I caught some waist height waves today tide was up for our local.

It’s not easy getting up high on foil so motor is out got it once and everything smoothed out but I had an issue with my prop started vibration again I got it home and for second time the bolts on props had come loose again. I’m putting flipsky 2blade prop back on to try.

I’m also getting what only feels like motor slipping with funny sound kind of hard to explain.

Will try again with original two bladed prop to see if it does it again.

check this out https://www.youtube.com/watch?v=249XdY_CB0Y&ab_channel=VinceRidgeFoil

i think this is the stuff he uses Sotel | UHU UH47845 Gel 80 g

clear gorilla glue could well work instead (hard brittle so easy to pick/ drill out Gorilla/GZD Super Glue 3g /6g /15gGel /12g Brush & Nozzle/50mlCRYSTALClear/60ml | eBay UK

which are these and have you managed to test?

I have finally gotten hold of some FD aluminium blades and they are a lot thinner than my maytech stainless ones (pretty much the same shape and pitch).

@Flying_Rodeo do these work in FD hubs? BLADE for Assist Motor – HighFly - WaterSports

Tested all, just havent managed to record data on all and dues to a newborn havent even got in the water yet this summer ![]()

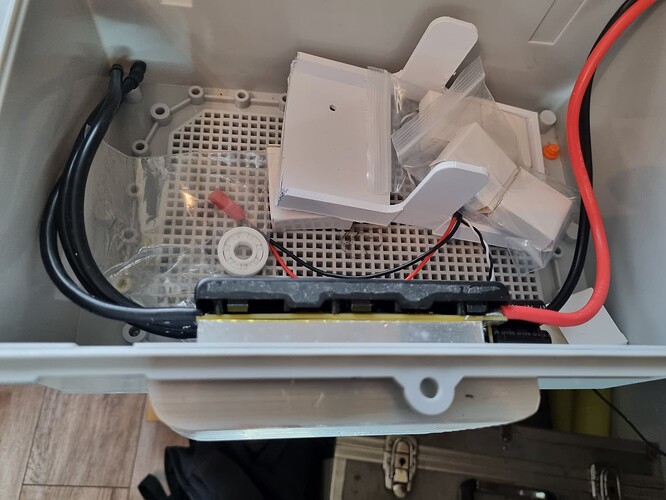

Hi, I increased the cooling surface of my ESC and cut an opening in my box to have the ESC inside, the cooling element outside of the box.

Full load test with closed and sealed box still needs to be done but the heat transfer appears to work nice.

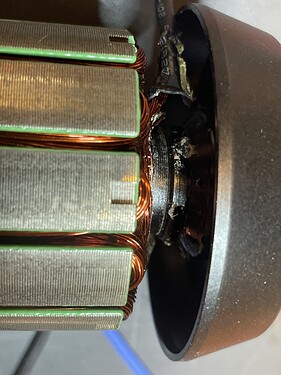

I also managed to remove the stator case as shown in the video. Just one remark, my wires were glued to the case and I almost tore the wires when hammering up that case as they sticked to the top while I was moving the stator downards. Do it carefully until you get a gap, then soften the glue with a heat gun.

Nice setup! i’m working on the same but only differenceis with the flipsky 75200 controller which is quite large. Was the 6384 compatible with the maytech 160amp esc waterproof. I had my eye on that but was told it was not compatible @airtimeasto

Yes it has been working fine on 12s with 160amp esc.

however Im not getting as much run time as my mate on his foil drive. He gets 40mins i only manage 20 to 30 on my HA980 wing.

So im going back to 130 amp water proof esc with bigger wing HS1550

Ive gone back to Batery in my board. AUW 15kg.

I still want to drill into mast and put pod intergrated.

If this goes all well ill make mold of electronic box and do carbon/glass layups

Do you know what technology and plastic material is used to 3D print the propellers?

A while ago, I had the hub that holds my three propellers printed using SLS nylon technology, but I don’t know if that same technology and plastic would be suitable for my propellers.

Yes I got told that too but I’ve been running it and it’s fine I did change bearings out to SS ones ceramic fell apart

I haven’t printed my own props yet I have been using flipsky 2blade and KParts Ali 3blade props. I might try the foil drive props I read here somewhere people are using them with good success but do we need a different adaptor

I have been fdm printing fixed props in pla-cf and plaq+ and they hold up well. For a folding prop the slam from 0-full power probably is a problem.

Resin printing has come a long way in terms of engineering grade resins. I am testing some stuff now.

Does anyone have the CAD for Michobby propellers? I’m using the original plastic ones and they work great, but they’re very flimsy. I have the means to machine them on a CNC but I don’t know how to design them.

Can you tell me the length of the strap? Is it a voile strap or similar?

Did you ever put this design to test or function? this is the missing part to what im trying to build.

Thanks Lud

Funnily enough no I didn’t. I have an endless compulsion to improve things so every time I print it I find a minor design flaw and then make changes. Realistically It would actually work as is.

I’m now working on something that would benefit both the DIY and commercial market, but it just depends on how fast I can get it done. I’d like to have it ready by the Northern Hemispheres summer, but we’ll see.

Is the a V1 or V2 motor ? And what POD system is that attached to the mast? Thanks

Ciao, I was thinking to change my Maytech 6374 with Maytech 6579 but I have Kparts 3 blades too, so maybe better considering Flipsky 6384. It is also cheaper and it should increase performance anyway. I am 80 kg and VESC is 70 A.

Thanks

Perhaps someone can help me. I have been using my self-made Assist for a few months, and for the last few days it has been malfunctioning. After 10 minutes of use, the motor would disconnect and it would not accelerate at all. I use a Sequre 12200 ESC and a 46V to 5V transformer to power the receiver. After much research, I noticed that when it stopped working, the receiver turned off. I discovered that after 10 minutes, the transformer that goes from 48 V to 5 V stopped working.

It’s really a cheap part, but I’m very surprised that this part failed after only six months of use. I’ve already bought a replacement. Can anyone find a logical explanation?