This is what the inside of the motor looks like after 100 hours of saltwater use with no water proofing except for corrosion x on occasion.

Could you also take pictures of the magnets?

I just put it back together and mounted/taped to my mast, but next time I pull it apart I will upload pictures of the magnets.

Do you mean from the parcel to the sea without even changing the bearings ?

I would also be grateful if you could make a video of the process of treating the motor with corrosion X. My rotor and stator rust even in fresh water when treated with epoxy.

Yes that is correct, no initial bearing change. Straight from parcel to soak in corrosion x to seawater.

That does it; I’m bathing in it.

It’s a huge part of maintaining my commercial e-foil as well.

I have a can of corrosion X, can i just spray inside instead of bathing it? thanks

Sorry got my threads mixed up. Just spray enough to that it coats everything properly.

You can spray the inside but I think soaking it for 30 minutes or so helps it get inside the bearings and the copper windings better.

I probably should spray the electronic inside the waterproof box and do you think i can spray the battery too? Just in case water get inside and it won’t ruin the battery? thanks

Hello guys

Inspired by this post I decided to build a Foil drive for light e-foiling and Assist.

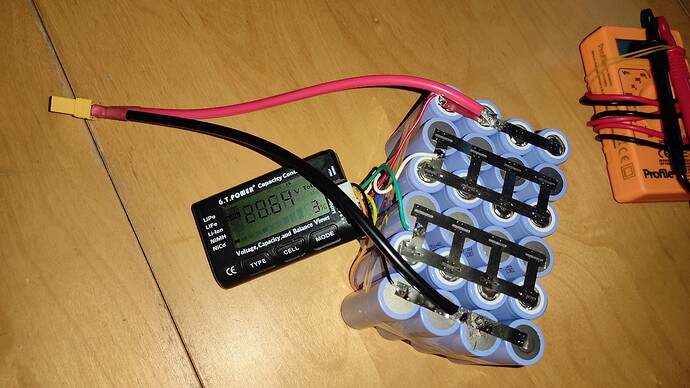

I built on a gong X-over Xl, with an epoxied 8364 120kv, 6S4P 21700, flycolor 150A and 3D printed prop from Leachim.

Succcesfull points: everything seems Waterproof, and nothing burst in flames yet while soldering.

Less successful : i tried on a SUPfoil board (7,6ft) and remained stuck to the water. Speed was quite low and I couldn’t pump on foil. It seemed punchy and torquy enough on startup.

I then set ESC timing to a higher value, and measured draw current + RPM.

Motor seems to spin at around 3000rpm(full throttle), but draws only 50Amps. Which makes it functions at half its power (3000W).

At 3000rpm and 24V, I guess that the load is not enough.

I modified the propeler to make it triple blade, and will test it tomorow.

Or maybe I need one with higher pitch.

What do you guys think ?

This forum is a goldmine, thank you for all the information already

(PS disregard the very messy shed, my wife hates it)

Cheers

Alex

Max mechanical power is at around 70% of free spin rpm. So 0.7×120*25 = 2100 rpm. Increase the pitch and/or diameter until your rpm under load are like that. Mind you, motor efficiency at max mech power is quite low

They work well as an assist or Efoil when up high on the mast. As you move further down the mast the level arm increases which requires more weight forward on the board and more power from the setup. Try mounting the motor up high on the mast. With this setup (6s) we are generally at the lower power range regarding starting on an Efoil.

Okay. Thanks.

Before switching to bigger Esc and higher voltage I will try higher on the mast. Clever.

I can fathom how to print the prop to maybe 120%, but anyone know how to increase blade pitch ?

I had good luck with the b series prop designer. Aim for 2000 watts or so @2100 rpm. If you have experience with freecad you can use my prop file, just replace the step file

Hello! Who tried to give increased voltage 7s on Flycolor 150A 6s?

Help please

I have just gone from a 6S to a 7s battery in my foil assist.

I am just getting everything set up and have one problem I could really get some help with as I have run out of ideas.

I have a 6384 motor. I have moved from the Flycolor 150a 2-6S esc to the Hobbywing flyfun 120a 2-8s to allow for my new battery.

I have everything wired up but when I pull the throttle I get a stutter from the motor in the throttle range of 0-30%. Sometimes it will cut out altogether. Other times it will get past the 30% and then behave totally normally from 30-100%.

This does not occur with the same motor, remote and receiver with my 6S battery and Flycolor esc.

I have checked connections a couple of times and cannot see any problems.

If any of you have anything I can try, please let me know.

Much appreciated.

Further to the above, if I get the motor past the stutter I can then go up to 100% throttle and then drop all the way back down to 5% throttle very smoothly. The problem appears to be just on start up.

Thanks.

James

Will it be possible to ride a hydrofoil with a 6384 120 kv motor and Flycolor 150A 6s ESC without a paddle and a wing? Can I watch the video?