Hi,

I’ve been reading here for a while and recently completed my first build. Creating this thread to document my progress and lessons learned.

My goal for this build was to build something simple similar to Foil Drive Assist that I can use with different boards.

I’ll probably mostly use it to catch waves/swell, but I also want to do a little bit of efoiling.

For efoiling, I’m using an Axis mast with the motor mounted closer to the fuselage. The motor cables are routed inside the mast.

For catching swell, I’m planning to use my Lift mast and mount the motor close to the board (like Foil Drive Assist).

Here are the specs of my current setup:

- Controller: Flipsky 75100

- Battery: 10s2p (42V, ~300Wh, P42A cells)

- Motor: 6384 150KV (I also have a 120KV version which I haven’t tested yet)

Here is the full parts list: Parts list for DIY Foil Drive with 10s battery - Thomas - Google Sheets

Here is my mast setup for efoiling:

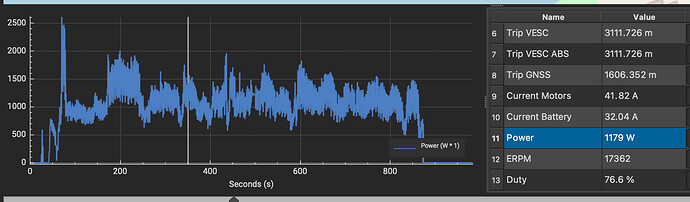

I was surprised that the motor is powerful enough to ride a Lift 120HA front wing (~775cm surface area I think).

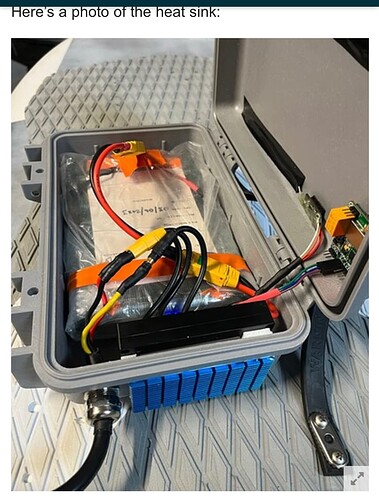

The photo above shows the 10s2p P42A battery inside the plastic box. With a bit of padding it fits almost perfectly. The box I’m using would be high enough to fit two of these batteries with the VESC on top.

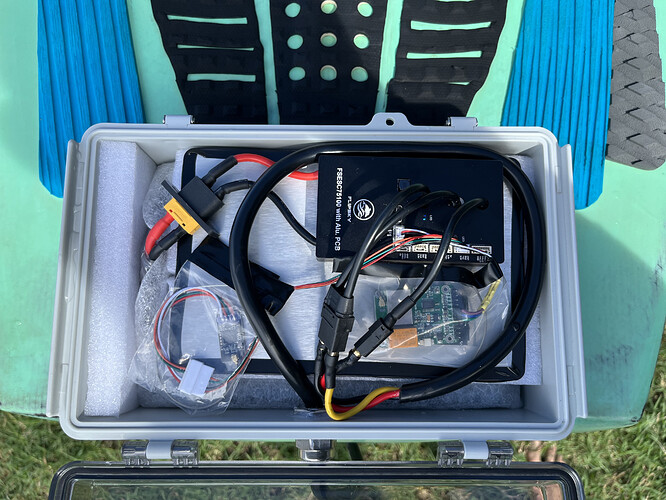

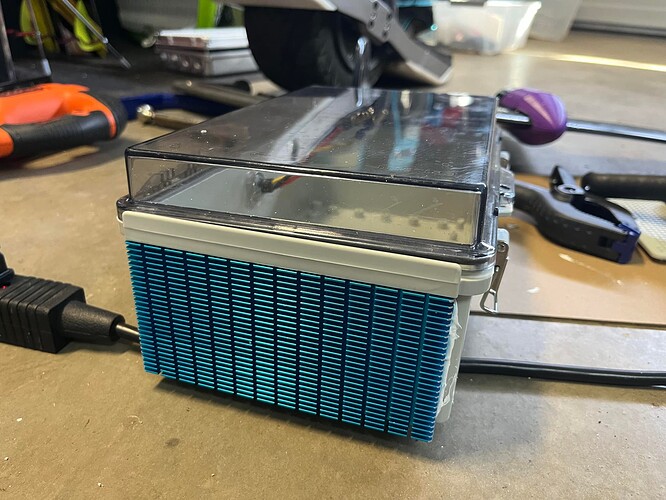

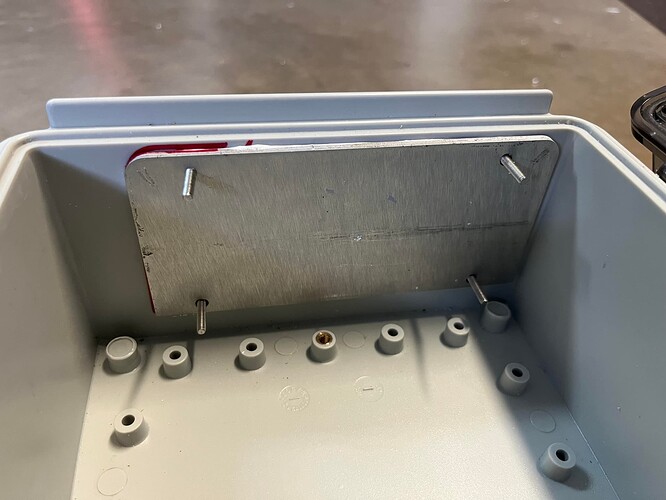

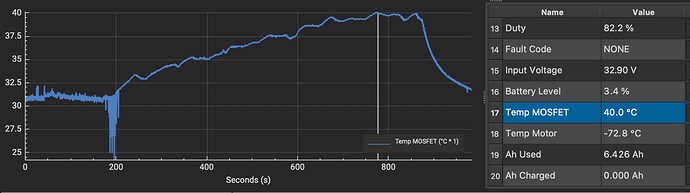

The photo below shows the VESC mounted on an aluminum plate (heat sink). I need to find a better solution for getting rid of the heat, because right now I can only ride for about 4-5 minutes before the VESC gets too hot and I need to take a break. I’ll probably have to cut a hole into the box and install a proper heat sink on the outside.

Below is a closer look at the current setup. The plastic box is mounted to the board with 3M dual lock (no issues so far). The cable setup in the box is still pretty messy, but I’m working on cleaning it up.

I replaced the motor bearings with stainless steel (thanks @Thaiguy for the info on what to buy) and soaked everything in CorrosionX. Hopefully that will keep it working for a while.

That’s it for now. I’ll update this thread when I make any improvements. Would appreciate any tips on how to improve this setup (especially the heat issue).

Special thanks to @Thaiguy, @3rd_ave_Lien, @dmitrynizh, Rick and all others who helped me with this build.

I am increasingly more convinced that it is the right thing to do.

I am increasingly more convinced that it is the right thing to do.