Thanks for your response. Setting tog_block_time to 0 means the steering without throttle is always active, setting tog_block_time to 1 does the expected action, it cuts off the steering without throttle as soon as the throttle is released, but only if steering isn’t engaged. If throttle and steering is engaged and I let go of the throttle, the steering is still engaged until I let it go. This much more child friendly ![]()

I set steer_influence to 0, and as expected the differential steering was non-existent, will report back later when I’ve found a good value for this.

I have the same issue here.

I have two RX boards. One is working perfectly. The second one has the issue above. Always had an antenna attached.

I checked the pins but could not solve it. Went over each pin with a soldering iron, etc.

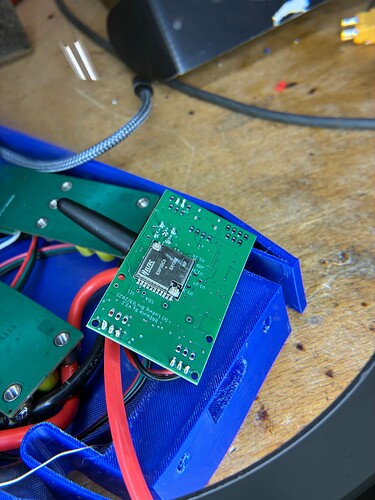

Here are some pics:

Any other idea?

Thank you Ludwig!!!

Did it ever work? Or broken out of the box?

If you have 2 boards, compare resistance measurements from each processor pin to gnd.

If you can’t solve it, you can always contact Jasmin for replacement

Hi Ludwig,

Is there a way to calculate the PWM0_Min/Max & PWM1_Min/Max for a dual-motor steering setup with vesc (75200 pro v2)? (or an acceptable range)

Thank you!

Pat

With VESC, use 1500 and 2000 as the PWM values and do the calibration in VESC input wizard.

