too big. It is also possible to order it with a version of the motor shaft that requires modification to make them work together. Far from turnkey as advertised.

If you have a lathe and/or a milling machine, then perhaps it is no big deal. Most don’t have a full machine shop at their disposal.

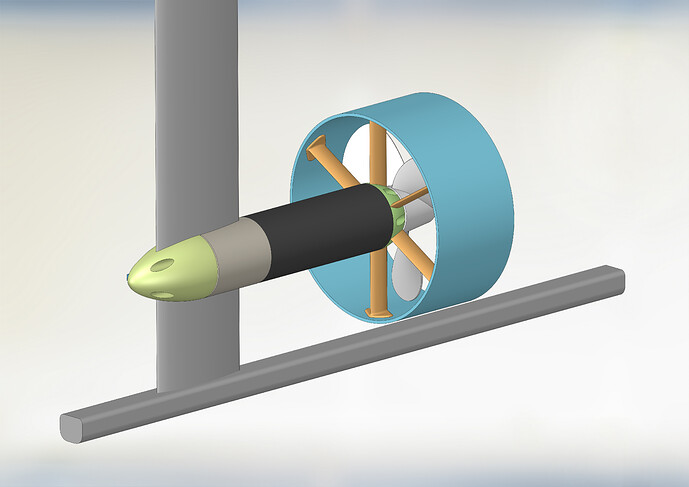

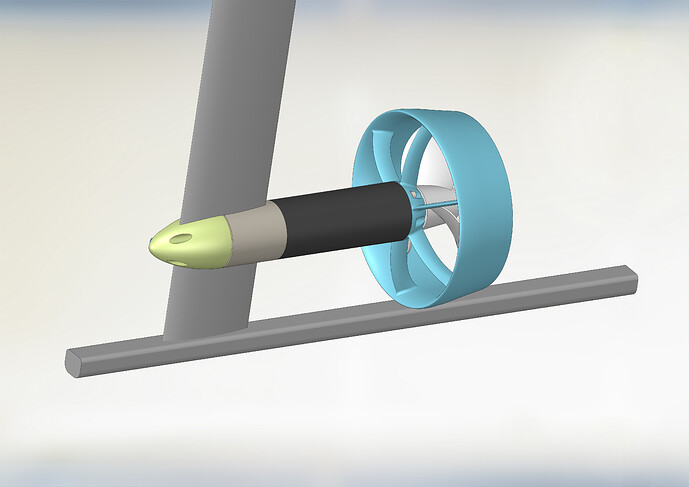

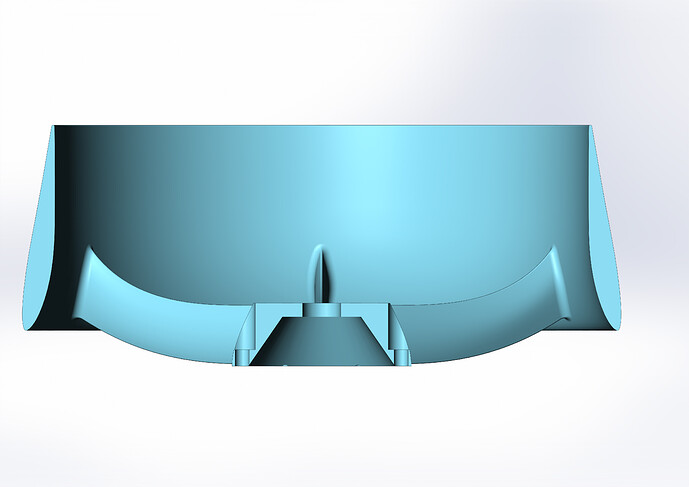

My duct design is in progress. I will print by parts because i have a resin printer for little pieces and for duct I will use Carbon fiber or Composite using a 200mm PVC joint as a mould maybe.

https://www.dropbox.com/sh/m6j1zpcjgt3uvcz/AAC5qsP-hKSEGgJ2SIiMBZlMa?dl=0

And this a Version2

Looking good f16model!

Is this for the MTSP0504 (7.25x5") or the MTSP7507 (7.5x7") Maytech prop?

Also. Do you mind sharing the .stl file so we can 3D print this?

Thanks looks good. Can’t wait to print it out?

Thanks @Kian. Link was updated with STL files.

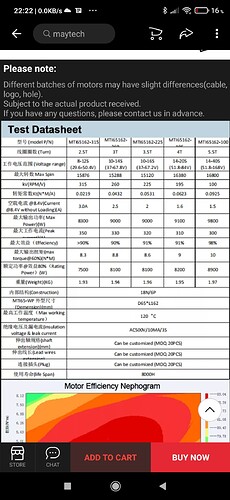

I have 7.5x7" BA prop and Maytech MTI65162-SF 120KV motor

Thank you.

I have the smaller prop (7.25x5") so unfortunately your duct will be to big for me.

What clearance do you need between prop and duct? Will you print a complete duct or by parts? My design is by parts because I have a resin printer for little pieces.

I have two of the same motors with the 12mm smooth shaft. I will print the complete duct. Can your file be modified in fusion 360 to print complete? I plan on using the Flying Rodeo propeller which I believe has a 6 inch diameter. Can the duct diameter be adjusted for this diameter? I haven’t found a duct that fits this motor yet. I modified a file for the flipsky 65161 motor but still had to use a die grinder to get it to work. My cad skills are limited  See photos.

See photos.

I changed diameter of duct to 6", check before printing. I dont use Fusion, I use Solidworks.

https://www.dropbox.com/sh/hdjk7rtccaw8cp3/AAAxVrBggGm0baiAiEk9kUt1a?dl=0

I like your version 2 model. Thanks for the 6 inch duct size, Your the man! ![]()

![]()

You may want a smaller duct in the future as well. I have read a few posts and many people are using your prop but they have reduced the diameter of the prop by cutting the blades down. I understand that the larger prop size takes more power consumption to use, which equates to less efficiency and lower overall ride times.

example of the reduced size prop:

Do you mind making one for the MTSP0504 (7.25x5") prop?

Motor is same as you have, but the 100KV version.

And yes. I know the 7.25x5" prop is no go, but it is all we have now.

I Update Dropbox folder “Others”. Check before printing! Please let me know if it works for you and share picture of your reults.

Thank you so much. We will start printing it tomorrow and let you know the end result!

Error. We thought that we had the new 65162 motor, but we still have the older 65161 version.

Unfortunately does the duct not fit on it (screw holes do not line up)

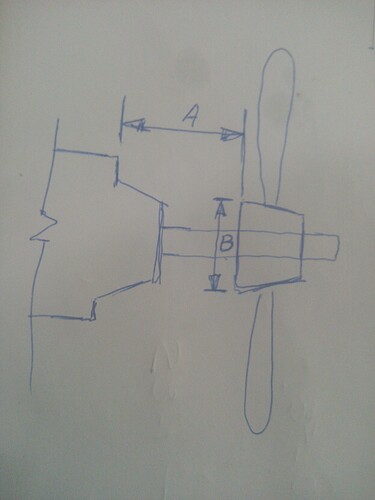

Also need these dimensions for your installed propeller. And send me drawings or 3d model of your motor