Sure, will let you know after we have this kind of service. Thanks for attention on E-ark Tech

We are able to do that, but normally manufacturers like this do not know English.

(Build from Moscow! - #360 by Anatoly)

This is just one of all the other examples of a forum member buying a relatively expensive motor (Flipsky 65161) and the propeller offered with it (suitable at best for a small fishing boat on the calm surface of a small pond:-). He subsequently finds he can’t use it, so he either puts it away or has to go through the sophisticated process of reducing the diameter of the blades by grinding them down. However, such a trimming process is always trial and error. As a result, sooner or later he has to buy a new propeller. And since his budget is also reduced, his first choice is this propeller https://www.custommotorsfrance.com/product/propeller-complete/ It is a propeller that is not only one of the six favorites (as I explain above), but originally designed to power the Fliteboard e-foil, which is considered the best in the world.

understand, thanks for sharing the information with us.

Glad to let you know that we re-sell HGLTECH products now,too. We have flash sales for 65162 motors now within 48 hours.Pls check the link below for more details:

https://earktech.aliexpress.com/store/group/HGLTECH/911717331_10000001629048.html?spm=a2g0o.detail.0.0.6d6278e878Qe2F

You guys could let us know what products you would like to order from E-Ark Tech, we will try to upload more hgltech products and offer flash sales for all you needed. Welcome to leave comment below.

(How would you trim down this metal prop?)

So the topic is about the same propeller that you are offering today (8 June 2021) on your e-shop and claiming that this propeller is an accessory “for Efol”.

It’s unbelievable, the topic “How would you trim down this metal prop?” was already created almost three years ago (November 10, 2018) and to this day not a single Chinese propeller manufacturer has shown interest to start producing the correct performance type propeller.

We are interested in your proposal. Could you pls kindly check your private message, we can talk more there.

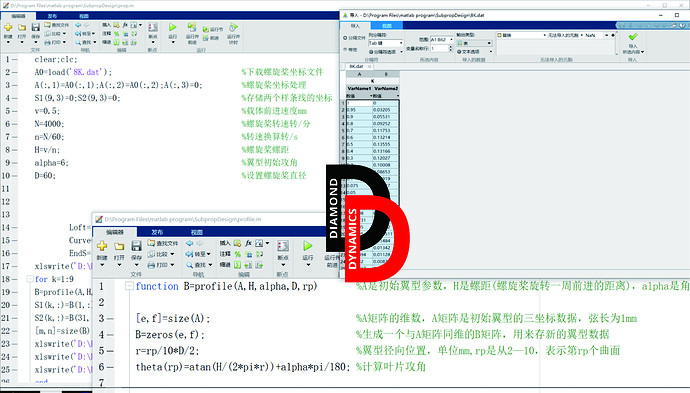

We can make propellers, and we can customize propellers for customers. We have a set of program codes for automatically generating propellers (of course, this code algorithm is verified by a lot of experiments). We can make the propellers you want according to the parameter requirements you provide. .

Diamond Dinamics, do you have also complete set to buy ?

Hi Gianvi

We develop and produce thrusters. We can also customize thrusters or motors with different thrusts for customers according to different needs. We are a professional manufacturer of motors and thrusters.

541xx is not powerfull enough as direct drive on efoil.

There are more powerful, 46KG thrust.

V1.2 version will be shipped, or you can let you know your requirment. Thanks.

Thnx, just ordered one.

Thanks for your support, we will upload tracking number after the package is shipped.

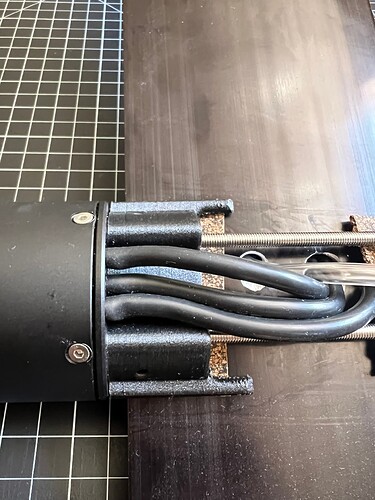

I bought two 65161 motors from E-ARK over a year ago. Just getting my build to the finish line now. After mounting one of the motors I noticed that the motor mount has slight decouping. The outer housing of motor has very small amount of WOBBLE to its frame. I notice this wobble when lightly applying hand pressure to test for strong mechanical coupling to my mast mount.

The holes around the base are clearly warped. Very upset because I just noticed this. Anyone else see this issue? What is the fix?

E-ARK, Fritz you give good solution?

Seen this on flipsky motors too, the material thickness around the screw towards the edge is too thin, especially if the screw has worked itself loose and has allowed some movement.

It’s easily solved by making a few new threaded screw holes if you know how to do it.

@EarkTech: this can be fixed easily by the design of the motor. If the screws/ end cap works itself loose then motor starts leaking and is ruined - it is a serious problem.

Move the holes in the motor shell 1mm, make the end cap 1mm wider, add one or two extra screws around the perimeter of the shell.

It will add a small cost for material and labour but the issues will be solved.

Thanks for your comments. I know how to tap threads but don’t know where to safety tap on the motor or how deep to tap plus any other considerations to bear in mind to ensure waterproof. I created a new thread to track this issue please post replies there. Cheers!