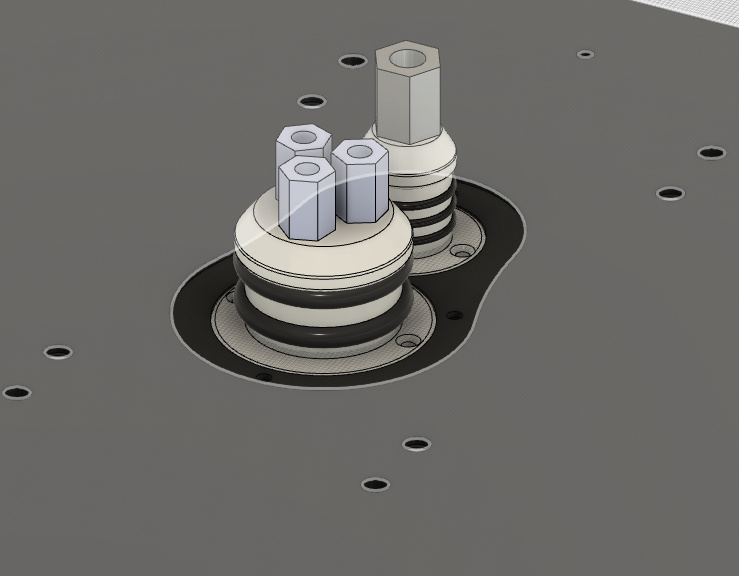

first assembly…

Looking good!!

I’m planning to 3D print my box too and wrap it with carbon.

Questions:

- What infill setting of the 3D printed parts did you use?

- It looks like you did not put any carbon on the top part of the 3D printed box part (where the seal is). Did you cover that part with only epoxy?

Any info on this will be appreciated.

I print with 25% Infill.

On the bottom side I glued and screwed the Aluplate with an special Epoxy glue.

On the top side I use a special plastic spay to waterproof the printed parts.

When I screw all together, I will put 2 layers leal between.

25% infill… Hmmm I’m now printing with 5% :-/

My printer can only handel 20x20x20, so I need to print it in 4 runs.

The 1st part needed +30 meters of filament for the 1st part when set to 20 % infill.

Anyway. I thought that 5% t would be enough as it will be covered with CF.

2 more hours to go, and the 1st 3D part will be done. I’m going to do a small test on this and see how it will end up.

I am also planning to glue the bottom aluminium plate to the PLA.

Spraying the top part with waterproof plastic sounds good. What pray are you using? Do you have a link to the product for me?

Thank you.

nice work!!

why did you changed the APS 63100 motor and went with Flipsky 120kV, because it is waterproof?

I often was asking about the STL from my Mastclamps:

Here again:

Front: Microsoft OneDrive - Access files anywhere. Create docs with free Office Online.

Back: Microsoft OneDrive - Access files anywhere. Create docs with free Office Online.

Today I screwed all together and drove to the lake and make my first water test.

What should I say, water is coming inside both areas.

Now I must start searching from where…

Very nice , for the leak , I would use a screw hole from the access round trappe to put a hollow screw and pressure the box under water ( like a pump bike or else …)

The Problem is, no screw is going inside

Well you can always find on way to pressure the inside : mentos in a cup of soda  …

…

Or do the other way around , water in the inside …

Hows the alu plate sealed to the tub?

I got this far with my 3D printed / epoxy parts. I gave up.

I screwed theme and glued theme with Uhu plus endfest

Where do you suspect the water might be coming in?

I don’t know. I will glue it now inside with Epoxy and Microbaloons and perhaps plus Silikon after.

When it not help, I will think about a Layer Glas or CFK over laminate.

Shoo Goo is the glue you need!

i have send you pm…

Great solution!

Could you share 3D files for printing?

witch one you want?

…

Thank you nice2cu ![]()

I ment this from YAHEF https://efoil.builders/uploads/default/optimized/2X/1/19346b736004b7287a406fb34ba13f106d33ba15_2_562x750.jpeg

I think for this rounded one would be easier to make an inflatable board.

But yours duct and prop 3D files would be more than wellcome too ![]()