Hi guys.

Unfortunately the Maytech remote is still our best option. I hope another company comes out with a truly waterproof remote soon. But, in the meantime most of us will be using this product.

Many forum members trusted that this remote was waterproof out of the box and found out the hard way that it is not! Then, to make matters worse they found out Maytech does not stand behind their product. For all practical purposes there is no warranty. Some have said they were sold another remote at a discounted price, and some were just strung along. That being said…do these modifications at your own risk. Unmodified this remote won’t last a month, so I’d say it’s worth the risk of modifying. And to answer your question about whether this will void your warranty, my reply is “What warranty?” ![]()

I have put this guide together in hopes that it helps some of you keep your remotes alive as long as possible. This is a recap of the modifications I have made to my remote.

To start with. Do not get your remote wet untill you have opened it and inspected it. The quality control is terrible. I have a version 2 and my circuit board was potted, but some other users said their boards were not potted. In my opinion the boards should be coated with conformal coating and then potted in epoxy. So, open your remote and inspect it before getting it wet.

And second. Do not leave remote on charge. It will overcharge and kill the battery. I recommend only charging to 4.0v

Step 1. Use silicone modified conformal coating to coated any areas water could leak in. I always do two coats. Then let dry.

Step 2. Soak remote in corrosionX for a few hours then hang it to drip dry. Make sure to get the corrosionX to soak into the switch. Then simply towel off the outside and allow the coating to remain on internal components.

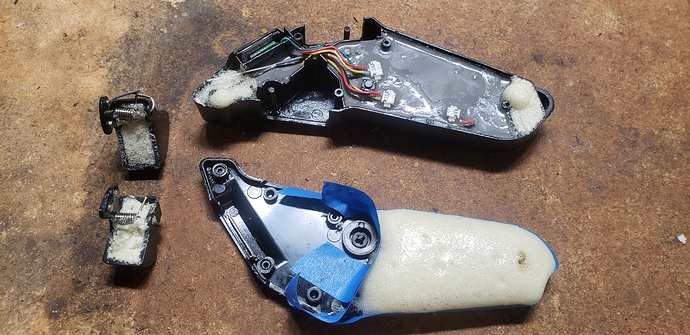

Step 3. I suggest using liquid foam to make your remote float. Clean off the corrosionX for the area the foam goes so it will stick. I fount that my remote floats really good once filling both triggers and the void in the top corner and bottom corner, and the backside of the cover. Caution. If you remove your triggers be extra careful how the spring goes and make sure you don’t break the plastic post the trigger pivots on.

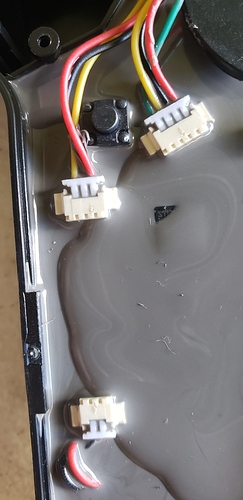

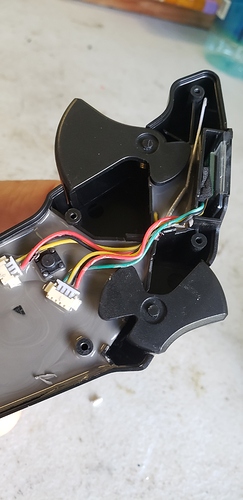

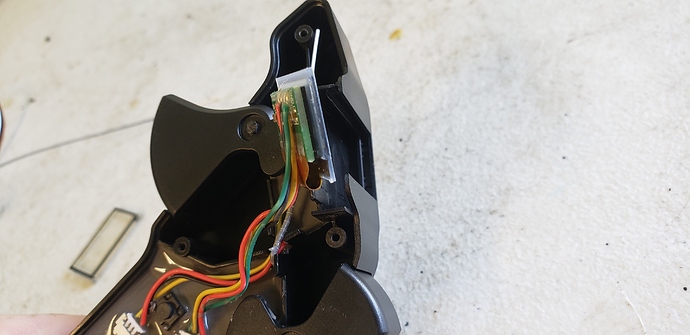

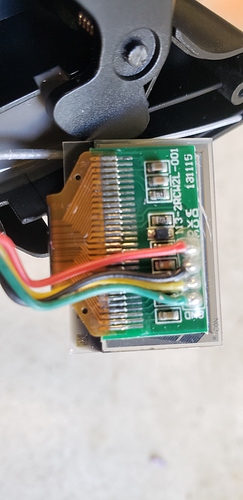

On my version 2 the potting was too thin. One of the circuit board chips was visible and the wire plugs were not coated. Clearly water would have leaked into the potting around the plugs and destroyed the board.

The screen did not look waterproof, but with closer inspection I see it was coated with conformal coating. However, I added two more coats.

Also, to prevent the look of water in the screen use silicone dielectric grease between the screen and screen cover.

I also use this dielectric grease to add a second waterproofing barrier to the switch.

I have learned a lot from this forum and I hope to help others by sharing my unconventional methods. ![]()

![]()