Yes easily. I am 99kg currently and deep water start the Flipsky 6374 140kv.

With what kind of foil?

Look at his other posts linked here:

'Flipsky's new waterproof 6384 - #63 by lishine

(I just transferred the discussion to the relevant topic)

It is an extreme configuration of Veloce XL with 24L board while weighing 95kg

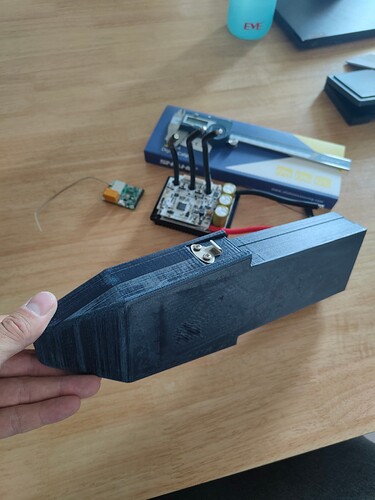

the print of the inner pod part finished OK, but with some underextrusion. Still feels adequately strong.

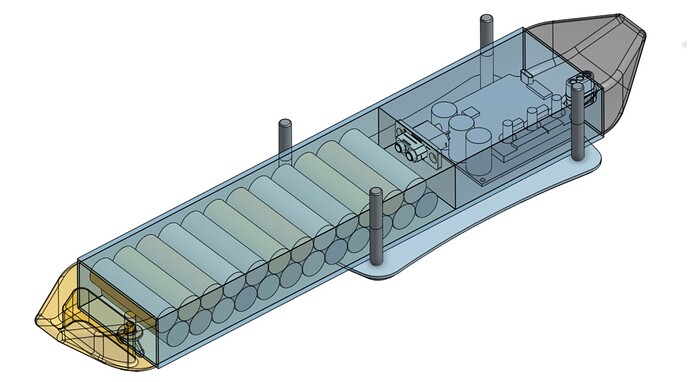

I have been thinking about a under foil setup a la foil drive V2, as my box placement on the takoon board was still a little probelematic.

Found some waterproof XT90 for that purpose, thinking about printed shell and fully epoxy casted controller and battery. That would split the cost of a failure between the pack and the controller, the 84100HP is only 80€. If I manage to get a good enough signal in BT, then I do not need a extra maytech receiver.

So the idea would be to have a cast shape with the 84100HP, XT90 in and MR60 out, ideally using the built in BT for remote.

The battery would have just a XT 90 and be potted, using some sort of balance board or BMS cast into the resin.

FYI I and a few others build flat box on top of the board .

1 - it will not add drag like fdgen2

2 - can be adjusted to be above the wing, above the center of lift

3 - still not modifying the board

Interesting. For me another important factor would be signal reliability. Moving my box from the back of the board to the front solved 99% of my issues in v1.

Having the receiver under the board, with a CF board, is probably a receipe for problems.

With the box under, you have a much cleaner Cable routing.

I will draw something to get a cleaner Idea of options.

I ordered a 1201 front wing should be a great addition to the 1300 for downwind and surf foil in small swell.

