Thanks to share the link. Need a cup of coffe to read quietly.

Regards,

Pablo

I have seen that and looking for that too, but no luck. Maybe a custom T nut with some drills on flange bottom for glue.

Regards,

Pablo

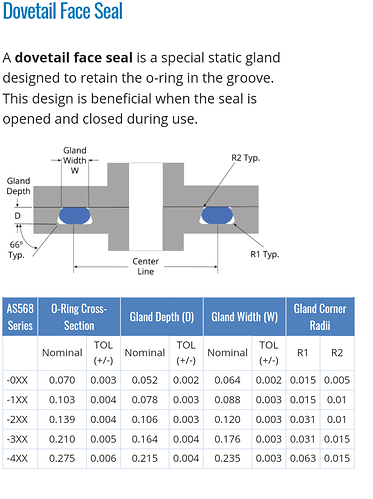

Trying to seal mast plate with silicone oring. I will show my result very soon.

https://www.amazon.es/Sourcingmap-silicona-diámetro-exterior-145mmx3-1mm/dp/B07CVFT8GC/ref=sr_1_44?__mk_es_ES=ÅMÅŽÕÑ&dchild=1&keywords=junta%2Bde%2Bsilicona%2Btorica&qid=1602612341&sr=8-44&th=1

I am really happy with mast seal. It works well! Also I found the problem on the lid seal. i will try Manu´s solution.

Regards,

Pablo

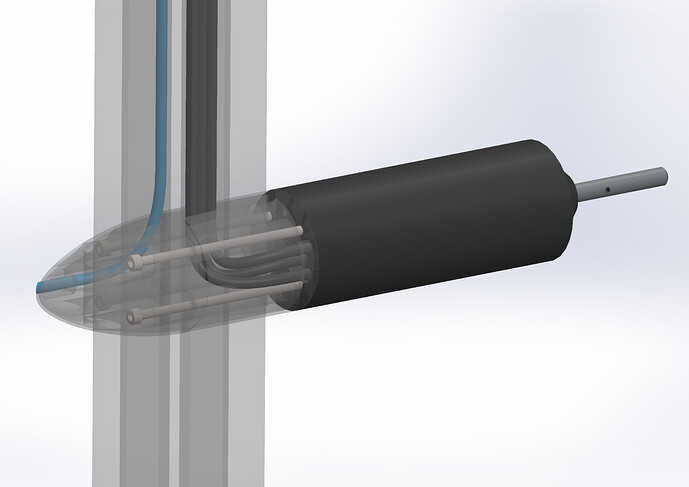

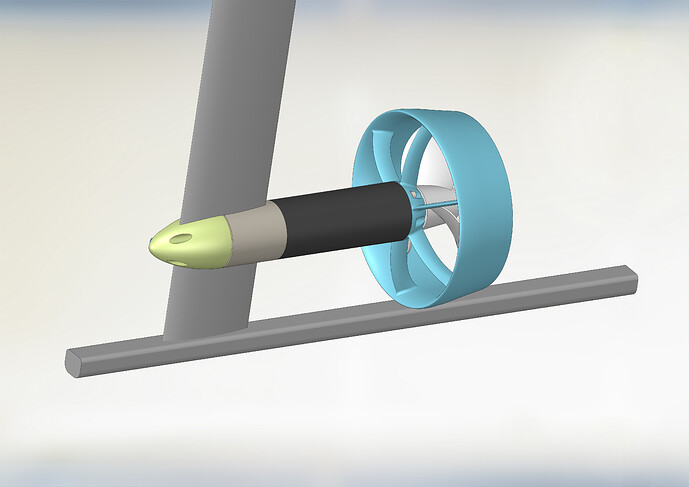

Hi, looks like great progress. Will you be 3D printing the motor mount?

