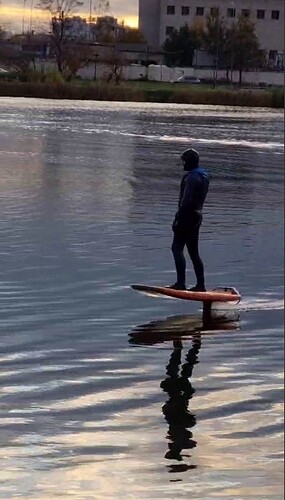

Here are some photos of the @Strongarm Armstrong design on a Axis ALU mast. I’m currently printing a mod of that design to better fit axis so will post if I have sucess.

I will pray for your success. If you fail, here is a link to a file already adapted for Axis.

Same for me

Pod only for gong mast (carbon)

The other stl is too complicated to print with lot of losses

Thanks

Well. Toto44 said he can do it, not that he will do it, so I guess all of us 3D CAD noobs have to wait until something that fits pops up. In general I dont see the point in integrating a cable guide into the pod, as there are different requirements for its size and shape, and does look a bit draggy too. Strength wise it is also better to have a closed loop around the tail of the pod. KISS

@Strongarm @JFoiler I looked at the file but would be good to know for sure. Did you use a 4mm dowel/shear pin for the Pivot rod with a bit of glue? And the strap screw holes are 3mm, so did you use M3 or M4 caphead screws for that (M4 maybe to get a tighter hold)?

FLYCOLOR X-CROSS HV3 160A, without modifications or additional settings. Odrive 6374 (Saite), Axis PNG 1150. Air temperature 2 degrees Celsius. Two continuous sessions of 25 minutes each with battery (8s3p) replacement. My summary - this is an excellent controller, without overheating, without a melted box and unsoldered phase wires (Flycolor 80A). Many thanks to the person who recommended it.

Hello

Great! Same motor but 6384 and 8s3p. But…

With a propeller that you have bought where ? Stl or?

Thanks!

If this question was directed at me, then this is a printed folding version of the Volker propeller.

Just tried an M4 cap head screw in the pin hole of the Grunt Versa strap which I mounted in my strap pod after grinding the buckle end. Screwing cap heads in looks like a great solution, shame I hadn’t thought of it because these screws are easy to get hold of and would likely screw in and hold (using 4 x M4 x 30mm cap head screws for 6384 motor mount which I don’t have yet). M4 rod didn’t fit in pin holes, so reamed out to 4mm and have ordered SS 4mm dowel pins for hinge 40mm (which I’ll grind to pod angle) and strap pins 30mm & 20mm. I’ll need to glue these pins in with epoxy. My Versa strap holes are 5mm and the cap head is ~ 6mm. Have yet to put it all together and find if it works however!

I don’t ride with 3D printed motor pods. Mine are all cnc’d. Also not riding gong masts. Which mast are you using?

here is the strap pod for Gong HM Mast (the 85cm one) without cable guide

Gong HM 85 cm Mast strap pod for 63mm outrunner by toto45 - Thingiverse

Hi rttn,

When you say 25 minutes session, do you mean efoiling all this time or just for motorized lift and then pumping ? For information I am thinking to build a low cost efoil based on 6384 to ride ~1hour at 20-25 km/h. So it would mean I need 2 of your 8s3p batteries in parralele. Also I checked in your previous post, and you used to have a 150A Fly color. Do you think I could take the cheaper 80A flycolor or the 150A (I think they only sell 80/120 or 160 A now). Thank you for your help.

25 minutes are distributed as follows: approximately 60 percent in efoil mode, the rest of the time pumping.

My old Flycolor 150A is only rated for 6S and I don’t think it’s a good choice right now. I wouldn’t go for the cheaper controller options unless you want to deal with overheating all the time.

