New Update

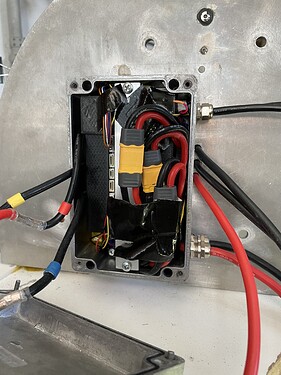

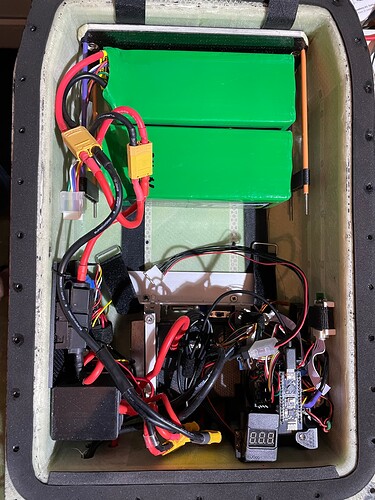

After water ingress (again) in the ESC box, I changed the concept and moved the VESC inside the dry battery box. As I don’t like water inside my box, the VESC is passively cooled through a heat sink laminated into the box. It is a tight fit with the additional VESC inside but it works quite well.

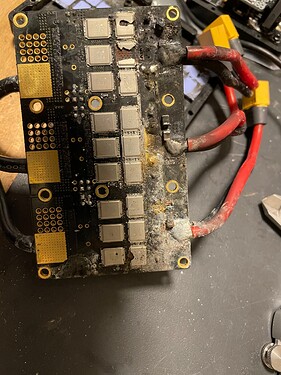

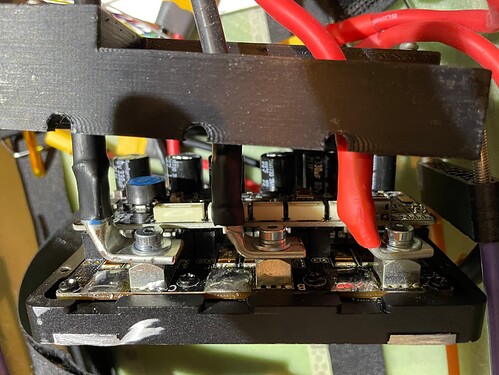

VESC 75200 after it got some drops of salt water

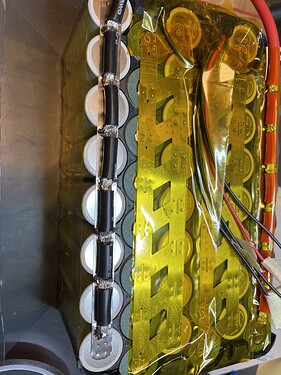

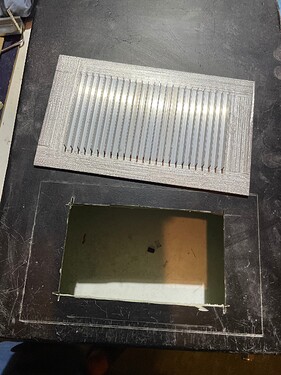

Cut the box with a dremel and fit a modified heat sink into the sandwich core. Made some 2mm holes for better bonding.

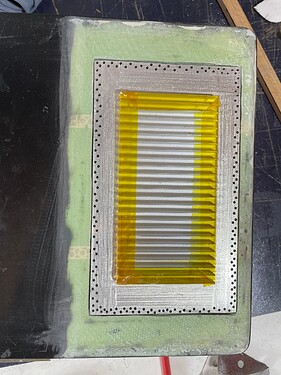

Laminated it in with 2 layers of carbon and one layer of glass and put it in a vacuum bag. Then coated with pigmented 2k polyurethane. For a good bond, the aluminum should be sanded just before laminating (<10min) as the oxide builds up fast.

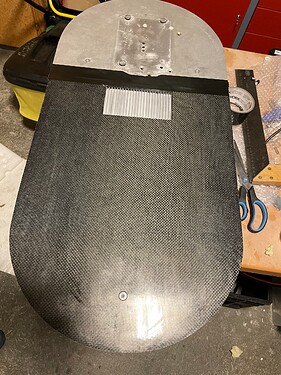

Had to cut out the bottom plate, the ribs are flush with the surface.

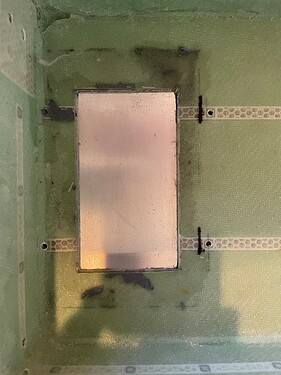

Inside the box

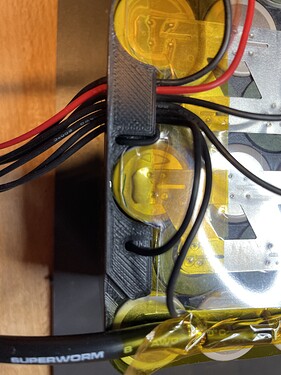

Added Würth screw terminals to the pcb

Clamped the 75200 VESC to the heat sink with a 0.5mm thermal pad in between

It’s easier to put it together, without the spacers in the back installed, the inflatable can be pulled over the box with the bottom plate installed. Once the inflatable is in place, the mast can be installed (including the spacers in the back), cables connected, then inflated.

Passive cooling seems to work, did a couple of sessions, no issue. The heat pad is important, as thin as possible, 0.5mm 12-14 W/mk. I had a 6W/mk 1mm pad first, difference is about 10° in VESC temp.