Could you post a picture of the prop failures, I’m interested in where the weak points are?

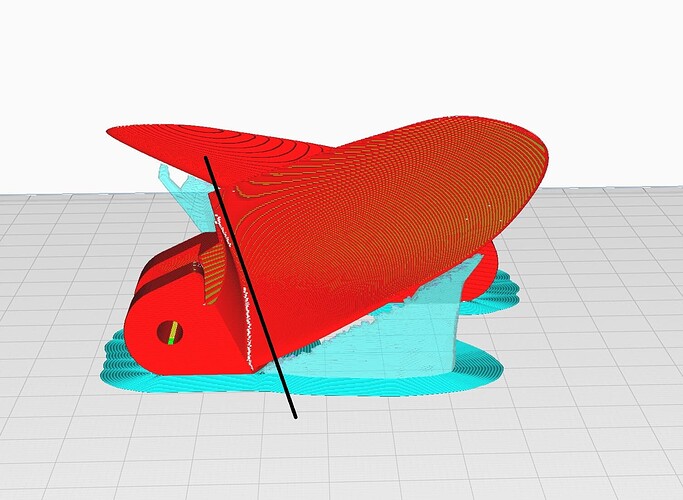

I dont have a Picture right now. But It Cracks always on the edge of the folding mechanism to the wing. Marked with the Black line:

So my investigations about the failure mechanism are right now:

The opening shock when turn up fast (Current controlled VESC) is way to hard.

I Already tried to make it with 100% Infill, it makes it even worse. Because the opening shock on a stiff part is even more stress for the material.

So the my current work is to develop a 2 phase opening of the Prop. Version 4.1 becomes a TPU printed dampening system to reduce the opening shock massively. I already did some dry tests. and it seems to work: https://youtu.be/szalWEe53GM

take a look to the gap between the base and the blades. Initially the Blades crash against the TPU dampers. And then at full speed/ Watertrust the blades going to press the dampers together and unfold completely. I am going to make now some Watertests and when the system survives some hours. you get the files for mass testing ![]()

Btw. I got it to print without any support ![]() : https://youtu.be/T9G5VNzGN-U

: https://youtu.be/T9G5VNzGN-U

I’m going to try PLA-ST as it is supposed to be 10x as impact tough, compared to PETG or PLA.

A dampening block seems a great idea, with some sort of high density polymer.

Printed the prop with an sla resin and have had no issues in 6 hours of use in the surf.

Does your ESC regulate on rpm or on current.

→ mine is on current and thats pretty stupid when i start thinking about it. Because the acceleration and the opening shock is pretty hard.

My esc regulates off RPM no current. I try to ease into the throttle to go easy on the propeller opening.

Is it a VESC, and if so which settings are you using for a soft start?

Vesc user , you can choose to run duty or current mode , you can set the slope of the throttle curve , you can play on the ramping time to add some delay to smooth thing … you can do a lot …

But no there is not a smooth start option in that case , you need to adjust thing in condition ( speed …)

You can only smooth the throttle by adding some play and or time , and my guess is that you will have more control over this on duty control ( rpm) vs current mode ( torque)

We will need a 3D mapping including rpm/current/throttle …

How reliable has the tomiboiesk8 ESC proven so far? Do you know if it will be safe to use it with 13s?

Til now i dont had any problems with it. 13S also works perfect for me.

The only thing i am a bit confused about is the high Temperature.

It still reaches 65°C in an ambient temperature of <10°C with the giant cooler. So i am wondering if this still works in an warmer Ambient temperature ![]() .

.

I have now 2 watertight boxes. The current one for 48V Liion packs. And a new much smaller one for 36V Liion packs. I gona add some picture of these later.

