I soldered mine, then tested before potting, quality seemed acceptable. Always the issue on ali stuff, some variation in quality for the same products sometimes.

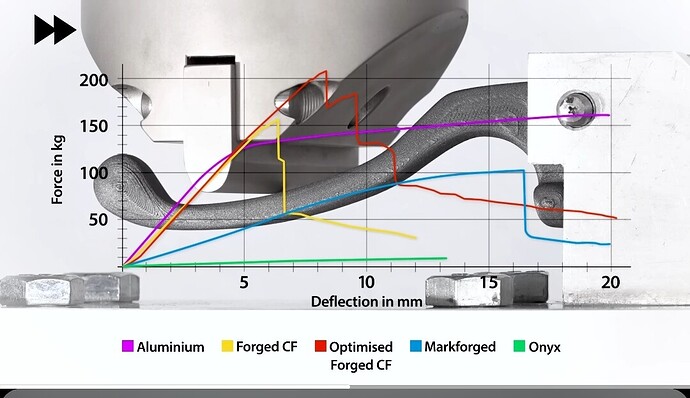

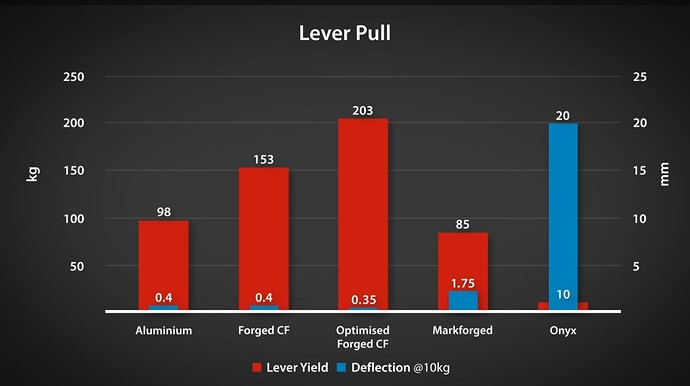

Yes, this video proves that forged cf is almost as stiff as aluminum or optimized cf and even much stronger than aluminum (the force when it breaks) while being lighter.

The 3d printed version is without comparison less stiff and less strong.

Seems to me that the test performed on the lever is similar to the load applied on prop blades .

'https://youtu.be/eewlYa6IQPg?si=2Eb_4pavPkd64fiI

No, it’s not really the same, it is easy to align fibers in the loaded direction on a lever, totally different thing on a blade that has an area. This is why i think the random(ish) distribution of the chopped fibre might be an issue. I have tried it ![]()

But the forged CF is not aligned to the lever and still stronger than the aluminum. the Optimised forged CF is partly aligned with the lever.

Im sure the forged part will be stronger than a 3d printed part.

But i could image, that aluminum blades are still stronger and stiffer (just guesstimating it)

Yes, but the lever is not a good example, overbuilt. Not optimised for thickness or weight, a propeller blade is not the same. Apples and pears.

If we put the energy and cost into making carbon fibre parts, then we’d better use it to it’s best performance.

Tested the new blades in the water. It was cold ) They passed my personal stress test. It consists of the following: I tighten the propeller so that the blade turns with force, fold it and quickly press the gas. Usually the blades break at this moment. But not today. Today only the PLA blades broke ). It is super nice to ride, easy to control and maintain altitude, compared to other printed blades I did not notice the effect of loss of efficiency at 70% of the gas, that is, they are quite rigid and do not straighten at these values. Of course, one ride is not enough to make unambiguous conclusions, but so far I like everything. Also today I learned that the reason for my uncertain riding is not so much the mast and wing, but the board. I took a 50 liter board from a friend and wow - everything immediately started working out. Although what could you expect from a board that springs when squeezed with two fingers.

The fiber to matrix ratio of forged carbon can be better than other process, in an ideal world aligned fibers would be ideal, but I don’t think it really makes a difference for our use case, as the fibers I used were around 20-30mm long.

I tried to stand on the motor bell/axis with the blades laid down on the floor and it did not break or bend a lot, so I think the strength is already sufficient for sure.

There is still need for quite a lot of finishing work, maybe my mold is not ideal.

Did not manage to test it yet, will report back.

I’ve tried it and when you add the fibres it gives a fiber distribution that’s following your mixing order and this gives a less than optimal layup.