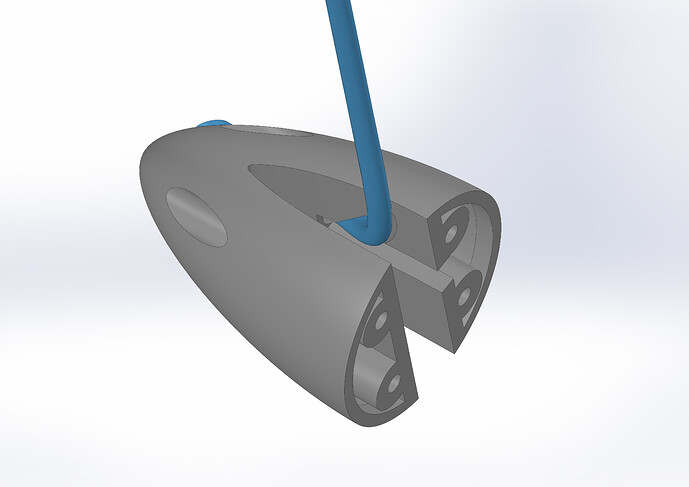

Sure. I have to make some tweak on this.

Looks like the gong mast. From my experience I can tell you that mounting the wires and tube with this kind of motor mount is a pita.

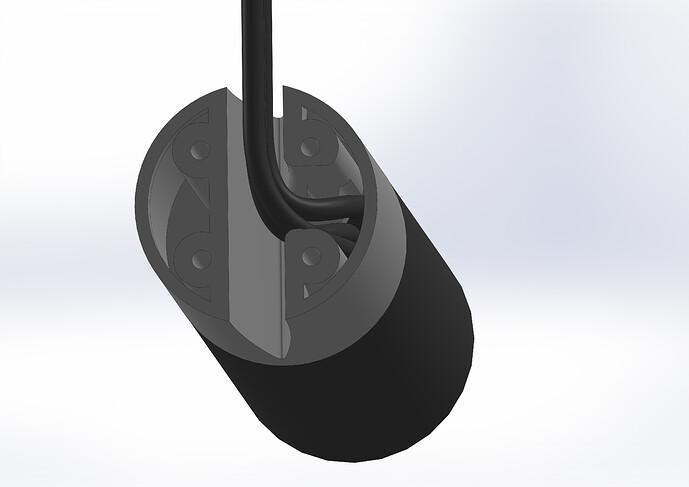

I did like this.

The wohle cover is just slide on and clipsed in position.

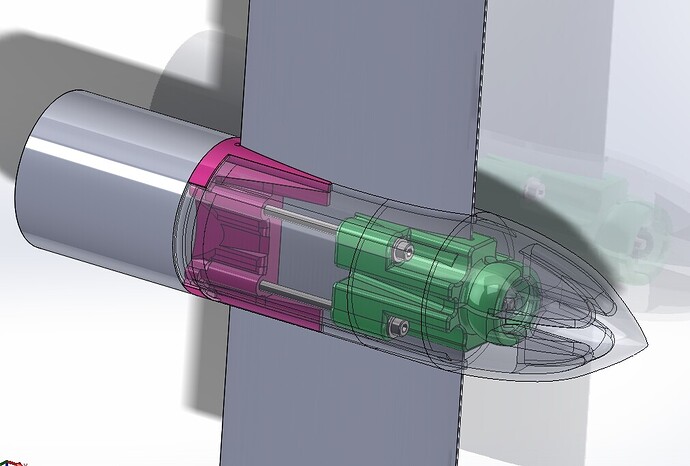

Just to give you some other ideas befor you start printing

i like this idea, it is what I had in mind, although you have already though about it, apparently.

I have PETG and TPU - I have printed clamps for 25mm carbon fiber tube before - in tension, TPU is very strong. I undersized the part, and use the screw to increase the tension, providing the clamping force. What are your thoughts of PETG vs TPU for this application? In your picture above, I would print “Purple” colored part from PETG, while “green” from TPU.

I printed all parts in ABS. Works nice.

Did you post the Fusion 360 or STL files on another post? I think this would be a nicer setup than what I currently have. I use a Naish mast so I would have to modify it but I’ve got plenty of time this winter.

I can send you the stl files. But this is for a 63100 motor, and has no opening for a cooling inlet, as I am running passive cooling.

