Lift released version 3 and seems they are going to release soon an Elite 3 version with carbon prop… anyone seen it? Always thought it was the way to go for best performance. Petrol jetsurf has a really thin carbon impeller.

Maybe a carbon propeller is cheaper to produce than an FR propeller made of aluminum alloy (CNC machining + anodizing). However, it is always the case that the most important thing about a propeller is the shape of the blades, the number of blades and the shape of the hub, depending on the performance type of prop. Only second is the material used.

I don’t think a carbon prop will be cheaper than an aluminium prop. More labour, most likely will have to be prepreg and probably high modulus. For small prop like the one we use blade thickness is super important. Carbon allow to keep blade stiff while thin.

I recently modelled a propeller with three removable blades in 3d CAD. The blades can be carbon laminate or high quality aluminum, the hub will be high quality aluminum. On this project it will soon be easy to see which blade material will be cheaper and which blade material will be stronger for bending.

Yep made removable carbone blade in hub before, I had better result molding carbon prop in one shot. Blades were breaking where they entered the hub, I had to use high modulus UD for it to work

It’s admirable that you were able to make that type of propeller.

I think it’s easier to make a wing out of carbon. Have you tried it yet? Or do you prefer to use a commercial wing now?

Sorry what do you mean by wing? a foil front wing or propeller blade?

It is quite easy to mold carbon prop blade as above but I found out if you really want a gain in performance it is hard to make them thin and strong enough with this technic, they tend to brake at the hub where they are inserted. That said I was using printed mold, I might give it another go and cut aluminium molds when the CNC machine is free. I think the trick is to increase the root thickness where it insert in the hub, like 3-4mm thick where it enter the hub down to 2mm at the blade.

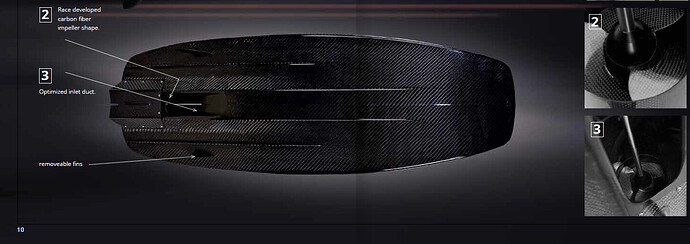

Jet surf impeller:

What have really been the improvement between the different Lift version E1 E2 and E3.

I read E1 and E2 25MPH, E3 30MPH

From what I undertand the motor is still the same. Would the speed increase come from using a 7" prop on the E3 while E1 and E2 was 6"?

Just for reference, the FR prop has a 5mm root and is 1.75mm at the blade tips.

Yes, I mean the foil front wing. Thanks

Yes I made quite a few foil full carbon.

In that case, I could advise or help you to increase efficiency.

I think, given the theory, that the speed will increase. But it’s very likely that the current will also increase (the battery will discharge sooner). In order to keep the battery from discharging sooner, the propeller efficiency has to increase, but that’s rocket science.

Supernova (announced to be back this July 2021) had a strong and original propeller blade principle for the torque model. Not sure it ever saw the light of the day. Has anybody ever seen this kind of aluminium extrusion ? Does it exist with 3 or 4 slots ?

These blades would be a bitch to mold if you want to keep fiber continuity up to the key sliding inside the extrusion…

A four-part mold: the bottom one in two parts opening along the female key and looking like the aluminium extrusion…

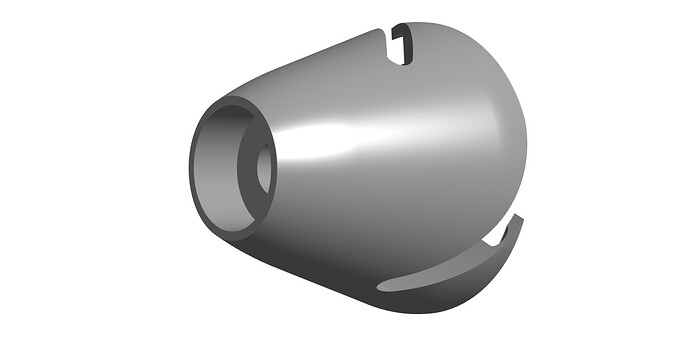

The blade hub (holder):

1- molded in 3D printed molds OR,

2 - custom extruded therefore costly because of small quantities.

The blade lock looks very clever, an aluminium blade would be easy to make.

I’ve been looking at a similar issue recently too - quick and easy replacement of a damaged blade, easy to make a carbon blade. Here’s a sample hub

The shape and size of the hub matches the Flite propeller, but the blades (which I can’t show yet) should easily outperform not only the Flite propeller blades in terms of hydrodynamics, but hopefully the FR propeller blades as well. I am now considering several issues, including whether to patent the blade locking system.

Well, this is a DIYS Forum and benefits from sharing experience and designs–sorry but I don’t see the point of announcing patents here. Post and contribute, OR patent it and keep it secret.

As I said, I can’t show the blades yet …because I am considering patenting the blade locking system. It logically follows that if the blades are or are not patented, only then (perhaps in two or three months) can I show the blades.

However, it is also true that the ability to replace a damaged blade is ideal for any e-foil owner, and many different blade attachment systems can be used. However, only one of them can be the best, so it is worth considering patenting it. I think my system is very simple, very robust and very cheap.