I built a tow boogie based on Valhalla’s board setup.

I wanted a battery with good durability (cycle life) for plenty of tow boogie sessions, so I used li-ion cells rather than lipos. The cells I’m using are Molicel P42A, bigger form factor 21700 cells, which are a high current cell with a long rated life of 500 cycles at 10A discharge to reach 80% capacity. I didn’t want to be throwing away a puffy lipo prematurely, and I’ve seen ratings for the Tattu lipos at around 150 cycles. The battery build is detailed here…

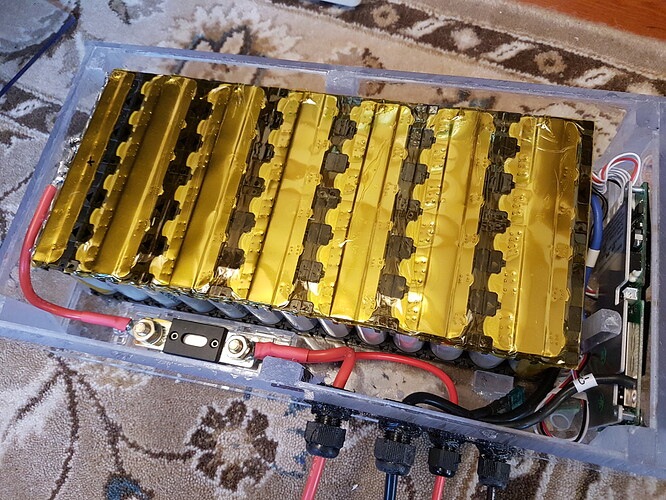

The battery pack is a 13s6p configuration, for 48V and about 25Ah (total capacity 1177 Wh). It is spot welded with a kweld at 30J, with 0.3mm pure nickel 30mm wide strip for ample current carrying capacity. The BMS is a JBD 30A from lithiumbatterypcb, wired for charging and balancing purposes. Discharge leads are 8 gauge silicone wire connected directly to the battery through a 200A fuse. BMS wiring is tidy, with no crossing wires. There are 2A pico fuses where the balance leads attach to the nickel strips.

I initially considered soldering to the cells, but the chance of overheating cells and potentially leaving a blob of stray solder that could short out the +ve end of the cell didn’t seem appealing, so I picked up a kweld spot welder.

Liion batteries must be treated with respect, and should only be built with ample care and research. I highly recommend tidy and parallel routing for balance wires, with nothing pressing/rubbing on them, because otherwise the balance wires could wear through and short out your cells, causing a fire. The same thing can happen if you use 6+ pin plugs with an RC balance charger, and they get some saltwater into the plug or if the pins short out. With the BMS wired for charge only, I use a separate xt60 plug for charging, and there’s no risk of shorting it out. There is also a 30A fuse between the xt60 charge plug and the BMS. I can use my phone via bluetooth to check that all the cells are balanced.

Battery is in a 4.5mm polycarbonate case, glued with proper acrylic type glue on bottom and sides, and the top is stuck on with bostik ISR 70-03 adhesive which can be removed if required.

The Maker-X Hi300 (75/300) vesc works flawlessly with the flipsky 65161 motor, perfect auto tune first time with large inrunner setting in the vesc tool. It’s running FOC mode. I didn’t put any corrosion x inside the vesc enclosure, because I’ve read that it can destroy heatsink silicone pads. The aluminium VESC enclosure is passively cooled, with an adhesive thermal pad on base of the VESC, and warms up about 30 deg C from ambient after an hour at cruise speed, 45 deg C above ambient if I’m pushing it. I was surprised how quiet and smooth the motor runs. The alu enclosure is a BUD Industries AN-1306-A from Amazon, which has a much better quality seal for IP68 rating than the aliexpress enclosure I initially purchased. I’m using a 1m aerial extension purchased with the Maytech remote, otherwise there is poor reception from the alu case. I glued the thin aerial wire inside a short section of 8awg wire casing with Bostik Simson ISR 70-03 (excellent black sealant+adhesive you can see on all the PG-9 glands), and that way the PG-9 on the top left could clamp down and seal on it.

