Very interesting and thanks for this info. I’ve been struggling to get my foil assist efoiling even with 10s. It might be worth trying out the flycolor instead of the vesc and arc200…

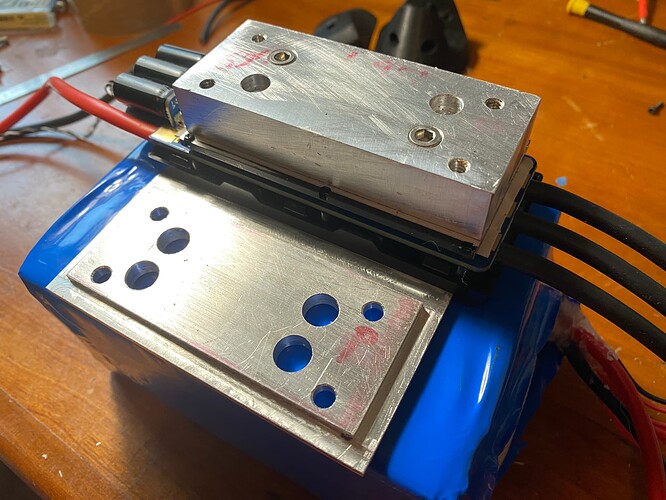

I just finished modifying a new Flycolor Flydragon 150a HV esc for ‘through the box’ cooling. I thought I’d relieve some trepidation if you’re nervous about what’s inside.

First disassembled the plastic case, which by some miracle they didn’t seal and fill with foam rubber like the 150a water cooled version.

Removed the 6 screws holding on the heat sink and machined off the fins.

Next made a block to add thermal mass and spacing and attached to thin plate with thermal paste and machine screws.

Then a second plate to glue to the box so I can later remove the ESC.

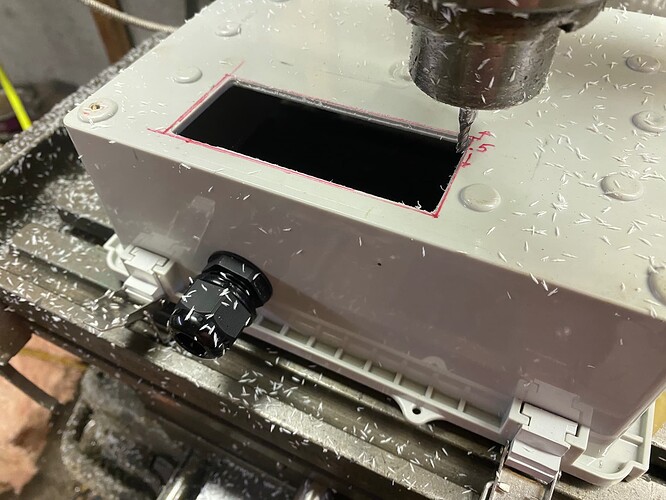

Window in box bottom…

And assembled.

Is this the 3-6s Flycolor 150a esc? If so, I tried this with my 6s battery and it worked great but 6s was not quite enough volts for me on my foil assist. It worked ok but I tried 8s and was much happier. The Flycolor esc for 8s was significantly bigger and I couldn’t get it to fit in my box.

It was the flycolor 150a 6-12s version. Aircraft version. It is 90usd on AliExpress.

I am not using an ultra small box , but perhaps the 150 a ESC might be too big. I did order an 80a version for 10s and it should be able to fit in my smaller box. I just haven’t tried it yet.

I should add, I just glued a 10mm x 60x 100 heat sink on outside then from inside I used double sided sticky thermal tape stuck the “as is” ESC onto it. It worked extremely well.

POD

I can appreciate how much work it took to make that heat block/ sink. Good job. Exposed to outside water/ air I bet the ESC doesn’t heat up one degree. Mine does heat up but just feels a little warm not the usual hot to touch

Jezza

I do not know everything but I do know that 10s battery ( providing they can put out 80 to 100 amps) should easily be able to get you up. I think the problem is that the prop is to big and ESC having trouble with too high torque.

