thank you very much for your data. Sounds also good to me when it is working for you and I have around 15% less available current.

The following source I also found, where they did measurements regarding heating of the cell. They measured 21A for 5 min at ambient temp of 25°C as still fine (max cell temp <70°C). Our cells have in the pack maybe a bit warmer ambient temp, but sounds to me like still ok if it is pulling 15A per cell. I will watch the current and the temp and implement a measure based on that.

I have several of the 10S11P “robot” packs and am very pleased with them.

I think spec wise the Flipsky 75200 and 65161 motor is more “robust” than what you chose so be conservative with your VESC values as those cells will supply all and likely more than you require.

At 10S (lower V than you) the rig has all kinds of start power with the 65161 motor spinning a Flite prop.

I have had new riders on it that were over 100kg and no issue with lots of repetitive hard starts.

I have already worked on several things, but I was busy with some animal documentary. So was not able to provide updates. Now that is done, so I will start doing some updates here. (who is interested, here is also the animal documentary:)

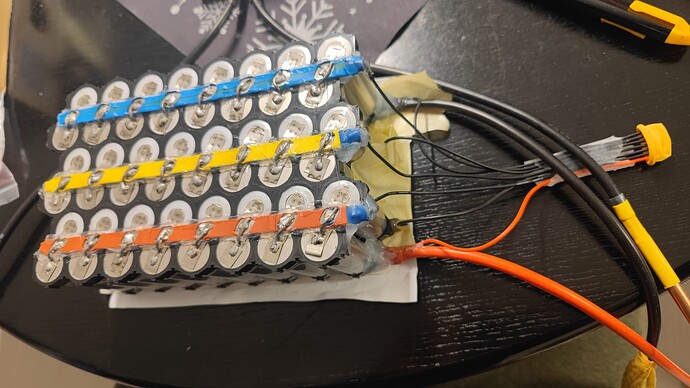

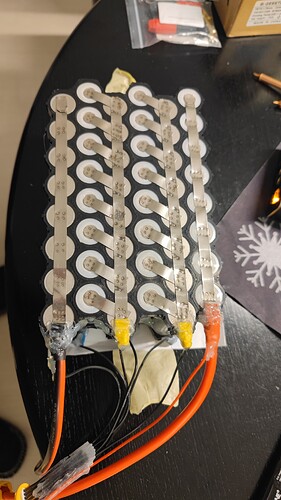

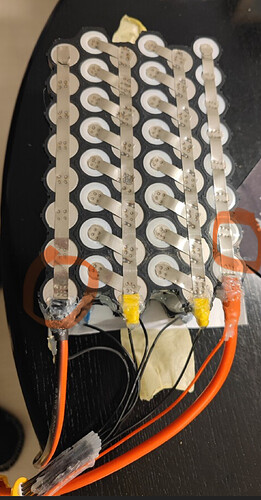

The Battery is done. I have 2 seperate 6s8p blocks created so that I can use a 6s balance charger which I already had. The blocks are coming without a BMS. All cells in parallel I have fused with cheap fusewire from alibaba. In series there is just 1 fuse behind both blocks to at least protect the battery in case I get a shortcut. After finalizing the blocks I added stripes of a sealing as shock protection before I wrapped it in pvc. The pictures are showing upper and lower side + the final blocks

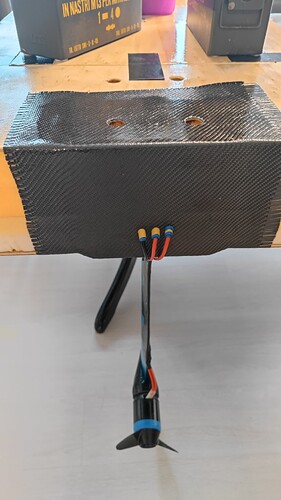

Here is now also the attachment of the motor to the foil. I had another good idea, so I changed my approach. I just printed a piece of plastic and put a clamp. First I just wanted to press hot clue in a pipe to model this peace of plastic to avoid setting up the printer, but then I anyhow installed creo and set the printer back to live. It is done out of PETG. It was not perfectly matching to the foil but with a heatgun I could fix that. Over the clamp I will stick a waterresistant tape to improve hydrodynamic.