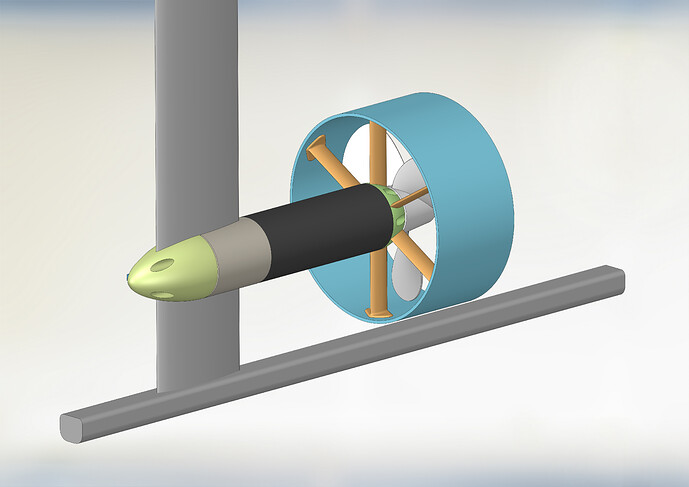

Nice pod printed!

https://www.dropbox.com/sh/ks4tggmqlkbfsfx/AAAS2BLVckABF-tOJljqey1fa?dl=0

https://es.aliexpress.com/item/4000201563695.html?spm=a2g0o.productlist.0.0.554030c8DqjaiU&algo_pvid=b380faf0-609f-4158-adeb-2228eaf1b879&algo_expid=b380faf0-609f-4158-adeb-2228eaf1b879-30&btsid=0b0a01f816028130132924422e869a&ws_ab_test=searchweb0_0,searchweb201602_,searchweb201603_

Regards,

Pablo

Hi, that is great to hear. I have some ABS as well, but sometimes struggle with the warping and shrinking, even with heated chamber. Usually have to scale the parts 101.6%!!

Hi Toto44,

Could you share your clamp stl files, please. I am using 63100 too, but on Cabrinha mast. I think your type of clamp can fit different profiles with minimum modifications.

give me your email and I will send you the files.

eug_sm@yahoo.ca Thank you.

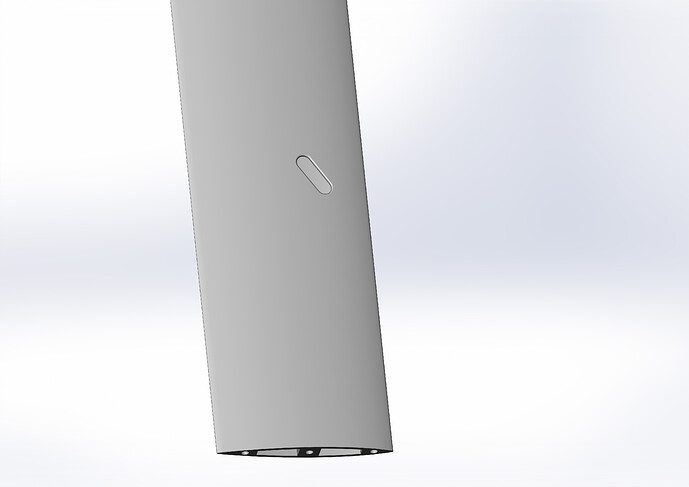

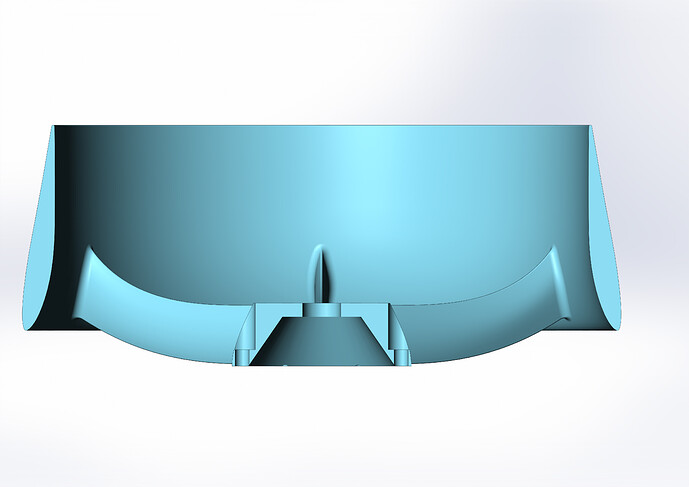

Version 2 with Eppler E207

https://www.dropbox.com/sh/m6j1zpcjgt3uvcz/AAC5qsP-hKSEGgJ2SIiMBZlMa?dl=0

. Some drops inside. Need to change mast plate seal.

. Some drops inside. Need to change mast plate seal.