The maytech receiver is on the top right of the pic, and you’ll see a small NRF51 bluetooth module I bought from Maker-X on the top left, which I’m currently using for bluetooth to connect the android VESC tool app (the NRF51 isn’t required, and actually takes away useful UART data that the maytech remote would otherwise show - it’s just for more detailed logging data). Make sure your TX pin on the receiver (or NRF51) is connected to the RX pin of the VESC, and RX to the TX pin, if you want UART to work. I’m using PPM mode (PWM). The maker-x vesc can be programmed via usb cable and the pc VESC application.

The speed restricted modes on the esk8 remote are very useful, I have it limited to 70% throttle.

It’s a 100kV motor, which has more than enough speed for a tow boogie. I half filled the motor with corrosion x, by taking off the cover on the shaft end, to reduce the likelihood of corrosion.

An XT90s is used on the discharge leads from the battery to the vesc, as this has an antispark resistor built in. XT150 connectors are used for the three phase wires, without using the xt150 plastic covers, and I filed down the widest part of the connectors so they can be slid in and out of the mini waterproof connectors for mounting inside the mast during assembly. I only needed one set of XT150 connectors between the VESC and the motor, because I can slide the connectors through the PG9 glands and the mini waterproof connectors if required.

It’s all stays dry inside the pelican 1450, with some grease on the enclosure and pelican seals. The battery and vesc enclosures are also tested as waterproof.

Maytech esk8 MTSKR20WF V2 remote, with corrosion x inside, and silicone conformal, and then I put it inside a piece of pu kite bladder (sealed the ends with a heat gun at 280 deg C). These remotes don’t like getting wet.

It’s an Axis 19mm aluminium mast. I cut a “450mm” mast in half, but they are actually 430mm so I’m using 215mm. The cut end was threaded with a m8 tap.

I designed a 3d printed mast plate which braces solidly against the plate on top, and also clamps onto the board with 2 small screws. I’m using ACM 4mm sheet (200*400mm) to support the mast onto the board, glued down with Bostik contact bond industrial strength adhesive (w toluene it actually sticks to the PE surface of the boogie board). ACM is a composite polypropylene sheet with very thin aluminium on each side.

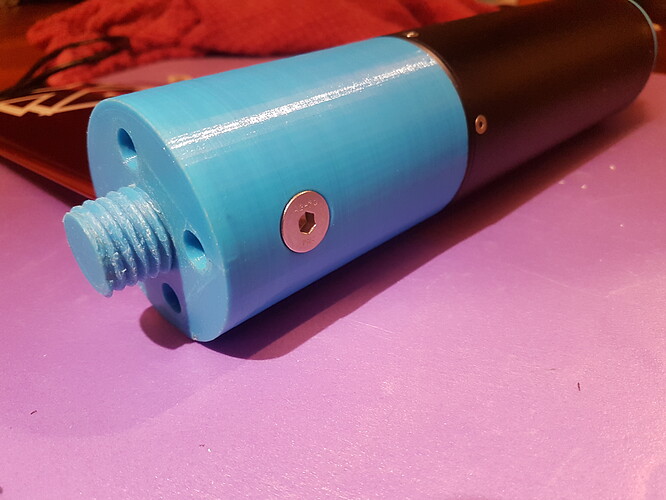

I designed a 3d printed motor mount which doesn’t required the 3d printed part to be under tension, and should hopefully be durable. An aluminium 2020 extrusion bracket holds the motor vertically to the mast, and then the 3d printed mount is controlling rotation downwards against the front mast bolt. It has a screw on nose-cone, which covers up the bolt holes for motor mounting, for smoother hydrodynamics.

The 10’ tow rope attaches to a 25mm alu square tube, providing a solid tow point attached directly to the top mast bolts, it’s very rigid.

I would recommend using a large adult (42-44") boogie board. This one is a youth size 39", and I added some closed cell foam to the front to help keep the nose up at speed (ala Naiad). I install a piece of acrylic (150mm x 150mm) for the trim tab, with an angle adjustable mount, so I can tune how much trim it needs to prevent torque twist on startup. When you’re up to speed, the high angle of your tow rope causes it to run very flat. A speed adjustable trim tab might be a good upgrade in the future.

I’m using axis 1010 foil which is an efficient wing and pumps great. The manta prop works well.

Run time is more than 1 hour of continuous foiling. I’m using 16-18A from the battery when I’m cruising at low speed.

Loving this thing. Way more sustainable than a power boat. Perfect for glassy flat days when I can’t kite foil. Whipping into unbroken swell is primo.