Scroll up in the thread…

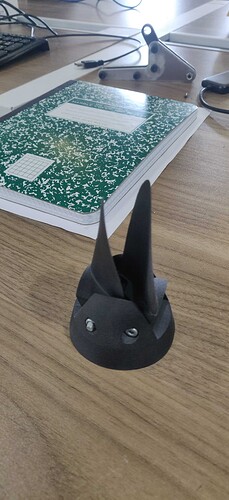

Orientation ist like this: Swabian Efoil build - #15 by Jatem

But no Support needed if you have a good blower from 2 sides on your printer head.

Thank you for the great prop design. I will print one in Fuse1 SLS Nylon for my build.

I find by google that page and love your design of the prop a lot. I was thinking about buying a Foildrive to add it to my Levitaz HA1600Pro foil and 100L Wingboard.

But the unhydrodynamic Prop is what keeps me off.

Does your Prop fit to foildrive?

I don´t want to build everything by by self and prefer to get it at least a bit plug and play.

Thank you, Armin

Hi Armin,

from my point of view it should mechanicaly fit. But i am not sure if the blades are big enough for the rpm. As i understood they use the same Motor but with a much lower Voltage. The Prop blade design is kind of the most important thing when it comes to efficiancy!

There is a thread where people try to build foildrives on theyr own: Foil Drive Assist, DIY - #330 by Pod

I think they should know if it really works…

Thank you.

Yes, the the blades design is super important!

Jeah, there would be so much nice solutions. But my main goal is to keep it as simple and reusable as possible. With my current setup i just need to exchange the Mast and have a full Kitefoil/Wakefoil/Surffoil equipment. I already have too much equipment and it tends to get more  .

.

Also, in a foildrive the pod is meant to be out of the water once it’s finished its job, so having an inneficient profile is not important as long as your power is enough to start flying…

Yes, but you can save a lot of more expensive Battery, Inverter, Heat, … if you have a more efficient prop which is more a question of clever design.

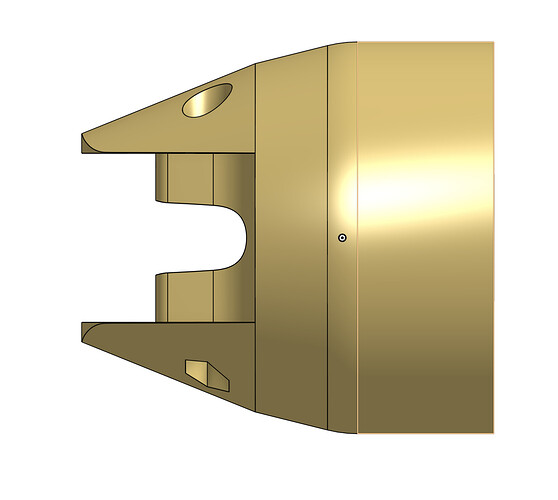

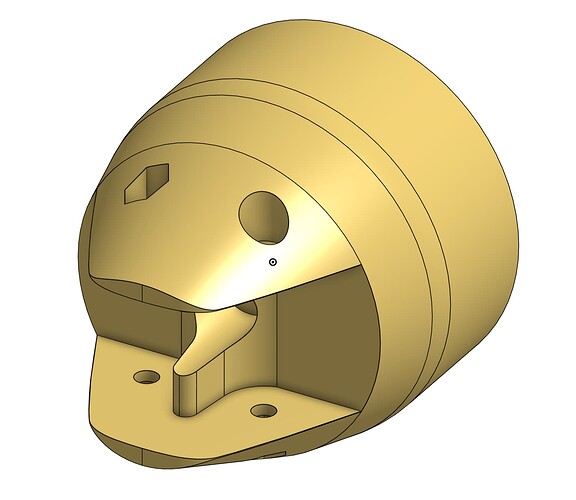

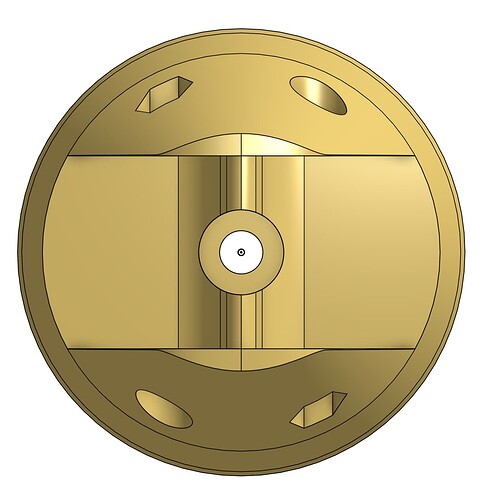

Hey Micheal, I would like to print your prop for my lift foil but I need to modify the file to fit the lift motor. Would you share the CAD files? I used the STL to copy the hub, but the blade is a STL and I can’t complete my assembly to check tolerances and fit. If not no worries but figured I would ask! Cheers, Theo

Hi Theo, what file format would you need?

