Thanks and yes these are the same values I have more or less. So many other parameters in that VESC tool though I guess there is no shortcut and I have to dig into understanding all these parameters.

Foiling is not an issue been riding with foil on many supports for many years now. Been riding lift efoils also those are great if it was not for the price tag  and well of course it is more fun to ride diy boards (when it works…)

and well of course it is more fun to ride diy boards (when it works…)

Propeller is surely an issue as you stated. See if I can get my hand on a new one before the lake freezes. Maybe I’ll dig the forum and see if I can print one that is known to work well.

Thank you larsb anyway for having taken the time to answer.

If someone else out there is on the same motor and is willing to share his settings

Where are you located? I’d get a propellerking prop if i was in the EU or a Manta prop if you’re in US. The 3d printed ones work but they aren’t as robust and the prop is as important as the rest of your system.

Apart from that, if you’re getting those power and current numbers you really have enough to lift, either motor control is really inefficient or the drag of your setup is large and/or propeller not good.

I can get cutouts at max throttle just like you but i didn’t try to tune motor parameters, just ran the identification and it lifts down to 900cm2 wings @ 130kg

I’m in Sweden and yes i was looking at the propellerking the thing is the shaft of the motor is 12mm with groove and they don’t seem to offer that kind of option. I’ve downloaded a print file for a a propeller that is known apparently to work at least I can quickly rule out quickly this parameter out of the equation. will get a more robust one later. drag may be the problem but i don’t see why there would be more drag from having the motor under the fuselage. Maybe the drag comes from the propeller. but the thing that I didn’t log more than 4000 w at full throttle when I can read others can peak at 7kw hints that there is clearly a motor control issue. Since you suggested not to pay attention to the chinese specs on their website do you think it is an issue to run the motor at 14s when the specs of the motor shows 12s max?

If the propeller is too big, you don‘t get max power because you need rpm to get to max power. If you have a splined shaft you might try this prop, the original is very good:

Thanks for the file but the link is dead

No, definitely not a problem. These motors are being used at 14s regularly. What will happen is that eddy current losses will increase with higher rpm , lowering efficiency slightly, increasing heating - but you’d need more rpm than 14s x 120 kV for it to become an issue.

(you’d also need a small prop combined with full throttle for longer periods to actually run motor like this and this basically never happens.)

ok so if I understand correctly the only benefit I could hope from running 14s instead of 12s is a bit more autonomy and a bit more top speed provided the propeller allows it. on the other hand with 12s the rig is 3kg lighter. It doesn’t seem really worth going 14s. Do you see any good reason why I should run it 14s instead of 12?

If you are OK with the speed at 12s then the main difference is the 17% increase in energy and runtime with 14s

The diy mast adds drag and the prop is not good, these two will cause added losses. Do you have a normal mast inside the cover? If so, then the increased wetted area will mean it’s harder to get up, i don’t think it’s the main issue though.

What does it behave like when you start? Can you see cavitation on the prop?

I printed the flite prop (thanks sat_be for the file) and it is now curing the second coat of epoxy. In the meantime I’ve been tweaking the motor settings and it ramps up nearly perfect on FOC mode. Just out of the water and as it now can reach higher rpm it is obvious prop is cavitating preventing me to reach takeoff speed. Been pumping like a maniac to help but with inflatable board and extra layer of battery soft pad too much loss of energy. No success. I could feel indeed today all that extra drag created by the mast mount.

Tomorrow I’ll try the new prop hopefully this will solve the problem.

Do you have a link to the prop?

Just tried the printed flite prop. Feels lot better. No cavitating however and unfortunately I’m still left with my motor control problem. I thought I had tweaked the settings the good way but now that the propeller is more efficient and with more torque on the prop I get cutoff again at around the same 3000w. So f…ing much frustrating. How do you guys make your bench test at home to simulate load before heading to the water? Even if the lake is not that far it is not ideal having the computer at the beach and open the controller everytime you want to adjust something. VESC tool over Bluetooth doesn’t have all the desktop features.

I have a barrel filled with water for the tweaking, bathtub should also do if you’ve got one😄

Indeed I have one IBC container laying around in the garden but how good does it simulates a steady water flow when everything is bubbling around… not sure. Anyway I’m at the point where I think the toilet bowl would be the most suitable place for that piece of crap of electronics right now:exploding_head:. Hopefully there will be a good windy session soon that doesn’t require any computer to have some fun. Well until I start complaining about unstable the wind is I suppose

You’ll see if the controller can drive full current and tweak settings if it can’t so it definitely could be helpful.

You might also get some help if you post the identified motor parameters here so people can help to verify if they’re good.

Hello again. I did run some test dry and I’m not able to get consistent motor detection anymore.