Hi Everybody,

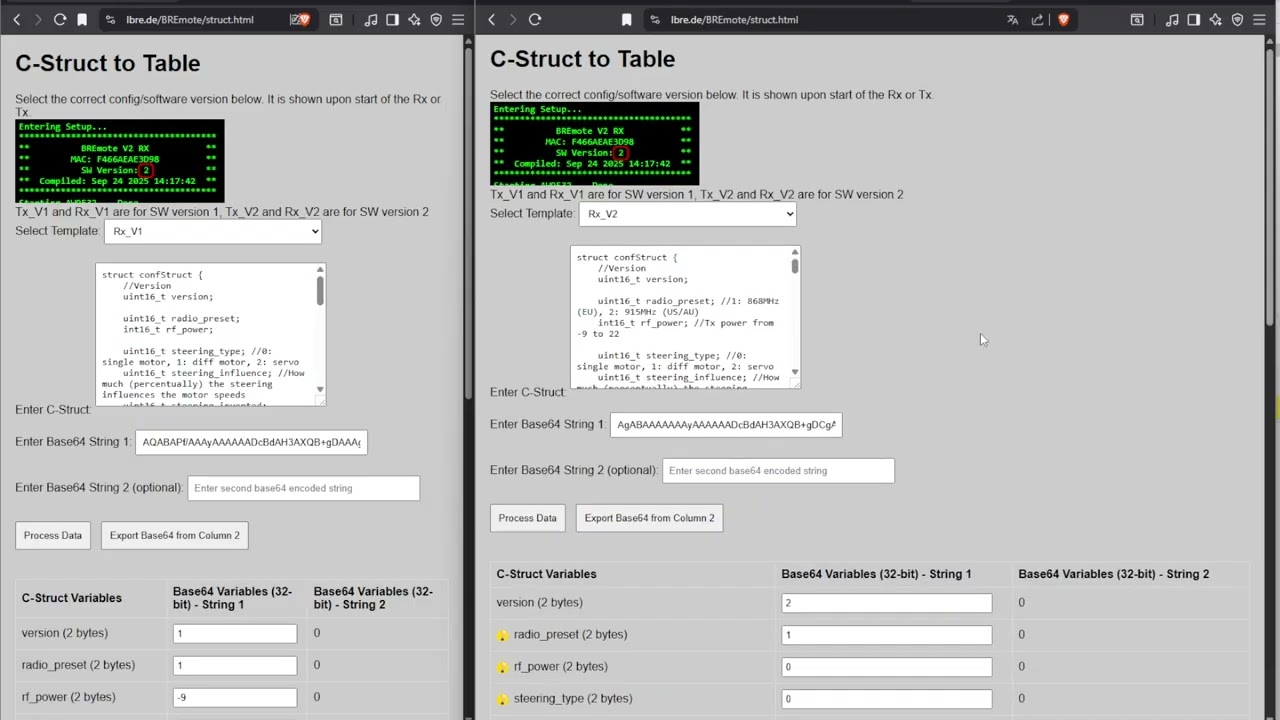

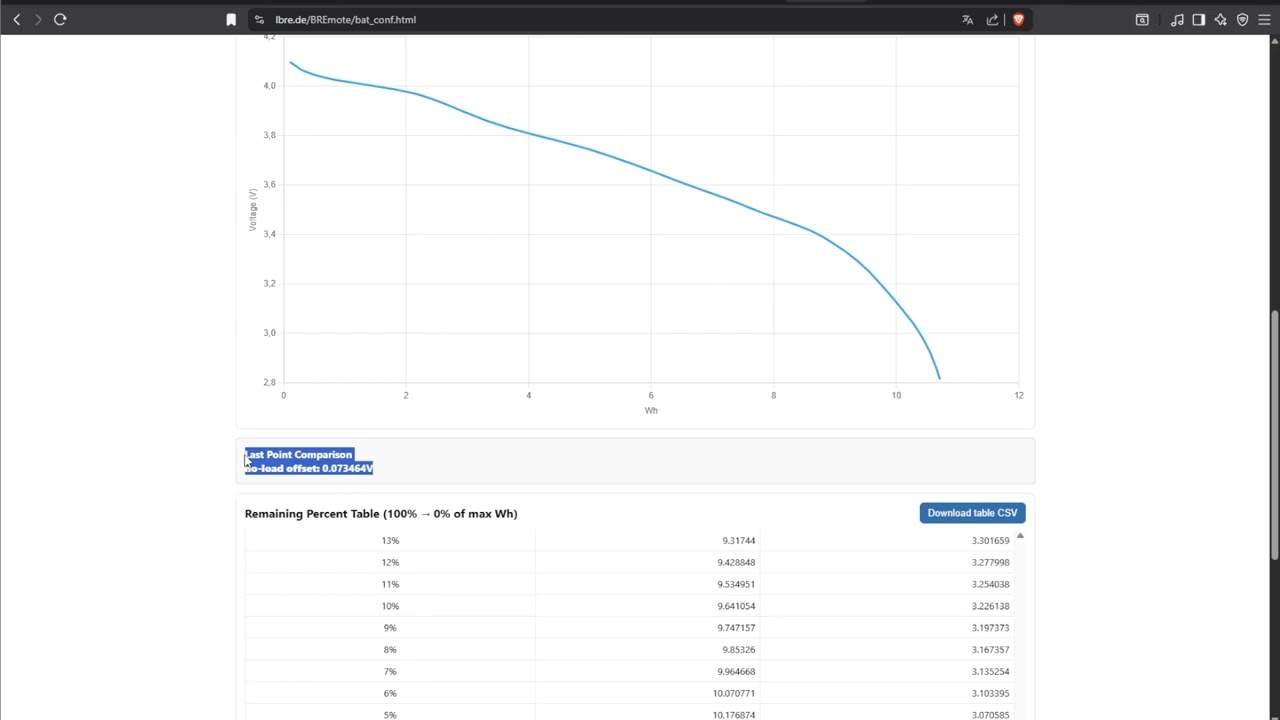

I recently uploaded a new software version to GitHub: V2.2.1

This includes provisions for followme-mode as well as a better way to estimate SOC

I have made 2 videos to explain the update process as well as the new battery measurement in detail. The lookup-tables I promised in that 2nd video are here: LUT