Important thing is maybe if it’s good enough and better than the 3d-prints. Sure, it is. And thanks for the tests!

I doubt the fibre content can be better. Lay perfect layers and apply the same pressure, fibre content will be higher than WCF.

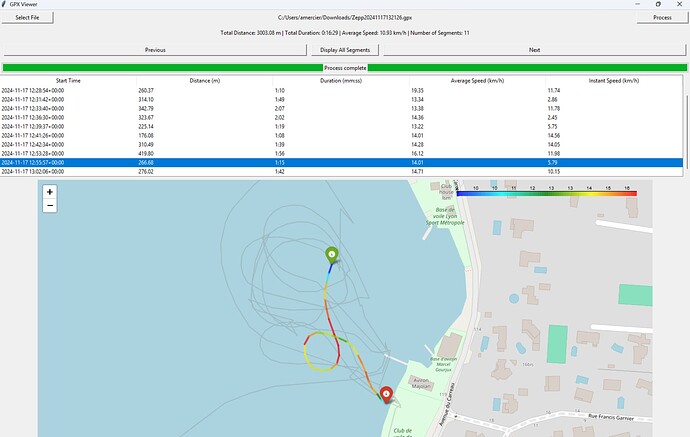

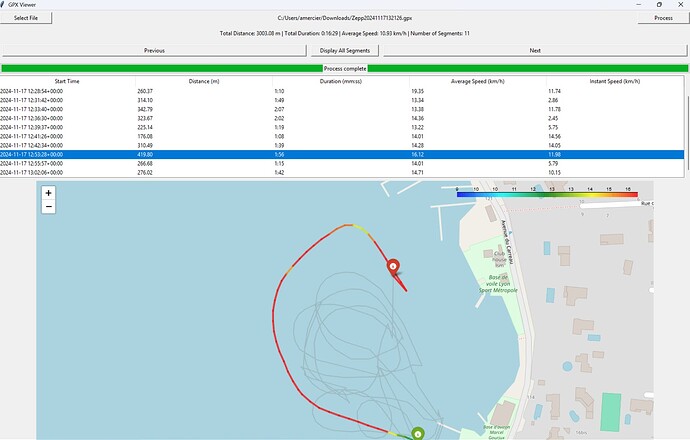

Next project is to improve signal and setup by making a similar style of extender.

Goal is to be able to keep the antenna on the board at all times, on both my boards, to reduce setup time.

If I have the antenna wires as I did initially, then I route another antenna with similar exposed wire right next to it, and up the board, I should get signal I think, and be able to reduce setup time and drag in the water.

I would use foam between both antennas to make sure there is no water between both exposed antennas.

Testing that asap with the cf blades ![]()

Hope it works as now my extension is cut ![]()

Got the foam in-between the antennas.

The board antenna is outside of the mast plate, if I want to run the board for pumping without motor. The FR4 fiber board was epoxied into the controller mount, but that could be easily implemented as a feature of the print.

Happy to report the antenna extension works as expected!

When pressing the maytech remote (v2) to the antenna patch/extension on the side of the board, I get signal also when remote and board are fully under water.

That makes the whole setup much cleaner and for me is more intellectually pleasing as I can use any board I want without permanent modifications.

