Remembered another mod I did to the setup. I was getting saltwater inside the mast pod. It would slowly drain out but left a lot of salty residue. I decided to fill the 3D printed pod with epoxy resin. Used about 125ml off West system. Small weight gain. Pods are now rock solid, I don’t think you could break them with a sledge hammer!

How does the mounting scheme work for the pod?

I think I’m gonna build one of these kits. What motor did you use, and what motor would you use if you did it again?

Thx!

You still working on a kit? What motor would you recommend I get to start this project? Thx!

Getting close to testing my build using the flipsky 65111 motor. Just waiting on my Maytech remote to arrive. Does anyone have a file for the mount that holds the remote on the paddle?

Yeah the idea is still there. However a baby arrived ±1 month early so quite a few deadlines have shifted haha.

Busy with a solid CNC build right now so that I can make all my development much faster!

So, is all your progress top secret, or can you tell me what motor to buy that is the closest to foil drive performance without much extra weight?

Remote mount for maytech, I drill and tap the holes to tightening the mount on the paddle shaft. I also add a 1mm piece of foam rubber to the inside of the remote area (one side only), this allows the remote to press in tightly and keeps it from coming out.

Currently out of town and trying to paste link from phone. If there’s an issue with the link I will update it in a few days

Thanks for the reply Tim! Link doesnt seem to be working but no worries. I can wait.

So ive been testing the following combos in my pool (static testing):

-Flipsky 65111 + Flipsky VESC 6.7

-Flipsky 65111 + Turnigy Aerostar 150A

Both ESC’s are similar in physical size. Both are super small and awesome for fitting into a small, low-profile enclosure.

I want the VESC to work so badly…because its a VESC…and because it can run FOC… but even though it says its rated for 70A continuous there isnt a prayer of it actually doing that. If i run WOT with 70A battery current limit, after about 20 seconds it slams into the temp limit then drops down to like 30A battery current until you back off the throttle to let it cool.

The Aerostar ESC on the other hand rips. According to my clamp meter, it pulls like 130A battery current. And it will do that for at least 30 or 40 seconds and hardly get warm. Meanwhile, the motor connectors start to get hot. I wish there were a way to dial back the current limit on that thing like you can with a VESC.

Has anyone had any luck with putting a bigger heat sink on the flipsky VESCs? Currently, i have the temp limit set to start at 85 and end at 100C. I dont know how much hotter I could set it without risking damaging the controller. It would be awesome to be able to run with the control and hardware safety features of the VESC but not sure this thing is going to cut it. I guess the intended use of this whole foildrive setup is to just use higher power for short burst in which case the VESC might be able to handle it.

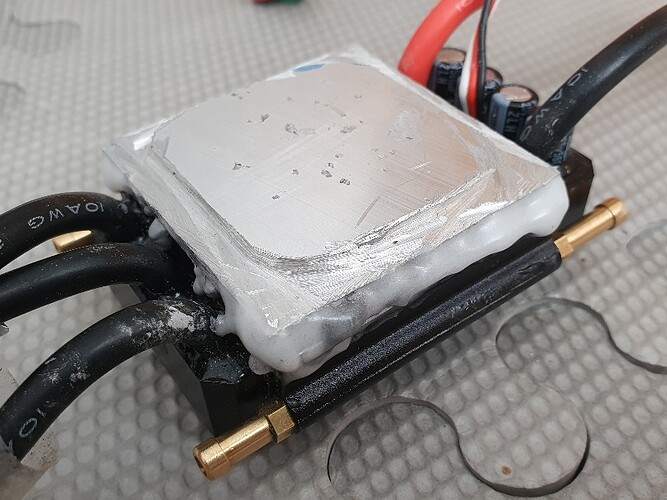

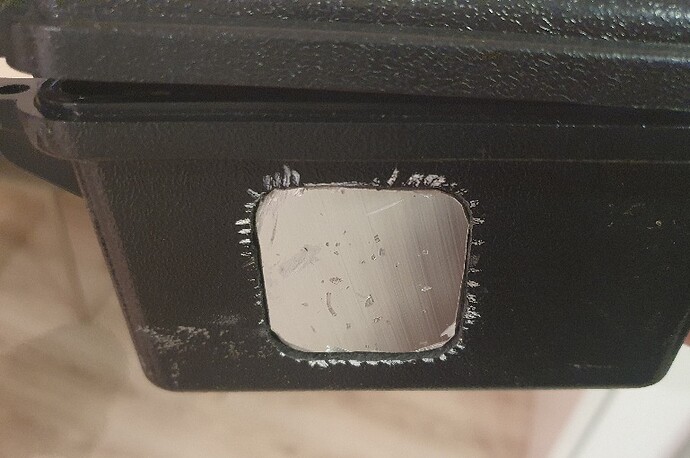

I was facing similar issues, so I glued my ESC to a 6mm plate with thermal paste + epoxy, now I have to make a hole in the box and glue it there. As you can see in the pic, i removed 3x3mm of the alu plate to improve the bond with the plastic box and avoid sharp corners in the region i have to remove. Hopefully it’ll hold.