I would not want to upload my Solidworks project data.

But if a STEP helps i could send you one.

by the way, can you set a delayed speedup in a lift efoil?

Because if you plan to print the Blades in PETG with epoxy layer.

You destroy them yery fast if you ramp up to fast.

best regards Michael

Yes STEP would be great, thank you!

You can’t set the speedup rate on the Lift but I’m planning to print PETG and laminate with carbon fiber. Hopefully it will survive, we will see!

Hey Armin, has this contra-rotating propeller prototype ever been tested ?

It is in use already: Candela C-8 first flight: Testing the most premium flying electric boat in the world | Electrek

Its good that they provide the efficiency numbers.

Lets compare it against values reported here for efoils:

Candela c8: 650 wh/km @1700 kg

Efoil : 50 wh/km @ 100 kg

So, per kg:

Candela: 0.38 wh/(kg.km)

Efoil: 0.5 wh/(kg.km)

I expected a larger difference. Especially since larger vessels should be more efficient

I wanted to now what it costs to print the two blades only with “Strength AND/OR impact resistant” properties on a professional site with high-end materials.

https://craftcloud3d.com/ which also offers a nice viewer btw.

PEEK is a lightweight, industrial-grade thermoplastic polymer with high-temperature and pressure resistance.

Carbon-reinforced PEEK is stronger and stiffer than normal PEEK.

PEEK and Carbon fibre PEEK are only available in ASIA (Mantafoil propeller secret material ?)

The interesting part when printing Aluminium, 316L Steel or 17-4 PH Stainless Steel:

- printing costs in Asia are 2 to 4 times cheaper than printing in Europe. what we could imagine. However…

- shipping costs Asia to Europe are twice as less than printing in Europe and delivering in Europe … just unbelievable !

Prices are in EU/USD. The total cost below is for two blades only, no hub. Ordering the hub in addition would be without extra shipping cost.

| 2 blades only | Print. cost | Shipping | Total cost | Ships from To EU |

|---|---|---|---|---|

| ABS | 6,59 | 8,33 | 14,92 | |

| HIPS | 6,97 | 11,9 | 18,87 | |

| ASA | 7,66 | 11,9 | 19,56 | |

| PETG | 7,66 | 11,9 | 19,56 | EU |

| polycarbonate | 12,69 | 8,33 | 21,02 | |

| Carbon fibre ABS | 12,82 | 8,33 | 21,15 | EU |

| Carbon fibre PETG | 12,82 | 8,33 | 21,15 | EU |

| FDM Polypropylene |

7,15 | 22,48 | 29,63 | |

| FDM Nylon | 7,56 | 22,48 | 30,04 | |

| Carbon Fiber FDM Nylon |

8,34 | 22,48 | 30,82 | |

| MJF Nylon PA12 |

13,3 | 24,48 | 37,78 | |

| Glass-Filled Nylon | 13,48 | 24,48 | 37,96 | |

| Markforged® Onyx | 19,67 | 41,65 | 61,32 | |

| Carbon Fiber Polycarbonate |

29,14 | 33,81 | 62,95 | ASIA |

| Aluminium | 44,36 | 24,48 | 68,84 | ASIA |

| 316L Steel | 73,04 | 24,48 | 97,52 | ASIA |

| 17-4 PH Stainless Steel |

111,88 | 24,48 | 136,36 | ASIA |

| Aluminium | 166,85 | 42,09 | 208,94 | EUR |

| 316L Steel | 220,77 | 42,09 | 262,86 | EUR |

| 17-4 PH Stainless Steel |

220,77 | 42,09 | 262,86 | EUR |

| PEEK | 68,39 | 24,48 | 92,87 | ASIA |

|---|---|---|---|---|

| Carbon Fiber PEEK | 68,39 | 24,48 | 92,87 | ASIA |

WIKI: PEEK can be processed by conventional methods such as injection molding, extrusion, compression molding etc. Thanks to these properties, PEEK and its composites are widely used in aerospace, automotive, structural, high temperature electrical and biomedical applications .

Last question: direct or via a hub ?

For a 316L print, direct via Sculpteo is -14%, in a EU to EU case.

The Asian manufacturing price remains unbeatable.

| 2 blades only | Print. cost | Shipping | Total cost | Ships from To EU |

Site |

|---|---|---|---|---|---|

| 316L Steel | 73,04 | 24,48 | 97,52 | ASIA | Craftcloud |

| 316L Steel | 220,77 | 42,09 | 262,86 | EUR | Craftcloud |

| 316L Steel | 213 | 11,66 | 226,99 | EUR | Sculpteo -14 % |

@leachim hi Michael, I really appreciate the time and effort you’ve put into your folding propeller. I am looking into the possibility of producing a community designed and built metal prop for less than 200€ and think your design would be a great candidate. Would you mind us casting and testing your design?

You can check out the link below.

Best mani