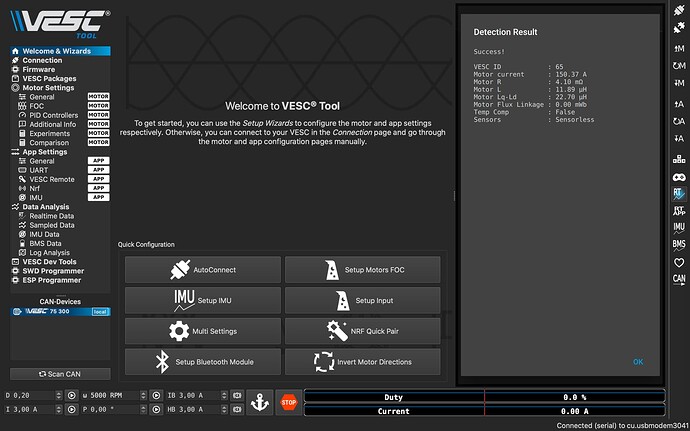

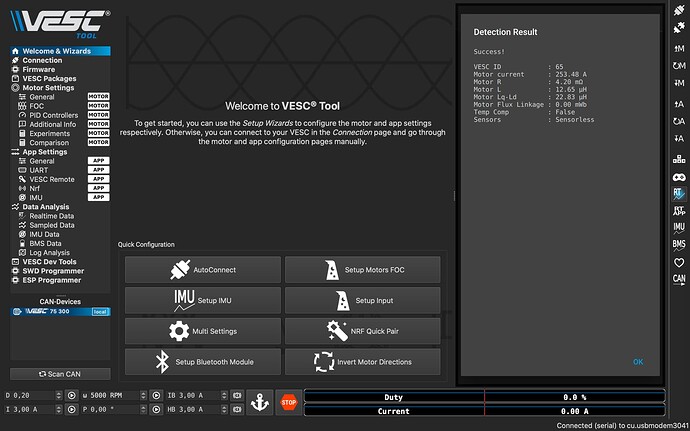

Below the first detection using medium inrunner and then the 2 other ones using large inrunner. this is on fw 6.02 and phase filter off.

I have the feeling that something is dying somewhere slowly. Motor is making more and more weird sounds and I’m not able to run it without cogging no matter if I re load the profile i used on the previous days that was at least spinning the motor. I tried several other firmware withtout any succesful results. Cannot measure flux linkage anymore either and several time the motor detection would fail because of not being able to measure this flux linkage on FW 5.02

Can it be some loose wire inside the motor causing the pb? or do I simply got a bad unit? did I manage to kill the motor or controller? is it worth opening the motor or is it best to chuck everything in the bin and get myself a combo motor/controller that is known to be reliable. in which case which supplier would you recommend?

Something is wrong, that’s obvious but it isn’t the esc motor combo in general, i have the same and it works well.

Could be something like a faulty esc, short circuit in motor or a poor connection somewhere in the system. Are the motor phase connections soldered properly or is it still a test setup? Are there any signs of cable damage along the motor phases?

short circuit inside motor: does the motor cog badly when not connected to esc with more resistance at higher speed? (it cogs quite a lot normally)

Is there more resistance turning the motor while esc is connected and not on than when motor is disconnected from esc? (mosfet control is then not ok, esc is busted)

Motor flux linkage is always zero in the pics, this can’t be correct. I wonder if someone has seen it before, SW might be screwed up?

Do you have the original settings and firmware to revert to? google flux linkage error and VESC and you’ll find some threads on the eskate and vesc sites

Indeed been going through all the threads I could find about the flux linkage problem and the fix relative to FW 6.02. It doesn’t help. I tested the motor disconnected from the esc and I get in between each phase a minimum resistance that is identical to all combinations. Resistance test with ground shows open circuit. I think there is nothing wrong with the motor and that I certainly fried the ESC when I ran some test at the beach using the BT app. I think I did a motor detection at some point and reset all parameters hence turning phase filtering back on. I tried downgrading the firmware using the archive tool and no luck either. Not being able to get a steady repeat of the datas using same settings and same conditions from one try to the other really hints towards a hardware problem. I cannot manage anymore to get the motor spinning at detection with the same values as before that try on the beach. At detection it is noisier than usual and instead of spinning fwd or reverse in a continuous motion it keeps alternate fwd reverse rapidly and makes terrible sound. Foc_openloop 50 1000 can’t get it to spin either. Well I think I’m good to buy another ESC. Always good anyway to have spare. The only positive side is that I’m getting more familiar with VESC tool now  and the zillions options to choose from start to make sense. Any ESC one would suggest that is really good quality and that would run the 65162 the best?

and the zillions options to choose from start to make sense. Any ESC one would suggest that is really good quality and that would run the 65162 the best?