Yeah great starting job

Just a thing about the Big box down side of the board isn’t a good Idea because lot of drag for starting when you don’t fly on the foil …and drill 3 hole on the side of the mast when you Can fit it up of him under the board who you also drill lot of Space in the shape of the board…

Just good for cooling ESC … you can design hydrodynamics better for less ampli✌️

Thanks!

I’m still debating where to place the ESC. An alternative was like this:

(I think that what you suggest), so that the ESC gets cooled by the mast, and the water when starting up. But I am worried about the strength of the assembly.

In either case, I’m going to put a kind of “nose” around the whole mess in the hope to improve hydrodynamics.

Holes on the side are a request from my husband who is building the ESC. He’s also balking at the tiny aluminium box I have selected…

That was my thought. But many people say it’s not a good idea to have the box being a structural element. I might still do it though. That was my initial design, using a Polycase IP68 rated aluminium box ($16):

Hi Dan, thanks for the info. Are the plate and rails above ou under the board?

I used a router and insert them flush into the board and then laminate the carbon fibre on top.

I like your esc on top of the mast idea, I toyed with doing that but opted to put inside the hatch as it was to tricky to make everything fit.

Here’s what it looked like before and after.

You might get a better idea from here too

Thank you, it looks beautiful. I’m so envious and impatient to have mine! But it’s still a long way…

I saw that. It’s for 160V supply!

I missed that…

But I did see, Voltage 6-20S (25.2-84V)

Specs on this motor are all over the place… Internal parts quality varies from manufacturer to manufacturer, number of poles, type and strength of magnets, number of windings, wire sizes and purity of the copper, and on and on…

Yep, one spec I saw was 40S, I guess that’s how they get 16000 rpm!

Mounting the mast to the board

My board is an old F2 windsurfer (Power Glide II, 280 cm x 67 cm, 140 liters). My goal is to attach the foil mast to the board with the minimum amount of work and modifications on the board, for now.

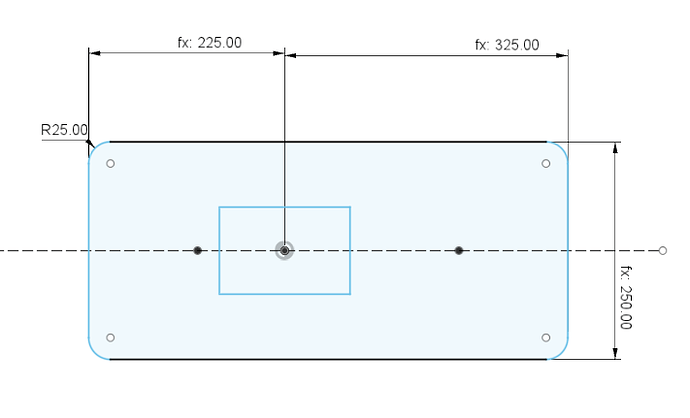

We’ve decided on the following setup:

- Epoxy an Aluminum plate under the board.

- Bolt the mast head to the aluminum plate

- (The ESC might later be bolted to the aluminum plate, TBD, but we’ll leave space for it)

- (We will also later cut some of the from and the back of the windsurf board, but not for now, so we install the mast 50 cm (a little far from the read of the board which is pretty narrow).

