Sorry don’t have an STL for that.

There’s also the Flying Rodeo original solution here for two-screw (Axis) masts but that could be split in two parts for Naish/Gong three-screw masts

I don’t think its available to buy. Only comes with FR or Lift boards as far as I know.

Any link?

No link, just as food for thought as molding silicone could be not so difficult with 3D printed molds like @visor360 does for wings.

I tried to buy this from FR. no go. So im going to make my own from molding silicon.

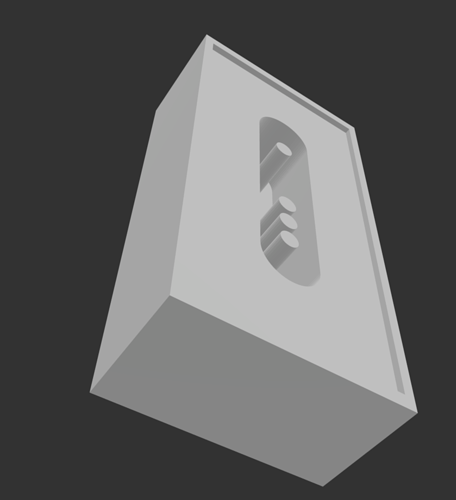

Here is a simple one i made.

I just bought a similar product and printed a mold. Do u use any mold release?

It popped right out perfectly. no release agent used. a tiny bit was missing as i had left some water in the mold. (i filled it with water to gauge how much silicon to mix)

Cool, thanks. Will try the same

Fantastic & clean work on your build(s)…

I love the screw idea, but have concerns they could be painful. Have you hurt yourself or drawn any blood from them, being raised above the surface? It looks like it could catch the skin pretty easily. I’m curious about the results in practice. The 100% water tight, positive air pressure is amazing!

Thanks

Very nice work! I can´t see any water pump in your system or doesn´t it needed?

Regards,

Pablo

If you think the branches may be prickly, you can file them down. The remaining volume would still allow them to be manageable (screw/unscrew). Not sure it would create some anodization issue.

It doesnt need a water pump. 5x8 tube running from the front of the motor fairing has enough

water pressure to do the job.

Maybe the photos make them look bigger than they are. They are a non-issue in regards to safety and I have never felt them getting on the board. Of all the edges and rotating parts on an efoil to worry about, I’m amused that these would get a mention.

Hey @michion, I was looking at doing my gasket on my new board with mold star. I was going to use EPDM to make the gasket to pour the mold star in, but I did a small test and the mold start didn’t cure next to the EPDM . I though there was something on sulfur causing that issue, but I can’t see to find mention about that now. How did you do the wall for the gasket pour?

I’ve been doing several of these lately. Make sure to clean the surface thoroughly with acetone before the pour. I found XPS (smooth pink panther foam), MDF (with a layer of epoxy), fiberglass, carbon fiber all to work well as surfaces to pour against.

Also note that high humidity has an adverse effect on the curing. Vaseline works as a release agent, but definitely causes problems in the curing.

100% silicone will stick to the Mold Star 30 and bond it to another surface, but not as well as the adhesive designed by Smooth-on.

Patience, degassing, level surfaces…

All that said, I’m curious which foam @michion used for his barrier.

Yeah was thinking of cncing wood/mdf/foam wall, but that seems like a lot more work then weatherstripping. And also took the CNC apart again to make it “better”  so I need a couple evenings to get it cutting again. (was going to cut some aluminum for a esc box)

so I need a couple evenings to get it cutting again. (was going to cut some aluminum for a esc box)

Humidity shouldn’t be a problem right now, thermostat says about 29% humidity inside right now.

Got a degas pot ready to go. Hopefully the amount of mold star should be enough to do the whole seal.

What CNC you running?

A brycej deluxe special

Rebuilt redesigned about 3 times over that last 10 years. Had used cncrouterparts(avidcnc) older parts. But now switched to linear rails and ballscrews. But probably shares some ideas with what they have done in the last few years. Cuts around 4.5 x 6 feet. Working on making everything more rigid now.

Anything containing sulpher will retard the cure on platinum silicones.

Have a read of the product guide that came with it, its all in there.

I used a white window sealing foam. I think its a PVC foam.

I generally stay away from any black foams or rubbers when using this stuff.

Please share which drill bits you are using to mill foam