Hello.

I used acetone but thare is specialy made thiner for varnishes used in electromotors.

You can check at local supplyer that sells varnishes enameld wire and isolation for motor rework.

Neodyms aren’t machined to size, they’re sintered since they are toxic and flammable when machined. I’ve gotten 5x5x50 magnets for a motor build and there are plenty of thinner dimensions so it can be produced but i guess manufacturers skimp on the costs of putting 2 magnets side by side for the long rotors in these motors. It still doesn’t make sense, surely someone has got an engineering degree in the design team - beats me why they do these poor choices.

Can you share link whare did you get 5x5x50 magnets?

I wiould be great if i could make 10pole rotor for 66160 motor.

It was too long ago to link but i got it on aliexpress. So many sellers and hard to know which are legitimate…

Thanks i actualy foune some on aliexpress but all are N35 rated.

I would like N45 or eaven N50.

I think i will for now use stovk rotor.

nice.

Winding are looking beffy.

This is how mine looks now.

It spins without load, tested yesterday.

Now to see how will work under load.

dou you have picture of back side after rewinde?

That is substantially better looking!!!

I hope to be able to show the motor in operation soon. The preliminary test in the bath was passed - the motor runs smoothly and quietly, no oil leaks were found in the seal area.

im coriouse how will it work in water…

It looks much better then stock…

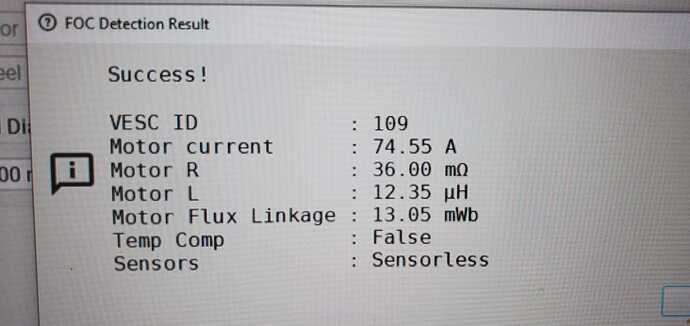

Did you mabye know resistance of phases now after rewinde?

I have not taken measurements and at the moment I do not have the opportunity, but as soon as it appears, I will definitely do it. If you are interested in the details, I can note that the stator was originally wound with 0.315 wire and rewound with 0.335 wire.

Can i ask you a favor?

Can you ask shop whare you rewinded your motor if thay can tell you how its wound, what configuration.

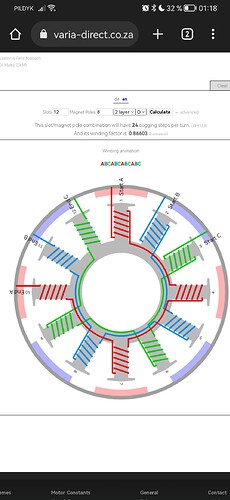

I have wound mine with configuration that i get from calculator for 12n8p motor, bu i got phase resistance of 0.065 ohm and original it was 0.035 ohm.

I could not unvinde my beacouse of to much varnis, i had to hammer wires from slots, only menaged to count how much wires and how many turns thay put in.

I suspect it was wound differently then i did but i cant figure out how.

Thank you, i will be greatfull.