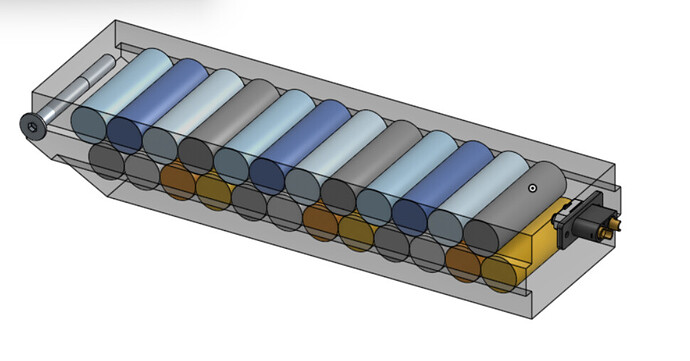

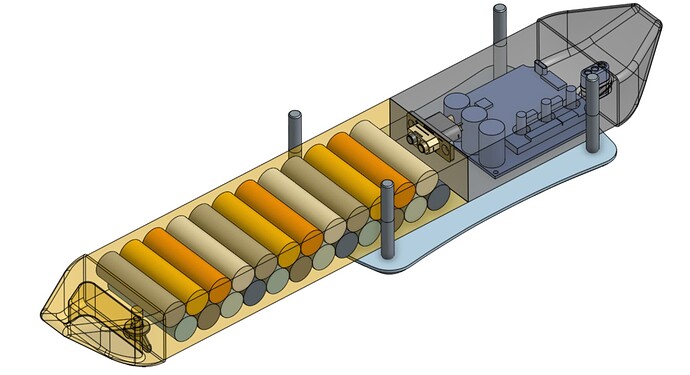

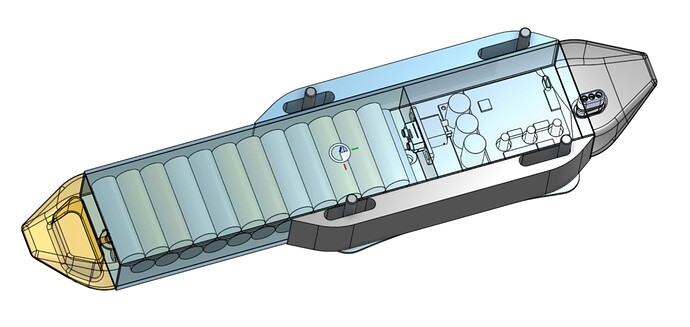

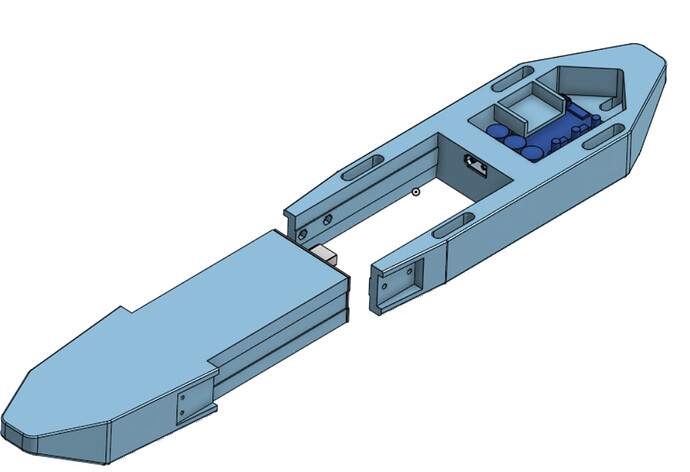

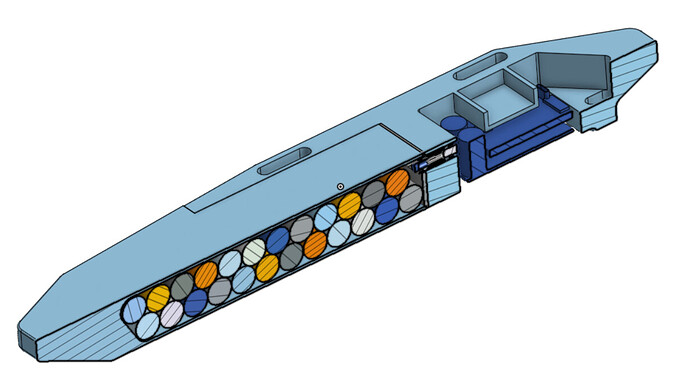

here is the idea, the bolt would secure the battery. 12S2P with P45B or P50B, waterproof XT90. MR60 for the phases.

I will think about ways to reduce the cast volume.

50mm thick by 500mm long, 120 wide.

Do you think 200 gram will affect riding in a way that you will feel? A sip of water before you go out (or the horror : changing into a wetsuit ![]() ) would be equal/more.

) would be equal/more.

OK, it’s three batteries but still?

Well, Saving kg starts with Saving 100’s of grams. I am undecided for now.

Getting ready for test for the New POD today, with the 1300 and the 4.2’

Also redesigned the 3 blade hub to have the correct angle for fully folded blades.

Nice, weight adds up but the maytech motor has been reported as being poor quality and too weak. Hope it works for you.

Today was a Real World test of dw with the assist. 30+kt winds against river current, nice short bumps 0.4-0.5 meters. Good feeling on the png1300.

Result, popped a mosfet on the already repaired 60100hp and finished the session by rock start DW ![]()

![]()

Box on deck

Pros:

You Can get signal underwater by having the remote in contact.

Signal IS very good overall

You get visual if any water Comes in

Cons:

Feet placement, I could barely pump the board

Can not paddle the board, box in the way.

Weight not centered (Can be fixed by having the box between both feets as suggested)

Power was barely enough to get started when not being carefull due to the very choppy water. With right timing with a bump, it was very easy.

The différence between the bare board and the assist equiped board was huuuge. Weight centering is probably a good chunk of that.

Second thing I re-learned is an assist could get you in a Bad situation if it fails far from shore, on a small board.

I had a life jacket just in case, but not being able to paddle is a Big risk.

Video :