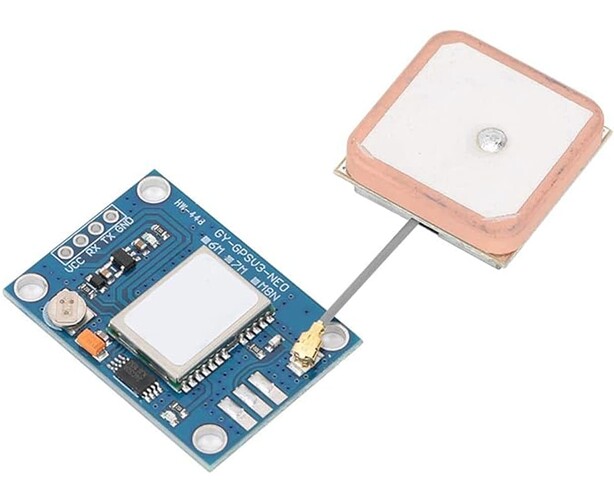

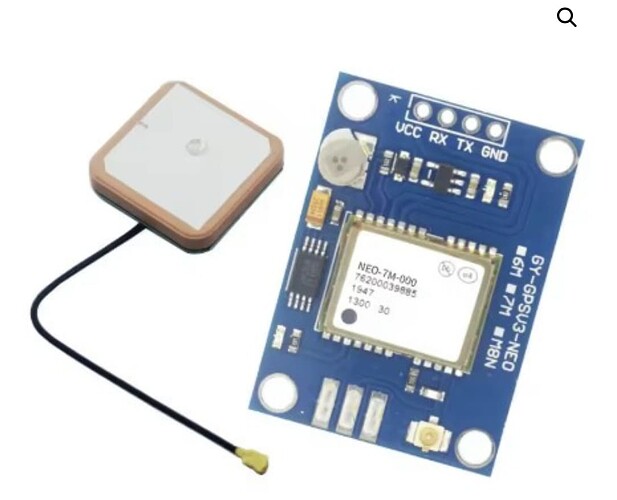

I didnt order with the GPS module but want to use one in the future (follow me) do I just order one with the same model name and board that looks the same as the one from the picture on openfoil?

For follow me you probably will need 2x BN-220 module, at least that’s the modules we are currently testing

Thanks for all your effort on these updates

For the battery calculator you used 1.2 Kw for your calculations.

Is this something you determined by reviewing log data of your rides? Or was this simply an estimate base on other factors?

The 1.2kW was mostly an example. Depending on the speed I foil between 900W and 1.5kW. And yes, a logger is really helpful for determining that

As im building the v2 right now (haven’t foamed it yet) can I get a BN-220, print the new hatch/lid thing and wire it in preparation?

Do you think follow me could work with a rudder over a dual motor boogie?

Yes, you can, but no guarantees it will stay that module or that the potting compound will flow around the GPS and cover it properly, this all still has to be tested. But I would be happy if you join that testing! ![]()

I have made a short video how to attach GPS:

I can also send you a bit of code to check functionality of GPS before and after filling, just write me a PM if you want to do that

Hi Ludwig

I’m so happy My prebuilt remote with all gps modules have arrived and it’s fantastic. Strongly built. You’ve outdone yourself and the service has been great.

The screen comes on and it goes into pair mode.

My question is where do I start with it to get gps working do I connect and program it or is it ready to connect to receiver? I still need to solder dual esc to receiver and gps module must get soldered to rx.

I just want to correct order for everything before I start soldering. I’m not the best when it comes to programming so any help will be much appreciated.

Happy to hear you enjoy so far ![]()

-

Connect everything according to the GitHub Connection Diagrams. If you can’t find your exact setup you can always ask the specific questions.

-

Configure to your liking. A video that helps with that can be found HERE

Thanks mate once again much appreciated and thanks for designing and sharing a amazing product

So again, remote still working great.

But I was having problems connecting it via USB or even charging. Took the handle off and there is far more corrosion, than should reasonably be, considering I rinse it in freshwater every use.

Trying to figure out what the problem is, my current theory is there is seawater trapped between the inner and the outer handle. Depending on how I store the remote, that seawater will slowly seep out, constantly covering the contacts with fresh seawater.

So if you use it in seawater, I would consider completely submerging it in fresh water for a while after use, instead of just rinsing.

Thanks for the information! Mind sharing a image?

Any chance the water between handle and remote dropped down while a charger was connected? Otherwise even with saltwater there should not be corrosion, only if/when electricity is added

I can take a picture once I disassemble it the next time, but it’s nothing special. Just the two outer contacts we’re not shiny gold anymore, but completely covered by that typical bluegreenish residue. It’s not a problem at this point, but far more than you would expect after just a week of use.

For sure, that is how I came to the conclusion, as the charger had saltwater on it after taking it out, even though I rinsed the remote and dried it for a half a day before connecting.

Is there a way to add an auto-off feature or is the on-switch some physical switch?

Wanted to take the tow out and found the battery completely down, either forgot to switch off or the switch got moved in the bag.

The switch is physical so no possibility of auto-off