This is a local production

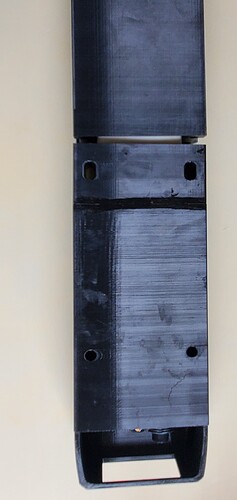

Comparison of new and old housing.

Please don’t judge me for this phase connector. This is not plagiarism, this is cosplay)

If it’s working for them, why reinvent the wheel.

Whats you housing made from? Looks like a single piece and not joined in that pic.

The body actually consists of three parts, two of which are glued together with two-component epoxy UHU, since the print area of my printer is only 250 mm. This is a banal Petg, but now I’m finishing printing the body from a mixture of ABS and polycarbonate.

Brave with a 3D printed case. I don’t quite have that much trust even at 100% infill. I feel I could potentially compress the 3D filament if I pumped a bit hard.

Didn’t work for me (goes to foil.zone)

but this one does 'Power plug EF8 for efoil battery

This connector looks like what Mantafoils is using for their TakeOff assist to connect their 96Wh battery modules to the center module.

I would also prefer die casting or aluminum, but I don’t have those options yet. Right now I am printing 8 walls and 60% infill. There is still glass-filled PET in stock, which can be further heat-treated, but it is very heavy.

An interesting connector, but the length of 121 mm is too long.

Good point!

20 characters

When you get to your final version do you think having a layer of bio-directional carbon over the top of the printed parts would be a viable option instead of using aluminium? Or using the 3D printed parts as the mould?

I’ve never owned a 3d printer and I was thinking for printing to use a combination of minimal infill and filling the void with chopped fibre and epoxy for the housing, then for something like the propellor to cover it in carbon fibre.

Also, what 3D printer do you have? As I am a few days away from purchasing as their is a sale on the 15th and 16th. I would really like to stop procrastinating and make the purchase of a 3D printer. If you purchased again would you still pick the same printer?

I have two printers from Bambu Lab -X1C and P1P. Now I would buy the X1C, the differences are small, but important for me. The bed temperature of X1C is 110 degrees, X1P is 100 degrees, and this causes deformation of the first layers when printing with plastic such as a mixture of ABS and polycarbonate. Overall, both printers are good for their price. As for carbon lamination, this is the last step I would like to take, as I strive for maximum simplicity.

Are there any ready-made passive antenna repeaters available for sale? If not, where can I read about DIY plans?

If you have your current antennae touching the case on the inside of your compartment and your compartment is a solid material, you can simply tape an antenna extension to the outside directly over where the internal one is. That is what I did for some time with my carbon prone board that had an internal compartment.

An alternative that works even better is the following:

Vecys 2PCS U.FL IPEX to SMA… https://www.amazon.co.uk/dp/B09PTGTSY3?ref=ppx_pop_mob_ap_share

Eightwood GSM 4G LTE Antenna 3dBi… https://www.amazon.co.uk/dp/B07ZYDZYYD?ref=ppx_pop_mob_ap_share

If you can, try to find a cable that is shorter. 3m is excessive and I will cut it down and connect another SMA fitting to it.

Hope that helps.

Try Taping outside of case with a 1/4 wavelength stripped casing of antenna cable, overlap of 27-31mm

Commercially foil drive sell one for a very high price. Not hard to make though.

Well, what I decided to try is a patch antenna from the quadcopter remote control + a flexible antenna from the radio station, which I will lay under the bottom and bring to the nose. Do you think this will work?

Everything works. Today, I started for the first time on my carbon board. Due to the fact that the antenna is quite short, the start was difficult. The antenna panel under the box is not secured in any way, it is simply pressed by the body itself, the clamping force is sufficient.

I ordered a cable with an RP-SMA connector, I will lay it under the bottom and bring the antenna to the bow…

That should do the trick.

The unit looks good. Do you notice any flex in the 3D printed housing?