Here is a Video with the small box: Michi on Instagram: "Hydrofoil pulled by a rowboat? Would it be possible 🤔. Had this genious ideas while gliding along the Neckar. Beside the young machines of @rudervereinesslingen. Their speed would be enough 🚀👍. What do you think? Bigger boat with more people? Cheating for the start to get on foil? In this Video i am just following with my diy efoil to have a nice talk. But if any club is willing to try it i am in 👍. . . . . #rudern #diyefoil #foiling #rowing #rowingboat #rowingmachine #efoiling #ruderboot #neckarfoil #neckar #watersports #watersport #flyoverwater #swabianefoil @tuebinger_rv @stuttgarter_rudergesellschaft @ulmerruderclub"

And Here a Video with the big Box: Michi on Instagram: "Its wet and cold outside. So perfect time to go efoiling 😍. Beside a lot of family lunchs and amazing talks. A amazing way to relaxe and enjoy nature by flying over a quite and foggy river in the morning hours. . . . . . #diyefoil #gonggalaxy #foiling #foilsession #riverfoiling #efoil #efoiling #efoilinglife #overwater #winterwaterfun #flyabovewater #eboat #eboats #swabianefoil"

To switch the Boxes i use a watertight 3 pole plug outside of the box. This works great till now.

My 8364 got also the final bearing update. Like some others i am using the BB6800B18030GL and BB6900B18030GL from Igus for the radial bearing. But i used a H370FM101207 Plain bearing for the thrusterbearing. With a polished and reamered Steelwasher on the rotor side.

All my delta measurements till now show no measurable difference in powerconsumtion!

It works perfectly!

I also made several new Tests with the folding prop. But even the SLA parts could not resist the opening shock of the current regulated start. So i propably gonna try out a much stronger material.

The temperature of the vesc doesn’t sound ideal. I’ll be running continuous 20-30A in 30 deg C ambient. The makerx 75 / 300 vesc I’m using at the moment seems to get to about 70+ degrees, with only passive cooling inside the pelican.

How watertight is your heatsink on the outside (also on Alexandre’s build)?

Did you change the vesc to run with rpm control, rather than current, to save the props?

The Heatsinks are perfectly waterproof with all the silicone.

The rpm controll is probably the only way to go. Manufacturing is way to expensive. But with rpm the opening is not as good as with current control  .

.

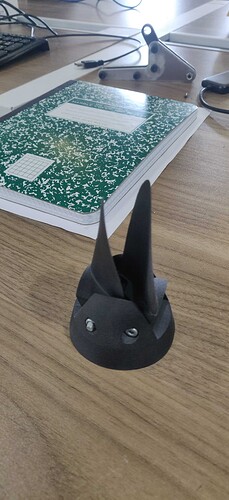

Got finaly a new working version of the Folding Prop. I tried a lot of different things. Here is the final changelog:

- completly redesigned the blades to reduce mechanical weakpoints

- also finetuned the tolerances to reduce sanding to ~1 minute

- added a TPU 95A damping system

- raised the printing temerature of PETG to 250°C for better layer adhesion

- printed with 0.1 layers, 4mm walls and 40% cubic infill. No Support for the Blades with dual blowersystems

- after sanding everything i mount the blades in the base and paint a thin layer of 5 min Epoxy on the blades (every part that gets not in contact with the base)

- then sanded down the blades just a little bit to get a better surface.

- Set my VESC to current controll with 4s delay in powerup.

This works just amazing for me till now. Its completly reliable for 4-5h till now.

Lets see how long this lasts but looks promising.

Here are the Files:

PETG: http://kitegruppe.de/downloads/KlapppropV4.2.STL

PETG: http://kitegruppe.de/downloads/BaseV4.2.STL

TPU95: http://kitegruppe.de/downloads/Daempfer.STL

I am curious how it works for you.

Can you show the orientation of the printing please? No supports?

Scott

Scroll up in the thread…

Orientation ist like this: Swabian Efoil build - #15 by Jatem

But no Support needed if you have a good blower from 2 sides on your printer head.

Thank you for the great prop design. I will print one in Fuse1 SLS Nylon for my build.

I find by google that page and love your design of the prop a lot. I was thinking about buying a Foildrive to add it to my Levitaz HA1600Pro foil and 100L Wingboard.

But the unhydrodynamic Prop is what keeps me off.

Does your Prop fit to foildrive?

I don´t want to build everything by by self and prefer to get it at least a bit plug and play.

Thank you, Armin

Hi Armin,

from my point of view it should mechanicaly fit. But i am not sure if the blades are big enough for the rpm. As i understood they use the same Motor but with a much lower Voltage. The Prop blade design is kind of the most important thing when it comes to efficiancy!

There is a thread where people try to build foildrives on theyr own: Foil Drive Assist, DIY - #330 by Pod

I think they should know if it really works…