Hand warm, not more. That is with my Easyfoil Easydrive plus. I did notice this battery pack gets slightly warmer than the 12.6Ah stock battery. Didn’t test the DIY unit in water yet.

Assuming it hs that one: Samsung INR21700-50S 5000mAh - 35A - 21700 & 20700 - Li-ion - Rechargeable batteries | NKON

wouldn’t I get 95A max in the 8s3p configuration?

105A but you can‘t go that high for long.

Right. The 6374 is rated 60A contiguous so I’ll have to current/power limit anyways.

It can probably go higher, the rating is meant for operation in air, not with submerged watercooling. My 63100, which is rated 80A, can take 160A phase current.

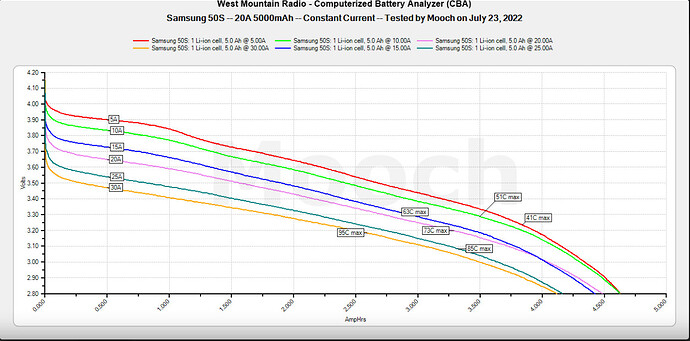

Never believe the rated specs from a manufacturer… Here are real world specs with the temperatures that the cells reach when run at specific currents:

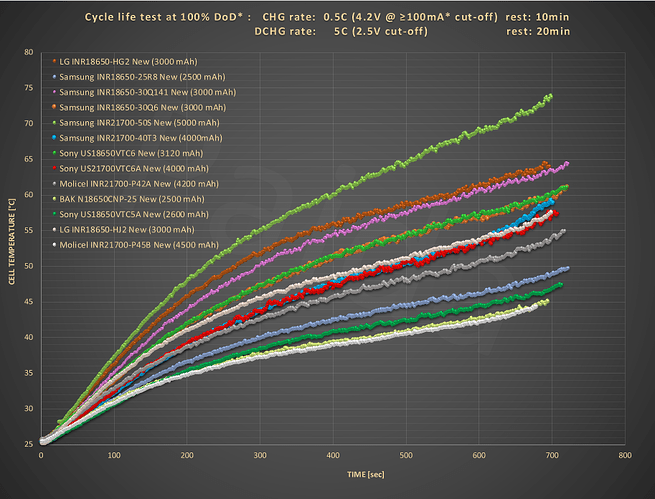

Cell discharge definition is one thing but not always critical to the useage. Duty cycle should be taken into account when it comes to the heating in real use. This is from Pajdas tests at endless sphere.

If we define an acceptable cell temperature at something like 50 deg C then it can be used about 3.5 minutes continuously at 5C discharge and that’s surely more than needed in a foil drive, right?

If we instead look at the use case with 10s burst to get up on foil then cell heating is 2-3 deg C.

A lot depends on use case. For pure foil assist, then yes it should be ok. But at 8s the current will run higher. If the system is used for a few minutes then the cells will heat fast and battery life will significantly lower.

I run 10S4P Samsung 25R cells in my one assist and after ±7min they were way to hot to hold. A lot also depends on how fast you open the case after foiling to check how hot the pack gets…

I’m sharing various parts like cable guides, ESC housing and battery base plate for my Foil assist: Thingiverse - Digital Designs for Physical Objects

Any details on the brass inserts and screws? Size?

M3 brass inserts: ruthex M3 Gewindeeinsatz – 100… https://www.amazon.de/dp/B08BCRZZS3?ref=ppx_pop_mob_ap_share

M3x8mm

I heard from someone that the Gen 2 systems have a foam pad on top of the box. Im wondering if this foam pad (probably closed cell) creates a water-tight seal between the box and the board and therefore creates a “hole” in the water where the signal can pass through box and board to the top surface of the board where it can then reach the controller. That way the signal never has to pass through water. It does have to make it through the carbon board though.

get the molicell P42A 45 amps for 4200 mah on 3 p you will get 135a as per the book, so 95a easy !

I see screws holding the remote receiver to the backside of the esc cover. Nut on the topside or super short tapered screws?

Interested to know to to cool the HV3. Should I fit it into my box direct with the branded side exposed through a hole and sealed, or should I take that off and use a fin block for cooling?

Also, how to remove the top cover, do I just force with a flat blade?

When you say a light coat of epoxy, do you mean epoxy enamel (Paint), or epoxy resin? I assume epoxy enamel is used to coat the inside of the rotor?

Hi all. New to this forum and building my first rig with a 6374 motor, 10s2p pack with smart BMS.

Has anyone used and had success with Flipsky ESC6.7 70A base on VESC6.6 for their setup?

I am wanting to buy something fairly simple to plug and play. I am fairly constrained with space in the enclosure I am using (same box as Assist Plus) so don’t want to use a massive VESC. Plus my knowledge of programming these things is literally 0.

Any help appreciated.

They overheat after about 13sec. I managed to push up to 100a though it but it would always cut out because of heat. Even when I pushed 40a it overheated.

hey mate, I did it but TBH the actual alu cover does the job. If you want to improve cooling, you can explore removing this branded … but you will have to manage an area which is more deep than the other.

I suggest you to keep it and sand it slightly, apply thermal paste on an alu part that will be your inside/outside interface. Make sure you use 3M 5200 to attach the alu part and add enough to keep your box waterproof.

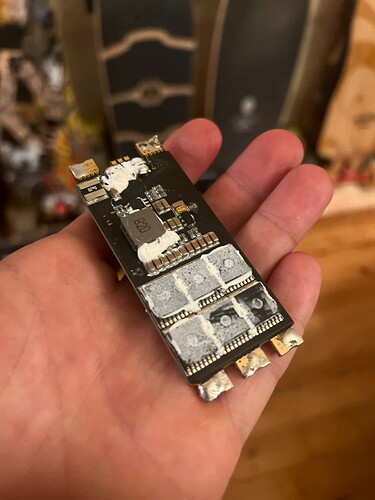

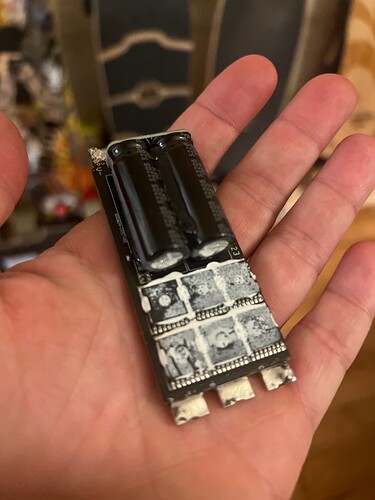

for science

to show you how I did it