Here’s a picture. I keep my FSESC in a plastic compartment because my board leaks and I want to keep the electronics dry. Obviously, if you have something to enclose the BT/radio module in you could dispense with the container. For the actual cooling, It’s just a little bit of plastic tubing and a small 5V pump that I run with a 9V battery. This circulates the coolant through the FSESC and then air cools it in the tube. So far I have run it continuous for 40 minutes with zero problems.

Sorry, I didn’t realize how bad a picture that was until just now. I’ll get another tomorrow and repost.

Absurdly simply solution. $10 for the pump. $5 for the tubing. I use coolant because of the temps at night here.

In this picture you can see the small tube coming out of the exit and right back into the ESC. The larger ones go outside the box where the pump resides.

The pump is a simple 5V pump with an on/off switch that I wired in. A 9V battery lasts for maybe 5 to 6 hours.

Hi,

thanks for sharing. The benefit for sure is that there is no chance that some residues get stuck in your tube system. But still you need to run tubes in first place (also going out of box) and you have a pump. My target would be to avoid any of those. For example with a alumina plate mounted on bottom of the board. This works for different esc already, however I do not know if this is also valid for esc with water cooling enclosure.

thanks for the link JP

Hi Jeff,

First I’d like to thank you for all the information you share and congrats on your different builds.

I have a question, can you tell me how you printed the mast clamp? Type of material (ABS, PLA, PETG…) and infill (100% or much less and later filled with epoxy)? I wonder if it will be strong enough if I print it in ABS with 100% infill.

If others used other solutions I’d ba happy to hear them.

Thanks and greetings from a French living in California.

Hi ,

I printed the mast clamp with PLA/CARBON 100% and added an epoxy coating

Hello, why did you take lithium batteries instead of lipo batteries?

Pourquoi avoir changé de type de batteries entre la version 2 et 3 ?

Hello the board thickness is 10cm and the height battery box is 9,9 cm. I don’t understand, can you explain ?

(Sorry for my english)

Hi Coupli,

I changed for 18650 for the safty.

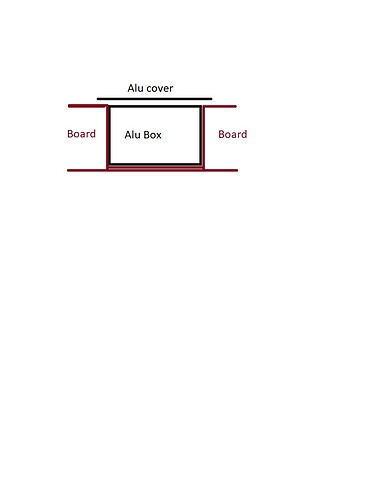

for the thickness the alu box is directly glue with epoxy with the bottom layer and the upper

like this

02/03/2021 Prop and gong wing test

I didn’t finish my V4 Efoil, So I tested the new props and Wings with My V3.

First test : old wing configuration (curve XL) and new prop Flite

1 amp less than my alu prop and no more noise  very happy

very happy

so 16A with this configuration

Second test : same wing, new alu melted prop

unfortunately 20A

3 test : prop flite, wing gong veloce XXL stab 47cm veloce

consumption 14A

and final test : prop flite, wing gong Veloce XL, stab 47CM veloce

consumption 17A/ 18A, but I increase the speed, and stability is better than XXL veloce

So for my mew V4 Efoil I 'll used the Veloce VS curve and the prop Flite with the cone is my better prop until now.

I’ll began a new thread for the construction of my V4 soon

And the contact between carbon and aluminum is not a problem ?

What speed you get at 18A with Veloce xl.

Thanks

And what is thickness of alu cover ?

Hello JeffM.

Nice job!! How do you power on your board ? By plugging your magnetic switch? Do you have an extra switch like an antispark one ?

Hello

what do you use as a pump for cooling, thanks

See upper on the parts list, you have the link on aliexpress

max36

=> yes I plug the magnetic switch to power on, I have only an connector XT90S

like that

You can see upper, you have the schematics

Coupli

=> thickness of alu cover = 2mm

and no pb with alu and carbone, but I use it only on a lake

toto44

=> at 18A with veloce XL 22-24km/H