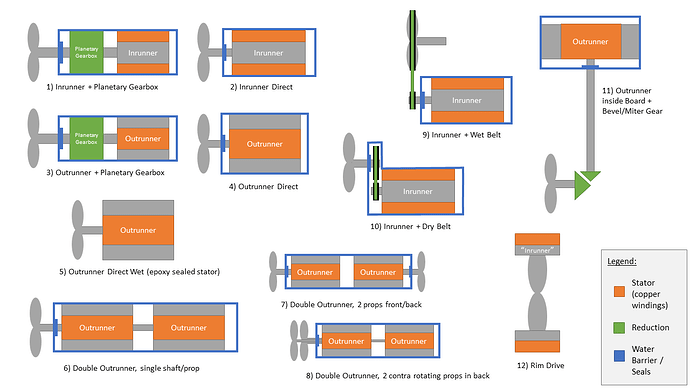

This is a WIKI post summarizing all the various drive systems that have been discussed here so far. I am sure I missed a few. Please feel free to update this post directly (I’ll make it a special Wiki post) and please feel free to add links to other posts and external references as you see them fit.

1) Inrunner with Planetary Gearbox

Pros

- High torque allows using large props (~120-150mm diameter)

- Good efficiency with larger props

- Manageable currents (between 15-50A) allows for cheaper ESC

- Inrunners around 500kv can be used

- Low drag with small(er) diameter inrunners

- Easy to cool

Cons

- Fragile planetary gearbox, not designed for fast constant input speeds

- Gearbox can be expensive and hard to find

- Additional weight, pod length and overall complexity

- High complexity (seals, couplers, bearings, gearbox)

- Gear noise

2) Inrunner Direct

Threads:

Pros

- Simple

- Quiet

- Smooth to ride

Cons

- High currents (can easily exceed 100A on start)

- Generally less torque with similar diameters

- Hard to make/find low kv inrunners motors with small diameters

- Reduced efficiency with smaller props or jet drives to manager higher rpm

3) Outrunner + Planetary Gearbox

Pros

- Planetary gear may last longer because of lower input speeds with low kv outrunners

- High torque allows using large props (~120-150mm diameter)

- Good efficiency with larger props

- Manageable currents (between 15-50A)

Cons

- Motor not easy to cool

- Bigger Outrunner diameter, more drag

- Planetary gearbox still a fragile component

- Planetary gearbox can be expensive and hard to find

- Additional weight, pod length and overall complexity

- Gear noise

4) Outrunner Direct

Threads:

Pros

- Availability of low kv Outrunners

- Lower motor cost

Cons

- Motor not easy to cool

- Bigger Outrunner diameter, more drag

- Generally higher currents, depending on prop size/pitch - requires better ESC, best with current limiting

- Efficiency loss with small props / jet drive

5) Outrunner Direct Wet (epoxy sealed stator)

Threads:

Pros

- Very simple

- Good cooling

- No shaft seals required

- Availability of low kv Outrunners

- Lower motor cost

Cons

- Challenging stator and magnet sealing procedure

- Motor bearing need to be replaced with ceramic or stainless steel ones

- Bigger Outrunner diameter starting from 63mm, more drag

- Generally higher currents, depending on prop size/pitch

- Efficiency loss with small props / jet drive

6) Double Outrunner, single prop

Pros

- Availability of low kv Outrunners

- More torque than a single motor allows for a bigger prop

Cons

- Cost – double motor, double ESC

- Pod length

- Cable/shaft routing may require special mast attachment design

7) Double Outrunner, 2 props front/back

Pros

- Availability of low kv Outrunners

- Twice the power ? Not sure

Cons

- Cost – double motor, double ESC

- Pod length

- Will require special mast attachment design with mast in center

8) Double Outrunner, 2 contra rotating props in back

Pros

- Availability of low kv Outrunners

- Torque on pod cancels out

- Supposable more efficient than normal props

Cons

- Complicated design

- Cost – double motor, double ESC

- Pod length

9) Inrunner + Wet Belt

Threads:

Pros

- High torque

- Possibly more robust than planetary gears?

- Cost

Cons

- Needs a robust pod/housing – might require CNC work

- Requires a belt system that works under water

- High belt speeds could be a challenge

- Additional drag from the offset pod

10) Inrunner + Dry Belt

Threads

Pros

- High torque

- Possibly more robust than planetary gears?

- Cost

Cons

- Additional drag from the offset pod and gear housing – likely more than with wet belt

- Needs a robust pod/housing – might require CNC work

- High belt speeds could be a challenge

11) Outrunner inside Board + Bevel/Miter Gear

Threads

Pros

- “Unlimited” torque by using large diameter pancake outrunners

Cons

- Motor noise and vibration

- Long drive shaft down the mast – engineering challenge

- Motor cooling

12) Rim Drive

Pros

- Minimal noise emissions

- Low space requirement - no shaft and no gearbox is needed

- Sealing of moving parts is not necessary, rotor and stator can be sealed hermetically.

- Since the blades are mounted to the rotor ring, there is no tip gap, reduces prominent source of noise

- Everything just sounds awesome in theory – can someone please build one?

Cons

- Reduced efficiency due to increased friction losses in the gap between rotor and stator

References

- Several posts in Propellers and Ducts - #17 by ELEVATE.rocks - Props & Ducts - FOIL.zone

- Rolls-Royce | Permanent Magnet Technology - https://www.youtube.com/watch?v=AZeWPlVoLko

– WIKI POST END –