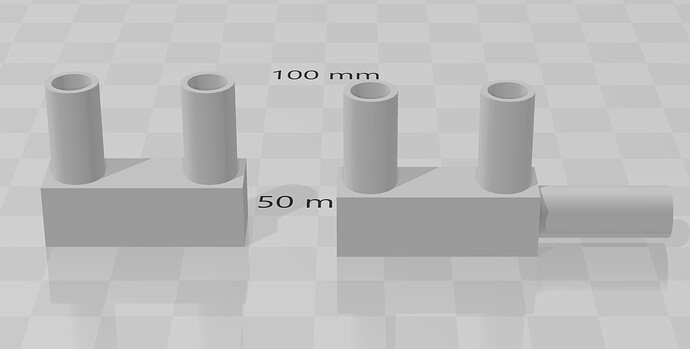

I am going to use these little adapters I made 3d printed.

@Larsb

Thanks for the feedback. I was quite disappointed on the quality of the included tubing. From what I’ve seen this is a comparatively expensive VESC to put such low quality tubing on - perhaps supply chain issues caused this. However easy fix to change that to something else.

@windego has a creative solution and OKPTOW seems to have replacement fittings and tube that look higher quality in this thread

Have you actually implemented one of these as I would like to have a better understanding of what flow rate is required to keep the temp at a good level?

Sure, but i don’t know the flow rates, just that it doesn’t heat up for me.

I use passive water cooling so the water is not pumped, it’s driven by the pressure created by the speed of the board. A small opening in the front of my clamp takes in water to the esc cooling.

I’m in sweden and water temperatures are always low so the ESC might get hotter if you’re in places like Thailand or the mediterranean (but from other users it seems to be no issue as well)

@Mantafoils would you remind us what your sea temperature is like in June July and August in UAE ? Do you still cool your ESC down with water on your 2023 range ?

@Larsb

I am on a large fresh water lake in Canada so water temp here isn’t very “tropical” either😀

Can you provide me with a approximation on how fast the board need to be moving before you get water flow through the VESC?

Of course mast height, tube diameter etc comes into play just asking for your best guess.

No idea, i need someone filming me to see that, outlet is on the bottom of the board. Might be a good idea to make it visible though, now that i think of it.

35 degree water in summer

The energy capacity of the water is so high that running it back thru should be juuuuust fine. And yes ram water pressure should work fine as well. The quality of the water tube shouldn’t matter a whole lot either - it’s very low pressure water

I don’t know the exact speed but I have passive water flow as my board starts to plane, this should be @ about 10 km/h (mast 75 cm, motor at about 10 cm, tube ID 8 mm)

@aemkei77

Thanks very helpful.

You mention your inlet tube is 8mm inside dimension. Do you use a reducer to change to a piece of tube that fits into the 75200 water inlet fitting?

I don’t have the original watercooling case but added a aluminum watercooler from ali to the 75200 alu case, thats why I use an ID8 tube.

With an ID6 tube you should get close to 60% of flow at the same speed

It matters since the pressure is so low. If you get a kink on the tube there is no flow at all.

The supplied tube kinks really easily and the spring doesn’t help. In the end i changed to a more flexible tube which works a lot better. I took that from an old brake bleeder kit so don’t ask what it was

I’m interested in understanding the 60% value

Not well versed in any of this so trying to learn as I go.

6 is 75% of 8 I think.

This has also got me considering using a larger diameter tube and then to a reducer before it goes into the 75200.

I’m wondering if a 10mm ID leading into the reducer would get water to the VESC at a slower initial speed?

volume flow depends on cross section (r2pi of ID6 is 56,25% of that of ID8 - 60 was a rough estimate) and speed

I am by no way an expert in physics, but I think that initial speed of water flow depends more on the height water has to rise than on diameter of the tube (when within reasonable parameters)

but with a bigger tube you get more water through your esc

Thanks for explaining the cross-sectional math - counts as todays learn something new every day goal.

As I have been asked by PM: I took this one in 40x120x12 and glued to the side of my vesc (its the one 75200 with aluminum case)

It is very effective: during one of my rides in croatia (easter holidays) the glueing broke and my vesc got into thermal protection. After cooling down I could ride for about 20 min again but stayed on low throttle, as I am not logging I don’t know exactly how much it takes to overheat.

After that I fixed the VESC to the cooler temporarely with a Ziptie , no more problems with overheating for 5 more rides

Happy to hear your zip tie fix is holding up. Sometimes simple is the best!

I thought I would update this for others to refer to during their design/build process.

I decided to implement water cooling by ram feed only (no pump)

I 3D printed a U shaped fitting that acts as a water return from one channel to other.

I used the original push in water fittings on the 75200 to connect the water tubes (quite a few sessions now and no leaks) so in my opinion no need to change those from original.

I used 8mm OD - 6mm ID (thick walled) plastic tubing to connect to the inlet and outlet channels of the vesc

I did a test today to determine board speed required to get flow. I added a short extension to the outlet side and aimed it vertically upwards to create a vertical lift of approximately 100mm from the intake to simulate anyone using a tall mast (normally my outlet tube is pointed down towards the water at the level of or below the outlet of the vesc to minimize the vertical lift of the water). At approx 5 km/h I started to get a trickle of water and as speed increased the flow gets stronger.

I don’t think it takes much water going through the vesc to keep it cool and my logs have never shown any increase in temp (within 1-2 deg C) and that is confirmed by touching the vesc at the end of a session where there has been substantial sustained current flow as I’m in the learning stage so have an above average number of starts in the session.