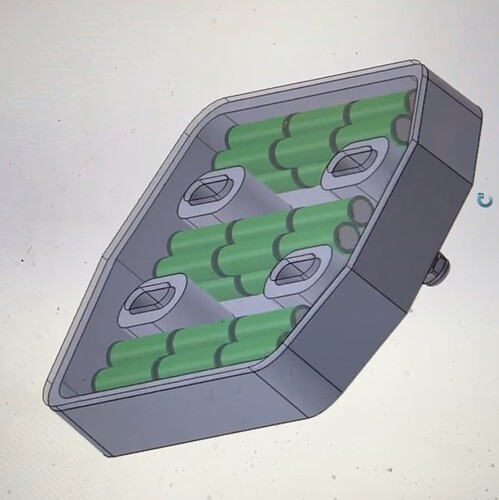

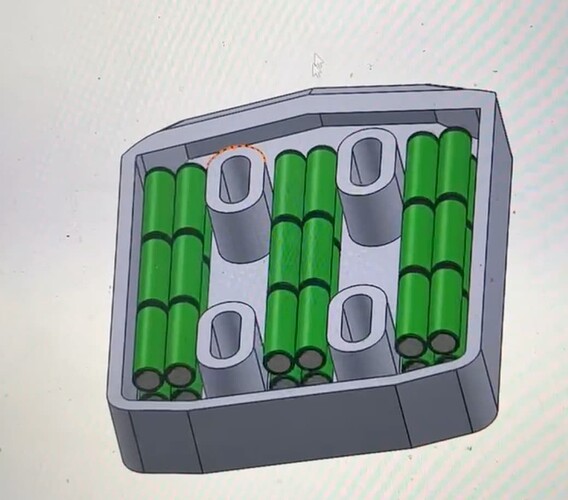

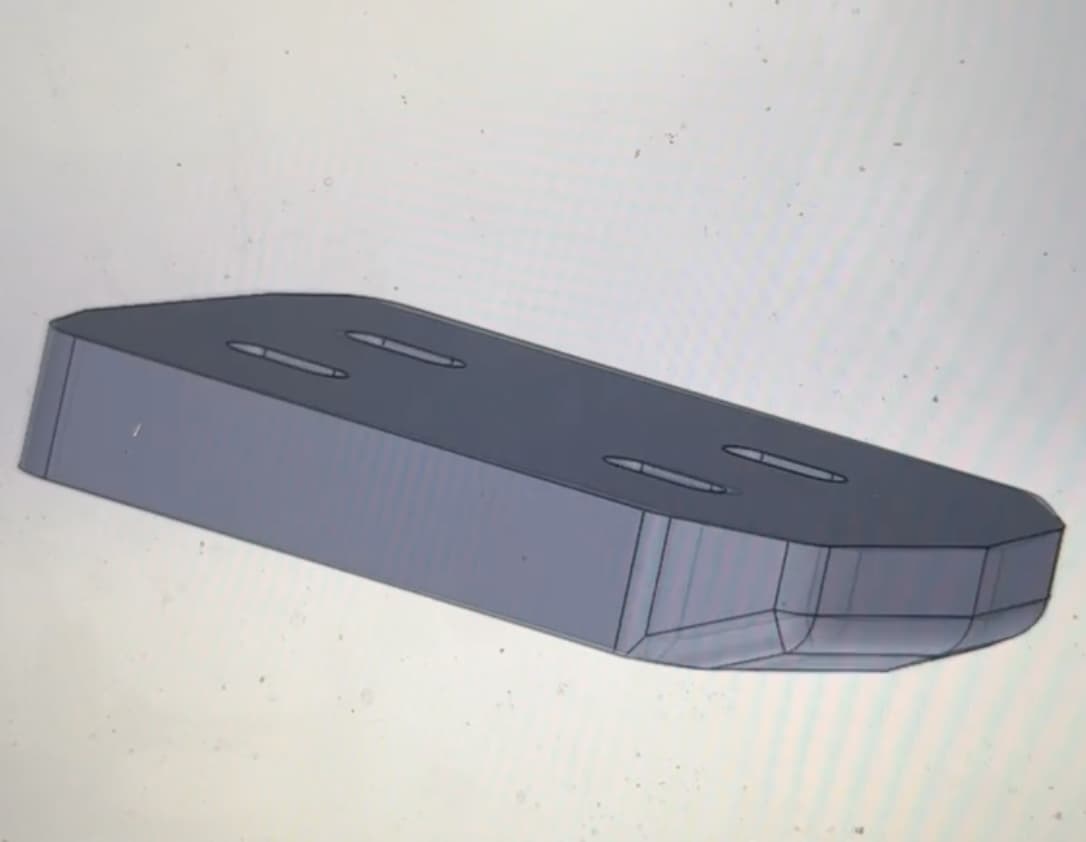

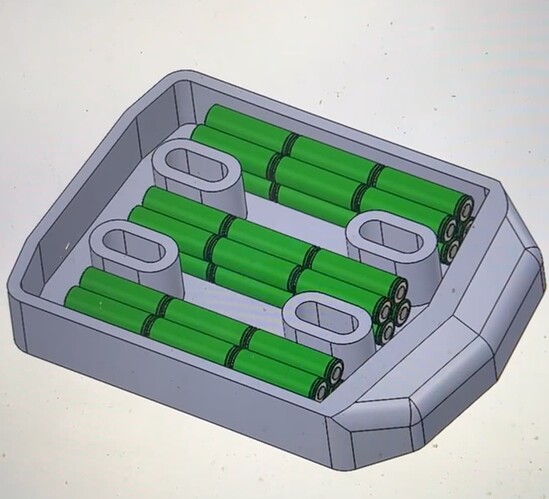

I had this in standby for a while but plan to progress on it (and yes it’s a lot of cells !)

It’s 45mm high so I can easily host 2x21700 cells blocks and still plenty of space for ESC.

any good 3D designer that can move this forward for the community? The overall cost of this to be CNC is around 600 euros on big milling platforms… so very reasonable

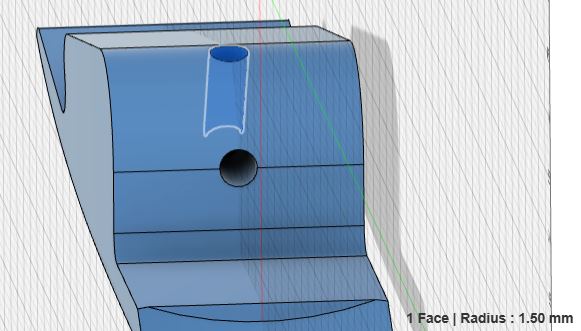

I’d change the design to make it a plastic cover, could be resin or sls 3d-printed quite reasonably if there are metal standoff rings taking the load from mast to board.

Could be tried with stacks of m6 large diameter washers😀

yes, exactly. I also got the option and it’s half the price if you go for P12 Nylon. That’s why you have big channels that will use metal standoff to take the load as you’re pointing it. Walls are 10mm except the bottom and top one.

I just need to find out how to make rubber gaskets and add the few screws holes / tabs here and there

Nice 9S4P battery. If you look at the VORTEX pictures shown by @brycej, if aluminium, walls could be thinner around 5-6mm thick + 3mm for top and bottom