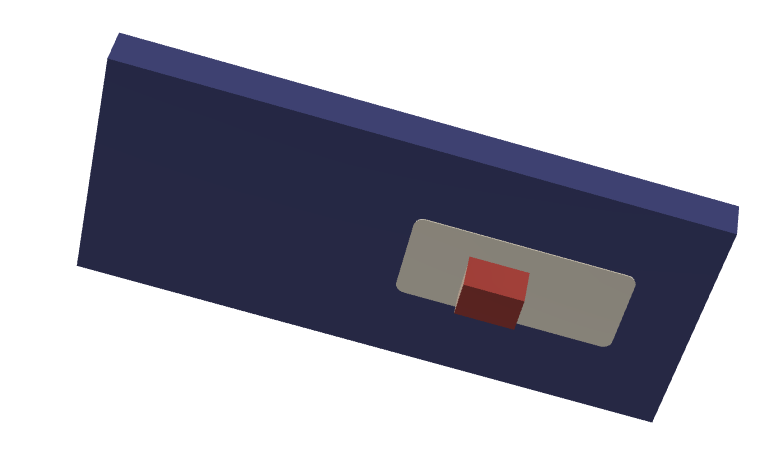

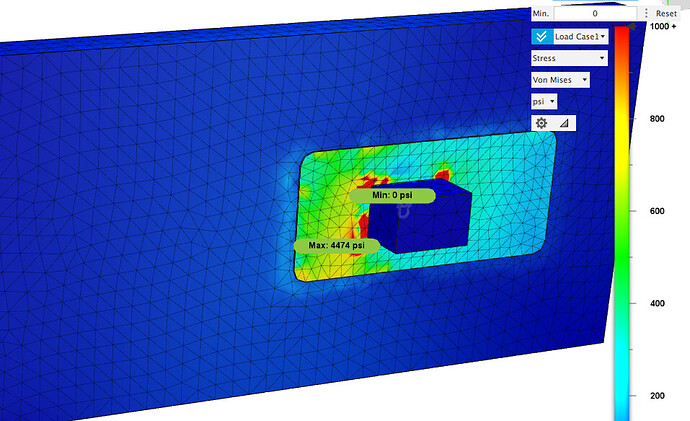

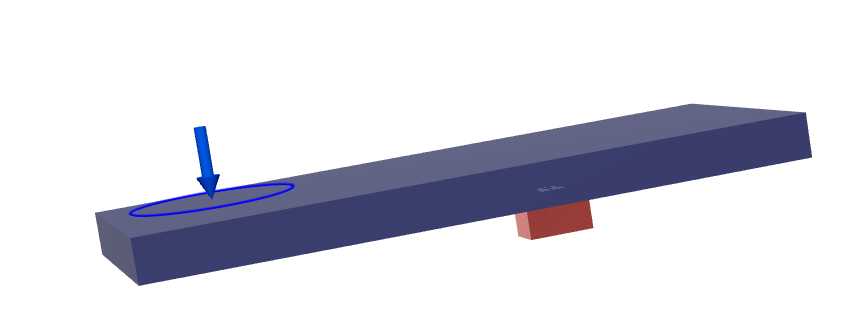

I used the simulation workspace of fusion 360 to determine the optimal shape of the aluminum plate (it’s a little bit of over-engineering, but it’s to show all the wonderful tools that are available to us today).

It was only a comparative study. Since I don’t know the strength of the board’s skin, I could only find the shape that was less likely to tear it off.

The simplified board and plate:

The simulation results look like this:

After simulating several shapes and sizes, the winning shape is as follows:

How did you define the loading? I think I’ll fix the mast and place myself on the board in a roughly estimated riding position. That should yield a pretty good study. Going through wing and stab loading might be difficult.

3rd_ave_lien I like the plate idea. I have bolted a foil mast for kite foiling to 3 windsurfers and 2 old super rockered kite boards and kite surfboards. It is very easy to through bolt them. I do it one of 2 ways. drill a 5/8" hole and epoxy a 1/2" brass or stainless tube all of the way through. Then put a bolt with a big washer or a small piece of marine Plywood to spread the load. if you are worried at all. I use bolts or threaded rod and barrel nuts for a smooth result on the top. Bolts are even fine for foot orientation.

The second way is to drill about 3/4" hole and fill it with epoxy and thickener, adhesive, or saw dust. Then drill through the hardened epoxy. 5/16" will fit 8mm bolts. Plywood on top, or top and bottom if you are worried.

Strap the battery on top to start and then when you have it all figured out make a recess and hatch using Michion’s seal method.

Thank you very much for your help, it is most needed and appreciated!

The idea is to, maybe, attach the ESC to the plate for cooling. Depending on how much heat we need to dissipate.

Today I am going to see how stable the board is on the water to try to estimate how much I will eventually cut in the front and on the back, and figure out where to mount the mast.

I also installed this mast plate over the weekend, here’s some pictures to give you some idea.

I think if I was you I would be tempted to put a layer or 2 of fibreglass on the bottom of your board for peace of mind to fully secure the mast plate in place.

Wardy, I like the mast mount plate. Were there any issues with the aluminum version? Corrosion or other problems next to the fiberglass? Did it work well as your heat sink for the vesc? I would expect that it did. Nice looking board!

Thanks @Kiteman54, to be honest I wouldn’t know if there was in issue with Aluminium and CF as it was all Laminated in the board with only the threaded inserts showing.

I never used it as a heat sink sorry, as my esc had its own box inside the hatch.

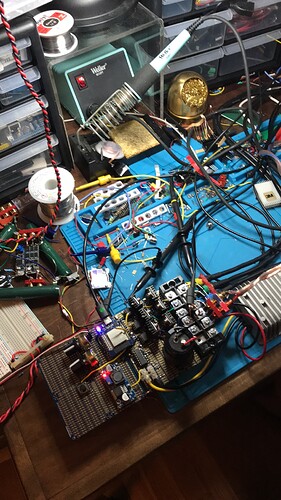

So, while my friend is modifying the board to accept the mast mount (more about that later), the work on the ESC is proceeding. After blowing many many parts, and finding out that 20A will cause the PC board traces to blow up also, my husband Charlie is building the real thing. Finally… As Rick says, if I wanted it next week, I would have ordered it next week!

Need to put this…

… into that!