I didnt want a hose with salt water inside the battery comparment. I hope this was a a good idea and that the plate will remain watertight. The epoxy is rated to 150ºC, so should be fine. I’ll test it this weekend and report back.

Awesome! I have used 3m 5200 to glue things through the wall of waterproof enclosures before. That stuff is crazy strong (and crazy permanent). Might be a good product to seal your aluminum plate through your box.

That looks like a flycolor/hobbyking 150A esc? under what conditions do you find it starts to overheat?I think others (like @Foil_A_Lot ) are using that same ESC without overheating.

With a 172mm prop… and i was using it to cruise around to see how fast i could go. As a foil drive (10 sec burst) it’d work just fine even with this prop in my 70L board. It could start effortlessy even without a paddle

Btw, thanks for the tip on the glue

Edit: just took a look at the brouchure of the 3m glue and looks like a much better choice than epoxi. I’ll order it online, so ill have to wait till next week to try it.

In the meantime here’s how it fits

First off, proud to report a successful first test flight today. Did 15 minutes of slow efoil style circles today. It works! I’d like to take credit, but the brains of this operation is entirely my friend Pete, and much of the credit to the group members here for parts, knowledge, and inspiration. It takes a village to motor this kook.

Jsonnett: we are using flycolor ESC. It seems to have a failsafe built in that once it starts to overheat it goes into limp mode. We found in testing that running it in continuous power, it won’t last long, maybe 10mins, then requires a few minutes before it’ll power up full again. On Pete’s first test, he moved from flat water into the waves with the short bursts as intended and it worked for another hour…so wasn’t a battery issue. His initial testing was with a VESC (not sure of brand or specs but can find out), he was only getting half power. With the flycolor ESC, he said the propulsion was 30-40% more, which is difference between getting up on flat water or not quite.

Pablo: what is your goal with that esc? Is that so the heat can dissipate outside the box? Nothing those brass fittings on the esc, designed for water cooling? Could be a fun side project to figure out some way to build cooling into the project with those.

Sounds pretty good!

You mind posting your build specifications?

I see several different motors used successfully for DIY foil drives. I’d like to learn from you guys and get the most optimal motor. Looking for light weight, and durability.

Any of you guys with working setups wanna share your thoughts on the weight of your DIY foil drive setup compared to the “Foil Drive”, what components you used, and what you’d do differently on your second build?

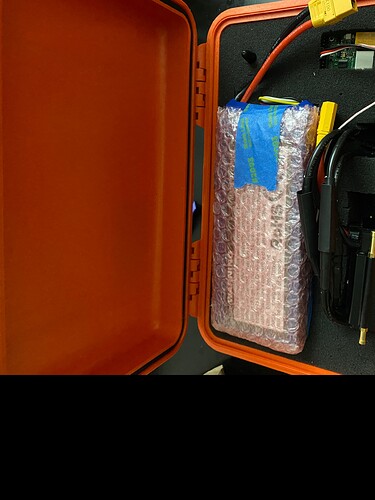

I’m hoping to build a foil drive as my next project. I already have the remote, ESC, and battery cells. Just need to decide on a motor, print a mount and a prop, and a remote holder, and find a waterproof box.

@juandesooka the goal is to dissipate the heat into the sea. My board has a low volume so every time I stop the box is submerged. So as long as it does not fail, it’ll be good enough to ride for a couple of minutes, cooled again in a sec, while maintainance free and just as easy to install as before

As for the fittings, yes, it’s a flycolor marine esc and i could have used it, but I didnt want tubes with salt water inside. Also I don’t know how brass will behave in the long term if salt water is left inside. Galvanic corrosion might also clog the cooling line??

@Flightjunkie my setup weights 3.75 kg, but i have a bigger battery (16Ah vs 12Ah in the commercial foildrive). you can find all the specs here DIY electric foil assist. Steps+pictures+cad files . Seems that all 6374 and 6384 work fine, you just have to try different props until you find the one you like.

Currently working on my drive. So far the motor is epoxied. Motor pod is complete. Next is printing a prop and playing around with sizes. Then finishing up the controller holder. Hope to get some testing in on Friday. Major goal was to make this an affordable project.

Using a Flycolor 150A and a 6374.

I may try making a folding prop once I get everything else squared. It’s been a straight forward project so far.

Is there any reliable information about which ESC is used in the original Foil Drive Assist?

Not that I know of. I wouldn’t be surprised if it’s something similar to the fly color/hobbyking tho. I just got the identical enclosure they are using from polycase and the fly color fits in there perfectly.

They have an interesting area on their website for service info. It’s password restricted. I bet it has pictures of what’s under the cover on there and they don’t want people to see that it’s just RC Boat parts that make these things tick! Haha.