I’m building one of these, one question: Are there any things to consider when getting a tow line? Looking at options, since it’ll be my first time towing behind something i’m in need of advice, does it matter what i get, any particular length, is any waterski/wake rope ok?

I use a 25 foot wakeboarding rope cause the handle is less wide than a ski rope. It really doesn’t matter as long as the rope floats. I found with shorter rope it is easier to make tight turns, but it was harder to stay high up on foil.

My first rope was just a polypropylene rope that had a piece of PVC pipe for the handle. It works well, but I would add some 2 part foam so the pvc handle could float.

Just about any water ski / wakeboard tow rope will do. They float, and are durable. I picked up a cheap one on Amazon a couple years ago, and it continues to serve me well. Initially I had 5’ of coil pipe insulation attached near the boogie, but later removed it. While the rope occasionally gets twisted under the boogie’s mast after I let go during tow-in, it’s rare, and has never been much of an issue. I’ve never had it tangle.

Also, most ropes have plenty of excess. Mine is about 10’ in length and works well at that length.

I’ve extended the rope a few times, with the intent of practicing pumping around the boogie, and continuing. Unfortunately, the signal between my Maytech remote and my receiver starts to cut out when using the longer rope. …I need a BREmote.

100ft? 10m? 10ft seems exceptionally short😀

I use a 10 meter long 6 mm floating rope with a short carbon tube as handle. Bought a piece of foam used for bike handles so it floats and is a bit nicer to hold on to.

The carbon tube is of course totally unnecessary and you might as well use a broom stick. Shorter rope makes the boogie more responsive but stops you from doing longer carving turns. My next tow boogie will have a slightly longer rope.

I was wrong. Actually, it’s 15 feet.

I would’ve thought a 3m line would pull you too much downwards but i see that the working span is quite large, i’ll just get a floating, no stretch line of some kind😃

There are some drawbacks: you need to move a little away from the jet created by the propellers. But there are also advantages – better control. At the start, I can raise the stern of the tow boogie with a halyard, not allowing the bow to go up.

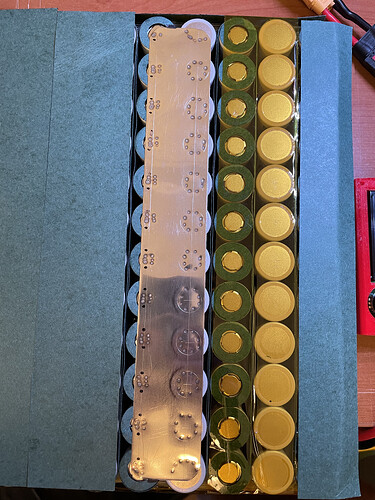

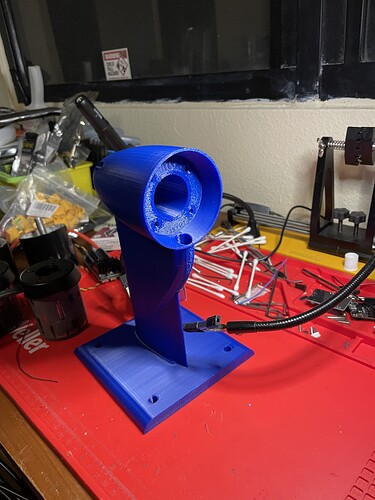

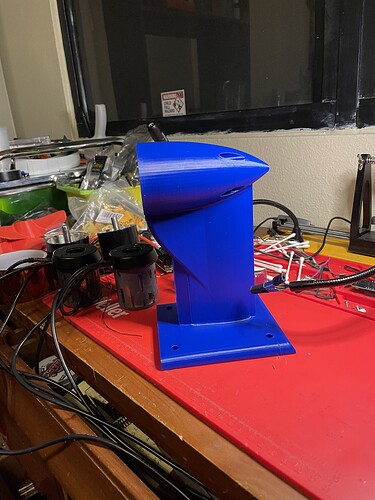

On my 3rd dual motor boogie build, motivated by @hangloose to make things cleaner. Trying some new things and practicing with fusion 360 a bit more. I am building a 12s12p pack for this one with P45B’s, so more time on the water, flycolor x-cross 120A ESC’s (love em), potting the motors, new motor pods and gonna start trying to make different props to try. I am using @hangloose connectors, which are awesome, thank you for sharing!! Almost finished with my battery build, motor pods printed and fitted, and starting to print the first set of 3 blade props, might be too aggressive on this first go, but at least it will give me a starting point. Ive been using ASA for my other props with great success.

Nice work mate ![]()

Do you laminate the props?

Thanks man! Since I started printing the props in ASA I don’t laminate them and they have been working great.

Well, had a speed controller explode today. Haha… I think I went too aggressive and stiff on the propeller I made. It didn’t work very well anyways, but when I hammered on the throttle with a fully charged battery smoke blew out of the case. Luckily the battery didn’t get damaged and the other speed controller and RX board didn’t take any damage, so hopefully all is good. Time to make some changes to the props and try again. I’m determined to build my own prop.

Does the flycolor hv3 not have thermal throttling like a vesc?

You can set it on BlHeli in " Temperature protection "

I also use "current limitation "a lot to preserve my battery

Yes, I had temperature protection set to 85c, but did not have current protection on. I’ve been running this setup flawlessly for months. One or more of the mosfets blew up. The only thing i changed was the props. The battery was full and when i got in the water i gave it a full pull of the throttle to see how the props would feel and the speed controllers cut out, which is what they’re supposed to do, but then i decided to pull the throttle a bit slower up to full power and that’s when the smoke left the case… haha. I think I’m going to start turning on current protection.

I think building your own props starts with learning fluid dynamics. Personally, I don’t have any knowledge in this area, so I use blades designed by more competent people. The parameters I allow myself to change are the size and pitch.

I completely agree, but it’s definitely interesting to me and I need to put more research into it. My personal goal is to at least build everything from scratch and get it to work, if even sub optimal. I think it’s a great way to get better at CAD design, etc… I love the prop you shared, so maybe better to stick with what works.