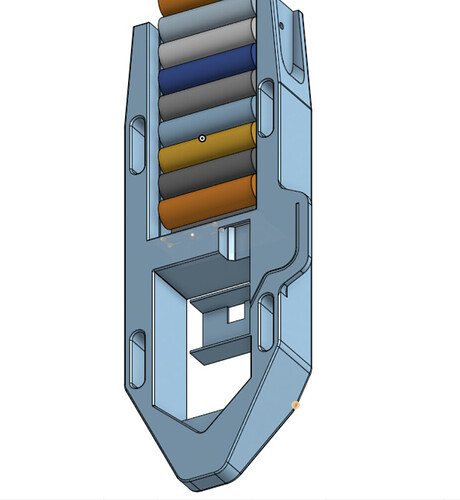

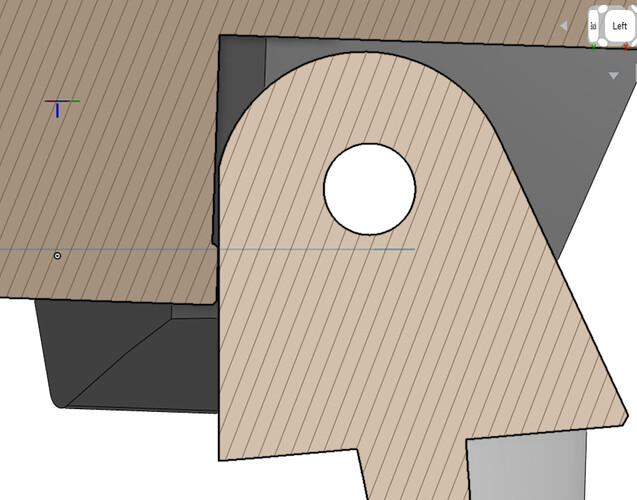

Keeping the model updated :

The CF prop was also tested, it worked well, but it does not fold out reliably in the water.

I will reduce the max fold angle on the hub.

The blade balance is also not perfect, I need a more precise scale to weight each blade and sand them to equal weights/thickness.

With the small board, 1401 and this light assist, I can pump motor out for around 1min15-1min 30

Video with the drone, pumping the setup motor out.

There is still high levels of flex in the mast/fuse connection, I need to make a permanent fix with shims, glue or tig weld. First step it to swap the fuses between my 1201 and the 1401 to see if there are some tolerances issues or if it is mostly the 1401 span and lift causing this feeling.

Impressive pumping skills!

Thanks, the perks of being landlocked ![]()

Printing a new hub, where the hub has a ledge on the part where the blade bottom out on fold. The goal is to reduce the friction area of the fold out position (from plane/plane to plane/line), an open the blades by 2° on folded position.

Today session was frustrating and humbling.

Super cold now, air and water, did not have gloves or hood.

First tried winging the DW board and 1201, I don’t really wing and the conditions were very irregular 10-30kt winds. Foiled a bit, but did not have a good time.

Then I went with the paddle for a short downwind run with the 1401. That was better, but did not manage to get on foil.

Then I decided to use the assist to end the session on a more positive note.

First my hub holding the forged CF blades disintegrated at the blades bolts plane, lost all the CF blades (now lost in this lake countless blades, 1 DJI NEO, 1 gopro).

I switched to the maytech and usual printed hub and blades. One of the blades snapped almost immediately, at the root of the blade and not in the pivot hole.

I think there is something with this very cold water, as it is the first time I have so many issues with PETG parts. Anyone with similar issues with PETG and low temps?

Cold water can really be humbling on its own, but having so many issues in one session, I feel for you!

Could you do the hub in forged carbon aswell? Or maybe just the area where the probs are held?

yes, that would eliminate such issues, but i’m not sure I want to spend the time to do it.

If I have enough scraps from my new pump board I will do another batch of forged CF blades.

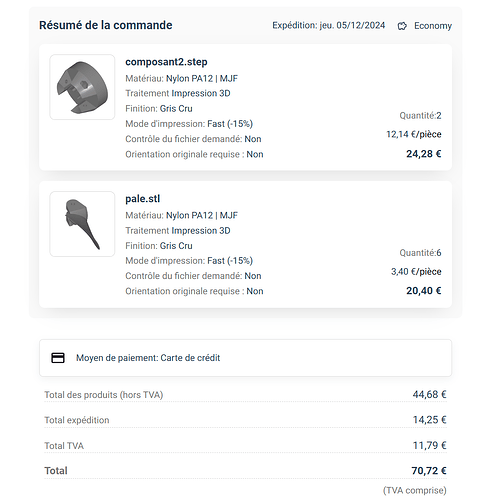

in the meantime, I ordered two full props, with hubs, in PA12 from WEERG for 70€ shipped. Also had ordered all the right bolts in Stainless steel, incl stop nuts.

Ordered alu printed blades from pcbway for 108€ shipped ![]()

![]()

![]()

Printed a spare hub at home out of PA6-CF ![]()

Why do that now, based on the fact I will be out of action for 2-3 months, is beyond my own understanding ![]()

Last session, I noticed a lot of play on the 1401, between the fuse and the wing. Tightened everything as much as I could, and that seemed to improve things slightly.

Also sanded down the tips in a more aggressive profile, to hopefully reduce the breaching stalls.