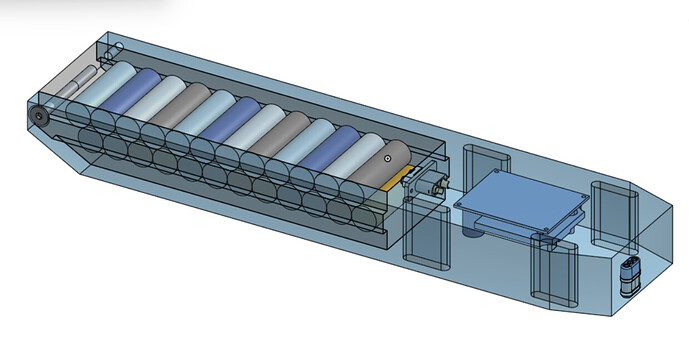

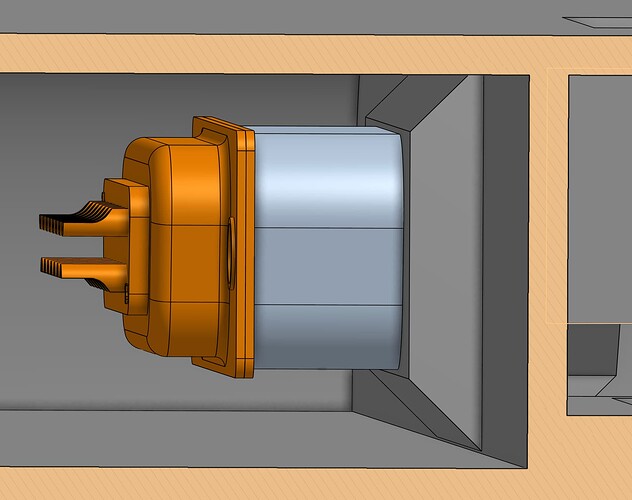

Making progress, with another concept, using a 80x40mm tube, and two cast parts that would slide in from each side. It only fits 12S2P 18650.

With this setup, the tube is only 2mm thick, so the cast part has to hold some constraints.

So maybe needs a extra part to hold the force, such as this that could be CNC or printed and glued to the tube :

Such a setup could really fulfill the “light” goal, for a assist only type of build, not really designed for efoil.

A few layers of carbon would do the trick, that’s what i would try first, minimal weight and a real simple lamination job.

getting somewhere I like with the design. maybe first prints this weekend

The 84100 has arrived, I will still use a maytech RX, as I fear BT only will be too weak, the RX will go on the little tray.

I received the waterproof XT90, and will use POGO magnetic connectors for balance with a custom connector (no internal BMS)

Ordered this for casting :

Amazon.fr

Lock I ordered and received those, they will go on the front to lock out the battery pack.

https://www.amazon.fr/-/en/dp/B0CJM71T1C?ref=ppx_yo2ov_dt_b_fed_asin_title

For cells, I have 30Q and P28 available, probably go with 30Q first as they are refurbish/salvage cells and not a big deal if they die from water or other cause ![]()

The back part is thicker to make sure the battery can slide in an out with the foil installed

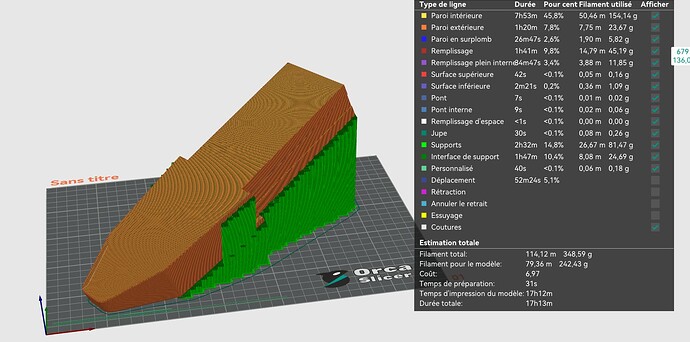

Glad to have a big printer

Great! I didn’t know, thought even to make one myself.

What is the advantage vs regular db connector?

btw found 20-pin magnetic

I have received these, they are small, feel good quality, have a spring and cheap.

Thanks.

Probably good stuff, other than thermal conductivity.

How do you cool the esc?

The locks seems very similar to the amazon ones, only cheaper as usual ![]()

The connector is nice!

Too bad I need 13 pins, but I will order some anyway, thanks for the share. I had 4 pins available and was about to use a few…

EDIT found 13 pins available, thanks for the heads up!

https://fr.aliexpress.com/item/1005007438592794.html?spm=a2g0o.cart.0.0.43fd378dq7QrUq&mp=1&gatewayAdapt=glo2fra

First print done, after a failed attempt last night (overhang too extreme)

PETG-CF

Second part is printing, testing again with PA6-CF (insipired by @hangloose )

If that fails it will also be PETG-CF.

The esc bottom is not cast, it is toutching the mast base plate. With a CF mast, it will not dissipate a lot. But my own and other people tests of the 84100 show that that should not be a problem, wether light efoil or assist.

So what you see as an advantage of this magnetic connector?

Do you print a cap with silicon to waterproof it?

In my over the top box battery design there is also a balance connector. I decided to use db connector . BTW are you aware of G20 connector ?

You can try ASA or ASA-CF (I didn’t yet). Advantage of ABS or ASA is 20% lower height.

I would not print anything with Nylon in water because it seems to me that it will absorb water. Also the creep of particular nylons is not good.

The G20 would be way to big I guess. The battery will be held on the fixed part where the controller is mounted, it give me a flat surface, I will make some kind of seal there, and apply grease on the contacts. The locks will keep the seal compressed and hopefully water out of the POGO.

Yes, for me as well the G20 was too big.

Me too compressing the connector cap against the esc wall. Just need some kind of cap for battery transport.

I will switch to pogo connector as it is slimmer and contacts are easily accessibe for cleanup.

You will use the one with ears or without?

Cap could be just the cut male part . It will be held with it’s magnets

Or the cap can be screwed to the battery case.

Where did you get Cad model? Can you share it? Thanks