Blockquote

I’m using a 24L board so it needs a bit more power to get on the plane and then foil. I’ve got a 6384 100kv so it will be interesting to see how it can perform on 10s compared to the maytech motor…

6s 8s 10s

My photos are of the 5-22s version, like Tosh.

But I only run 6S packs. When I didn’t have quite enough oomph, I switch motors from 120 kV to 170 kV. Problem solved.

But me xt, I’m going to modify a new 6S ESC by removing just the fins and using a tall enough block to just clear all the bumps (capacitors, etc). Then I can run my tiniest box 6S3P.

Everything inside the 6S version is filled with icky foam rubber so going through the top is the only way to get heat out of the package.

I would be very interested how the 80a Version works, because it is so much smaller than the 150a version. It would be great, if you could share your testing results!

back at it with a special carbon box holder that I can remove when I go surf foiling (without motors! )

I had a GO FOC SV6 laying a round, brand new. Just tried it… the FOC does not work (even detection) on 8S. BLDC fails most of the time. I’ve sent a note to Maker X to see what’s up

keep u posted!

I have been thinking about making a foil assist that allows you to swap ends to either efoil or foil assist. My son likes to efoil and I prefer the assist. I was tired of all the taping etc to swap back and forth. The axis mast is the perfect setup as it is hollow and also symmetrical allowing you to place either end in the baseplate.

I ended up notching out the trailing edge of the mast and bolting a backplate to the internals of the mast to mount the motor to. A clam shell style cover is added to each side to streamline the wiring.

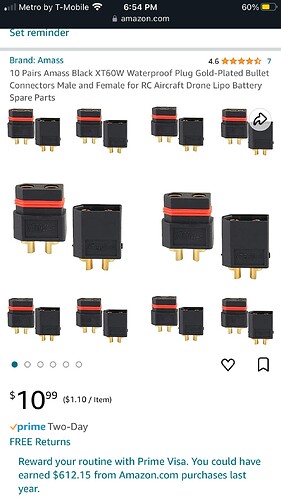

I am using a waterproof version of the xt60 connectors and potted the backside of the connectors in epoxy. The wiring runs internally and has the three phase wires routed to both ends of the mast. The end not in use is capped off and tucked inside.Uploading: IMG_4567.jpeg…

Processing: IMG_4595.jpeg…

Processing: IMG_4650.jpeg…

Processing: IMG_4740.jpeg…

Processing: IMG_4736.jpeg…

So far I have 10 hours on this setup (saltwater) without any problems and have been able to swap ends at the beach for my son and I to take turns.

That is a brilliant idea! Nice work. When you get a second, tell us what you have done to make the xt60 connection waterproof.

Thanks

Yes that is correct regarding the wiring. I used the connectors shown below. One has two wires, one connector with a single wire. I then potted the backside (where the wires are soldered) in epoxy. I use dielectric grease to help keep them water tight.

Might need to order some, thanks!

Have just tested the flycolor 80a v3. It is great. It could handle all the amps I needed.

I have it stuck on to an externalized cooling heat sink, and the esc only got warm after 20 minutes.

I am very happy with it.

I really think the 80a esc is all that I need and the 150a is unnecessary/too much.

Interesting, thanks for reporting back.

Is this the one you bought?

FLYCOLOR ESC FLYDRAGON-Pro-80A-HV3 Brushless outrunner Motor Speed Controller For RC Airplane - 80A Drone

https://a.aliexpress.com/_mtD8QfI

I only have experience with VESC so far. Do these Flycolor ESC allow to configure some settings like low voltage cutoff or max battery and motor current?

These measurements explain why the Maytech foil assist motor just can’t get running properly. The Maytech stator only measures in at 40mm.

I don’t know, 40/46 is 87% and i guess some of the cheaper 63xx motors were around that?

Could be lower grade magnets too i guess.