Yes, just the usual stainless bearings from aliexpress.

The motor being louder than it was in the beginning - it is because of the bearings? (I replaced with hybrid bearings)

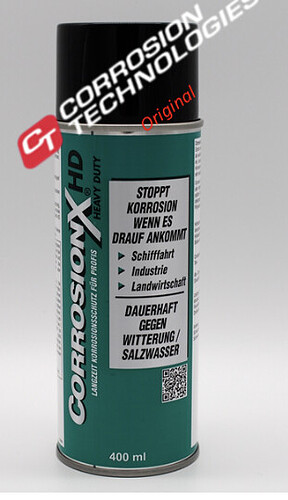

Did you buy corrosionX in spray with actual gas?

I have corrosionX in spray like bottle, but it doesn’t spray , rather drip like.

Yours also have very strong smell?

I personally found the ceramic bearings got louder after a few uses and I have never used hybrids. I don’t have the same issue with the stainless ones.

Yes, the corrosion x I have is in an aerosol can, but I have also used a regular non-aerosol also. I just spray/pour a little on and then rub it in with my hand, with a glove on and then you can just squirt it down in the bearings. Yes, corrosion x definitely has a smell, I have a truck so it’s not an issue.

The biggest thing I have found with the cheap out runners is if you just take 5-10 minutes when you get home to clean them up and lube them they are awesome. If you neglect them at all, especially in salt water, they deteriorate quickly.

What has happened to the motors which did not held up?

which one, the 6900 ?

I use the red one. I have never tried the hd, but have heard great things, but it is thick.

I have used both the regular and HD. I find the regular penetrates better and stays on just as long as the HD. The HD is very thick.

The oily CX (its green in colour)…is really good…ive got a spray bottle of it…lost forever…half the time i just soak the parts and pour it back into the bottle. Shouls.last ages.

K

Hey @Jesserosco Are you willing to share your STL files for this ESC mount? It looks great and I don’t see a reason to create one if this one is available?

I will 100% share it with you just DM me your email. I will say I do not use this setup anymore. I found it held in too much heat and I didn’t like it. I find that using thermal epoxy or glue directly on the heatsink works way better and is a lot less work to put together and comes apart easy if you need to change anything.

Many thanks, I’ll take your advice and stick it direct.

Hey @Jesserosco when you cover your blades in Epoxy, are you dipping or painting it on? Are you adding tiny bits of fiberglass to the epoxy mix for strength, or just straight resin? Maybe I’m overthinking this ?? ![]()

I don’t do anything anymore except sand them smooth. I haven’t had any issues without epoxy. But, when I did I used a brush to put it on, nothing additional added.

I’ve been running the mateksys pro BEC’s on my 3 tow boogies and they seem to perform a lot better. I haven’t had any weird anomalies like signal dropping for no reason, etc… I’ve also been leaving the RX board unplugged until after I plug the battery in.

Any issues without circlips on a non-folding prop?

I haven’t had any issues with the motors that I cut the shaft on, but I have had 2 rotors fall to the bottom of the sea on the motors I didn’t cut the shaft on. I keep the circlips on the motors I don’t cut the shafts on now.

Thanks. That’s a result I wasn’t expecting. I’ve cut my shafts, but left the circlip groove on, so will use circlips.

Ya it through me off when it happened. Again, I haven’t had any issues with the cut shaft motors not having a circlip. The non cut rotors slide on and off so much easier/smoother than the cut ones.

@Jesserosco finally getting there, setting up the Flycolors now, Just checking “Non Damped Mode = On”, and I assume for the other ESC the Motor direction is Reserved? Sorry for copying exactly but I just want to get this thing in the water for some testing and then I’ll do more research when I tweak it later ![]() Thanks.

Thanks.