So a flat bottom wing tend to better for hydrofoils ? I’ll do more research and try to make better wings! You could run into some problems if you import the CSV file but it will be more precise for sure. You can use splines and try to be as precise as possible (don’t expect too much precision from the 3d printer anyway).

I tried to use 3d printed honeycomb material on this fiberglass wing. It definitely increased stiffness! The joining process is different and stronger too so the wing is lighter (it weighs about 930 grams so you save about 250 grams - 300 grams of weight).

Not sure about the painting tho lol maybe I should make it black and white or just plain white.

Adding the honeycomb structure helps a lot for fiberglass wings (I removed one backing layer of fiberglass because it already had enough strength).

The files are update! I guess you could use a similar method to make the fuselage&mast hollow but I would not recommend it (better to make a mast as strong as possible to make it as safe as possible). Also this wing cost almost nothing to build (around 25$) because the same materials are being used. I will try to improve the method for the mast&fuselage too (to make it stronger, lighter and also easier to build).

The more a profile is curved, the more it translates small variations of AoA into strong lift changes. Therefore many brands choose to have low to zero curve to have a more controllable foil that doesn’t breach the surface too easily at high speed because breaching often means falling.

A friend told me that the Taaroa Noe 2020, a high AR freerace windfoil, uses the S7055 airfoil section or something very similar.

Manufacturer description:

A extremely rigid and stable foil optimized for power and speed. For riders who look for performance with serenity.

a little bit of topic, but still 3D and CF related.

I’m thinking of 3D printing some parts for my jet board (with PLA), and I would like to “wrap/cover” them with CF (maybe 2 layers?)

Question. Does CF when curing get hot, and will it destroy the 3D PLA created shape?

Thank you for any info on this.

It’s no Problem with Epoxy.

Greetings Frank

Yes that’s right, you will get more difference of lift for the same variation of angle of attack. I analyzed 3 profiles (RG15, E817 and AQUILA 9.3%). I preferred to choose known profiles that have already been used. I wanted to create a wing that can provide enough lift at low speed (and at a “higher” angle of attack), but also to be able to go faster if we want to (at low angle of attack). The AQUILA 9.3% is great too (very similar to the S7055) but I couldn’t find a better wing shape (delta shaped) with a good AR and surface area that creates enough lift at low speed (and higher AoA) and not too much lift at higher speed and low AoA (to go faster).

But I was planning to test each wing myself to be 100% sure even if any wing works. It would be nice to optimize it to make nice and easy to use.

If it’s only 2 layers the epoxy will not release enough heat to soften the 3d printed part. If you try to make a super thick (+5mm) part at once (and you use a fast hardener) then yes it will be most likely too hot . Do you know which CF cloth you will use ?

I am thinking of using 245 g/m² CF cloth (link to Dutch website: https://bit.ly/3i7LQKD )

Thickness 0,393 mm

What about 90 degree corners? Will this work, or do the corners need to be rounded (like for glass fiber)?

The rubber gasket groove will be 3 mm deep and 90 degree corners at the top of the groove.

I will be using a vacuum bag!

If you want the CF cloth to be in contact against the surface then yes it needs to be rounded. Usually you need at least a minimum of 3mm (or 1/8’’) corner radius. The part seems very small, you may have a hard time warping it with CF!

Yes this part is small. It is for the rubber sealing (gasket).

I’m going to leave it as is (PLA), and maybe just put some hardener on it.

Anyway. Thank you for the information. I’m 3D printing the needed parts now. It’s going to take a long time…

Hi I have problems with the operation to access the course. The link is corrupt

https://easy3dcomposites.thinkific.com/users/sign_in

I tried to open a helpdesk, I wanted to find out if any of you have the same problem.

Could you give me a hand to unlock it?

Thank you

any reports on how well the foil flys?

Hi Kian,

sorry for the question…

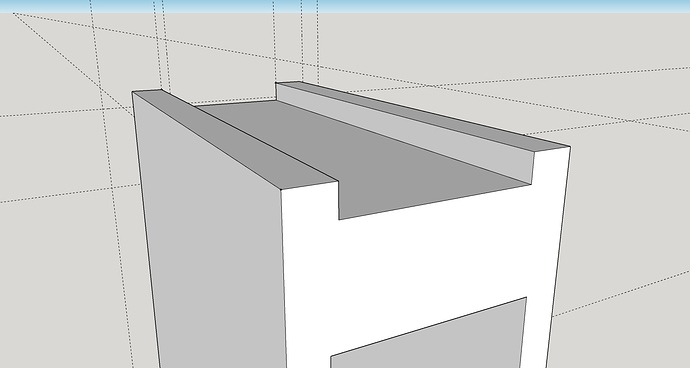

If I understand from your picture, do you use SketchUp for design your board/wings please ?

Thanks a lot

Denis

Thanks a lot ![]()

I’ll read all courses in order to understand if I’m capable to make all this by my self.

Thanks again

Denis

We used SketchUp for designing the battery / ESC’s box for our jetboard

Oh

I just think maybe you have a board SketchUp for a eFoil

I know use it but I can’t find some model to start from.

Thanks a lot for the answer.

Denis

Have you finish the board project please ?

Thanks for all documentation

Denis

Can I get the Stl files?