Thanks for sharing. Have you tried the maximum speeds of the two propellers? Is the pitch of the fliteboard propeller also 7 inches?

Today, the new 3D printed nylon two-blade propeller was tested, and the overall feeling was relatively stable, but the power was a little weaker than the three-blade propeller used before. The pitch of both propellers is 7 inches. I wonder if it would be better to use a 9-inch pitch. The propeller broke a little after one use, and the 3D printing was still not strong enough.

Interesting, that looks like an MJF print just like my copy, so it should have been pretty tough. Did it contact the duct housing? It chipped both blades.

How did you find the noise level? For me it seemed like a trade off losing some power and responsiveness for peace and quiet.

Anyone interested in max efficiency? I’ve wondered what max efficiency would look like, though it would require an assist to get on foil Foil pumping using low power efoil - #9 by mterea

Hello guys!

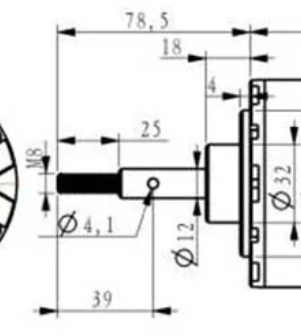

@JvdZ I am really interested by the design of your 143mm diameter propeller! Can you change easily the pitch (max 152.4mm / 6inches) and pin (diameter on the photo below is 4,1) ? I would like to fit your propeller on my motor (Maytech MTI85165)

Thanks!

@Flo98 I don’t have the software anymore to modify the original files. The pitch of the blades is locked in the design, not a variable.

The prop might be a bit to small for a big motor unless you are running high RPM. I currently flying with a flying rodeo prop or fliteboard prop. The fliteboard prop is about 50eur, very good prop but you need to enlarge the bore to 12mm.

@JvdZ The motor is 200Kv, that’s why i am trying to find a low pitch propeller because i draw too much current and thus my VESC overheats. The propeller i have is apparently an (old) fliteboard one. What pitch is yours? Trying to find or 3d print a propeller with 143mm diameter and low pitch (under 6 inches)

The diameter of the propeller can currently not exceed 143mm otherwise the blade would hit the fuselage, but i could design a 3d part between the mast and fuselage to lower it. But larger propeller means more drag and thus higher current?

What was the software you used to modifiy the original files?

Aha, I understand the low torque application. Files came from a very early version of SolidWorks, 2011 I think. Modelled the ugly way with splines/crossections to form the blade geometry… So no parametric pitch adjustments.

@Flo98 You can ask @superlefax = (https://propellerking.com) if he has a 3-4” pitch prop to offer. I think his props are 3d-printed so might be possible to get something even though it’s not on the site, if there is a design already tested.

that would be great, i will send him a pm!![]()

-

For the diameter, should i stay at 143mm or go larger? (more current is needed for larger propeller?)

-

For the pitch, you think 3-4"? I was advised some time ago FR, EML or Easy Foil 6” pitch. But these propellers are more than 143mm diameter

Otherwise i just started to use Pacificmeister parametric propeller but i am getting fusion error when i try to change ductGap (to change diameter of the blades) and not sure also how to change the pitch

one solution i see now is to use this 5’’ pitch duct and i have to cut it to reduce diameter to 143mm:

3-4” assumption comes from that the most of us run 6-8” with 120kV motors.

Scale pitch with kV:

6x120/200=3.6

8x120/200=4.8

Your esc would probably be happier in the lower span of this, but 5” could be worth trying.

You don’t want a larger prop since that has a double effect on increased current. Flipsky prop needs to be cut down to roughly what you use today or less

@Larsb … please excuse my ignorance on prop design but what does that calculation illustrate?

Interested to know for my own lack of knowledge on tbe dark arts of prop design🤔

No dark arts, only estimations and some physics behind. The numbers below are examples of what is working setups to compare against, not laws but they serve their purpose in this calc.

The flite prop (from memory) has about 7” pitch, gets you to roughly 120x44x7x0.0254x60x0.85, about 48kph with a common 12s 120kV setup. You don’t need much more ![]()

Flo has issues with overheating the vesc, the current needed to create torque with his 200kV motor is (at least part of) the issues.

On a 120kV motor about 100-150A is needed to get up with good setups, let’s take 100A as an example, this is about 8Nm of torque, to get same torque on a 200kV motor you need 200/120*100A=170A

Resistive heating increases by the square of current, the relative losses are then 170^2/100^2=2.9 - so it’s close to 3x higher heating

It’s easy to see that esc heating increases and could cause issues. Lowering the load on the motor is one possibility to decrease the heating, a prop of the same area and diameter but different pitch will achieve this (or a smaller one).

The torque to drive the propeller is proportional to pitch, and therefore a propeller pitch scaled with kV (7x120/200=4.2) would lower the current back down to 100A (but with a higher rpm to get same speed and power)

This calculation has a lot of assumptions, not 100% correct also since propeller efficiency seems to peak around pitch/dia=1

(i don’t know why really) so a 4.2” pitch / 6” dia propeller will probably have a bit lower efficiency - but can help with the esc heating.

thanks for this detailed explanation @Larsb !!

I actually found today and ordered a 4.2 pitch propeller with 150mm diameter

Where do you find the pitch of this prop?

I contacted Maytech today, according to them it’s 4.2 pitch

I hope they are right

Indeed I got two low pitch pink lady’s at home with 4" but they fit to an outrunner motor (6374/6384). I use them on my 20km/h Turbo SUP.

these pink ones are from Maytech? What voltage and Kv do you have to reach 20km/h?

@Larsb i will probably stay up flying after takeoff without overheating, with such a pitch reduction from my flite prop (old fliteboard design, probably 7’‘) to 4.2’'. But I will already be at a high RPM and may not have a lot of RPMs left to go faster… I was hoping to reach something like 30kph

Can I think like:

I was taking off at 3250 rpm, so I will now take off at 3250 rpm x (7’’ / 4.2") = 5416 RPM. My motor can actually run up to around 8000 rpm (tested without load), so actually i have 2500 RPMs left…

Sure, but you should be able to reach 10krpm. If you only reach 8000 at full voltage then there’s probably a limitation in your esc settings.

Just a note, at these high rpms there could be risks for magnets exploding and high eddy current heating. I don’t know what the rpm limit for your motor is. You better check this.