Hey All,

I am Marc, from Rotterdam in the Netherlands, first build

Before I start a big thumbs up for this forum and the people who are sharing so much info and building boards, brilliant! The thought of flying over the water is bringing a big smile already, now I have to start.

Just browsing through the posts and slowly getting to understand how matters work and writing down what I need. @pacificmeister, @Hiorth, and many others as well, thanks!

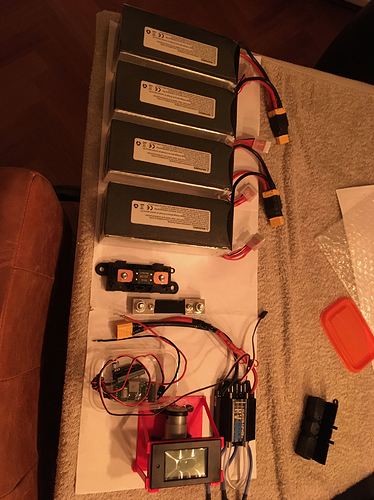

One of the first things I would like to work out is the general lay-out of the electrics and what is exactly needed for a board. The choice of battery, ESC, kill switches, etc comes later (I have still quite a few threads to read about these topics). What i was able to find/understand I put in a small diagram (sorry for the quality hope its clear). But, I think I still might have things wrong or missing. Would be great if I can have some feedback on this diagram.

Also looking around to source parts. I checked with a Neugart gearbox importer here in Holland, delivery time: 19 weeks because the economy is doing well. Guess its gonna take a while haha. Anyway, lots to do!

WIll keep you guys posted on my progress. Possibly needing more help, too!

Cheers, Marc

. Leash ever since. Good luck.

. Leash ever since. Good luck.