To add, the cheap welder worked somehow. I also changed my strategy from 0,2 nickel plated steel to 0,15mm pure nickel. It was not the best e.g. welder battery got empty and I needed to do often breaks to reload. also the handheld cables got always to hot to hold. Spots were also sometimes not holding very good but with checking every welding point and doing a lot of them it was manageable. So who is tight on budget can go for it. I dont know why but somehow spots on the - side of the cells were very good and on the + sides pretty tricky.

I would suggest to increase your battery terminal thickness. At the marked spots you will gett the current of your 8P over the nickel strip, which will be too much.

You could extend the terminals and solder them to the nickel between the batteries, but it would have been better to solder before spotwelding, to avoid to heat up the cells.

See here, 1. battery soldered carefullly after welding, still OK after 4 Seasons.

2nd battery was soldered first and then spotwelded.

You are right I did not consider that. I think I will just double the terminal strip. That is I assume the best what I can do now.

ok, I put it into a calculation and 2 stripes are still by far to less. So I will put 3 layers of strips to get some heatsink between soldering and the batteries and then I will solder a wire on it. Thank you @sat_be, that could have ended bad.

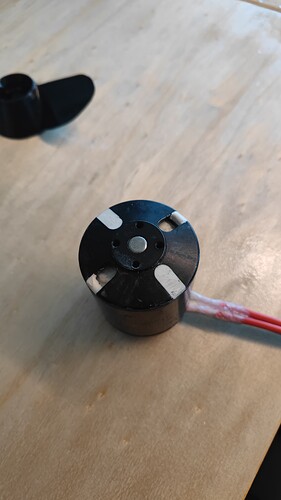

here is now also the motor. I filled it up with epoxy with 30-40% aluminium oxid (2-5 micron) to get the heat conduction improved. Also the magnets have a very thin cover. So there should not be any corrosion anymore. The shaft I cut of.

I have a kilo of it (so much more than I needed. So if someone also needs something for his motor, I can sent a bit for getting the shipping costs.

You could also solder short strips with the spacing of the batteries to a wire or copper terminal, spotweld that on top and fold over. If you can temive the existing terminal leads, even better, the you could do as I did (link above).

I did your last proposal now and had today my first test drive today. Worked well. Thanks

I also filled up the outer rotor magnets and reduced the holes at the top, to have less rotational drag:

Prop I 3D printed one out of the forum and attached a layer of epoxy (Volkers prop)

The board is also done. xps with a top and bottom sheet of thin wood to get forces not pressing into the xps. At the mast I doubled the wood and placed floor pvc parts, because that was for free at the store as an example and it is water resistant. I ued the additonal layer pvc because Iwas feared that the mast and screws on the other side are pressing in the wood and then the sealent epoxy layer at the top gets broken and water comes into the wood. One layer of carbon I placed from the mast side to the top side to eliminate that the different layers get separated by forces from the mast. More strengthening I dont think is needed, due to the thickness of the xps, the board is stiff. the wood I sealed with a layer of epoxy.

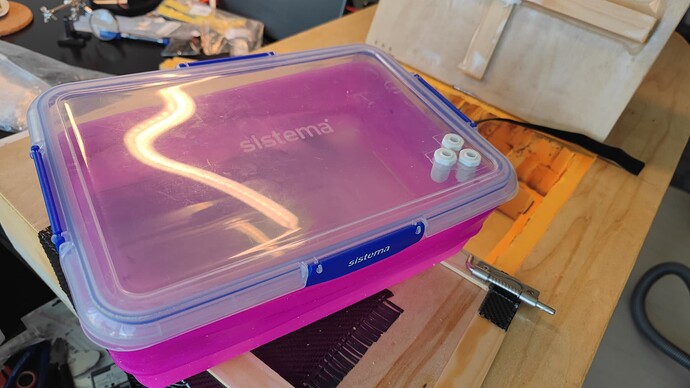

The electronics inside is in a normal kitchen box, which I wrapped around such a cheap china silikon ball to make it super tight. The box I am holding down in the board with a frame which I can snap in ontop of the box. Wiring just attached with adhesive stripes. adhesives stripes also used to smoothen the surface of the motormount.

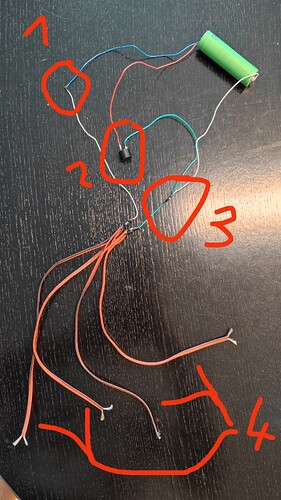

I also buildt a quick and dirty water detector.

I just opened an old damaged electronical scale and soldered the needed parts out. You cant see those small smd parts, but they are there ![]()

1: 10kOhm resistor

2. buzzer

3. npn transistor

4. sensor cables attached to the basis of the transistor.

As soon as one of the cables are in water, current can float into the basis and the buzzer gets activated. It works fine. But I havent built in the board yet.

Coming to the first test run.

The board overall worked fine.

A bit of rework is needed, because the controll unit gets quite hot. I hope I can do something in the settings to reduce it.

Those 3 wire inlets into the box are not perfekt waterproof. small drops came inside.

Does anybody has a better Idea how to make the inlets waterproof, but still easy to disassemble.

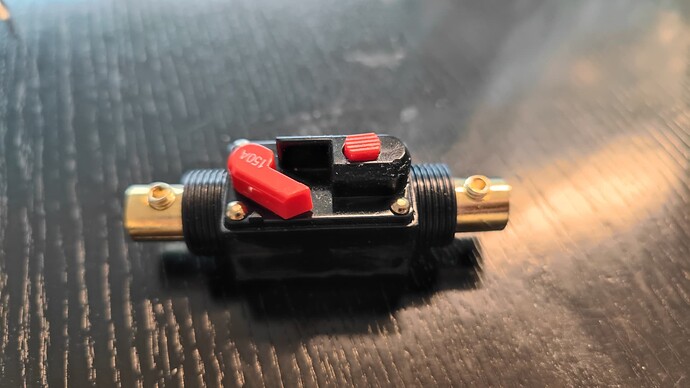

The last thing is that the cheap china fuse can by far not withstand what is written on it (150A). Something in the inside melted and now it is not possible to trigger or close the fuse anymore. Is that issue know or did I just could have a faulty part? Anybody also using that part or another better one?

Who wants to see what such a cheap efoil can do, see below.

I will improove the issues and then making a calculation, what it was overall. I assume it was more like 700€ but the battery is quite big.

People used those in the early days 2019/20 but most cheap ones could not withstand more than 60A, no matter what they were rated.

Better use an antispark connector like xt90s or QS8S. If you want a fuse, midiOtto 150 - 200A is rated for 58V and is quite compact. Works well in my 2 boards.

Here an update. I opened the fuse and the metal pins which are making the conection inside are held by cheap plastic which melted down. I excluded the fuse and did a second testrun:

(proper foiling skills ;))

Unfortunately the the ESC got to hot and is shutting down. I got a hint that maybe my prop does not have good efficiency. It is the prooven Volkers prop, but I printed with a bad printer and I deformed the prop maybe also a bit due to heat (I wanted to eliminate burrs at the edges and flamed it. The prop got very soft while that) and I also fixed an edge with UV-epoxy (I crashed the prop inside my door :D).

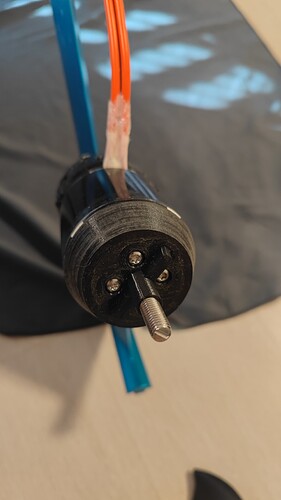

So I have bought a plastic flite prop and a 38€ flipsky aluminium folding prop (https://a.aliexpress.com/_ExFvH3u) and printed mounts for it:

I also bought a cheap china wifi amp/power meter and built it in the board to compare the new props (conection to smartphone works fine): https://a.aliexpress.com/_EzZ7fiA

The fuse I exchanged to 175A also from Ali: https://a.aliexpress.com/_EIVDPfu

So on the weekend I will test at least the flite prop. So let us see how it is going out.

Nice build. Can you please share the 3d printfiles you used to mount the props to the 6384 and what type of bold head is that? looks familiar.