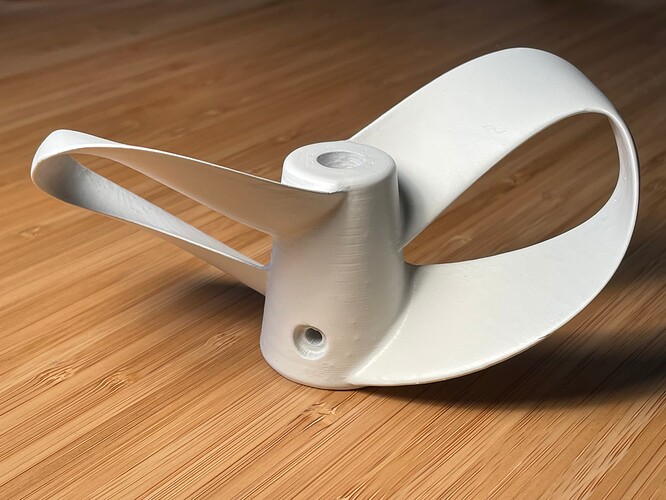

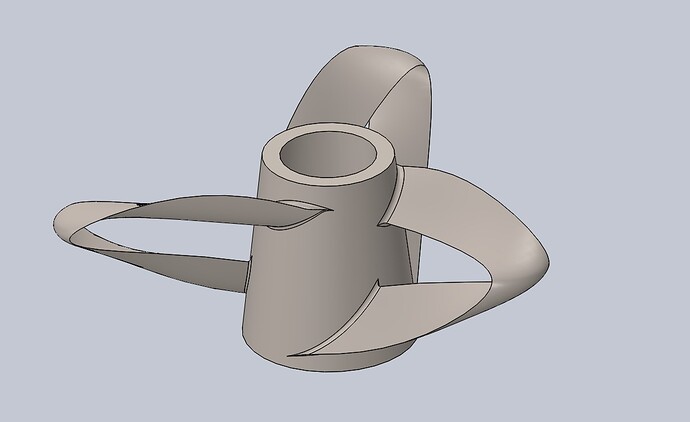

My third one out of PETG. Size is 130x0.8.

Much more easy to sand with that gap between the blades, still annoying.

Printing 0.2mm layer → sanding → filler → sanding → painting

Not perfectly smooth but should do the job.

That look like it could shovel the water from the sides to the middle. Looks very nice. Did you thought about my Idea turning the profiles on the sides that force goes into the middle. Maybe that could get an effect.

Wow, that looks really nice, can you judge the strength by squeezing gently

Hello Various design i love it! If you print with a layer at 0.16 you don’t need to sand it just varnish and i have better résults with pet but slow printing and 100 infill is for me the minimal set up for qualité print so 25 30 mm/s with my old ender3 if you have the file for fusion 360 for share i can modify the hole for test on my 8mm axes

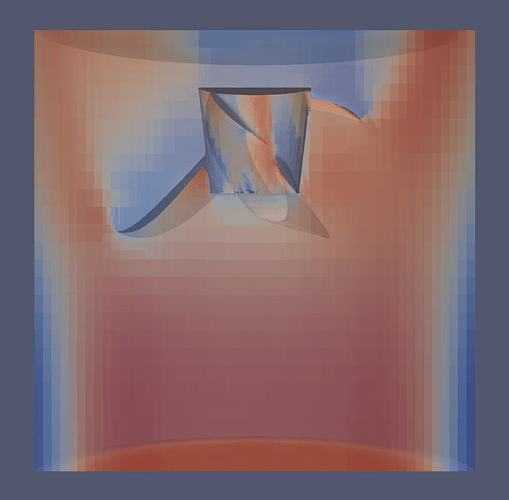

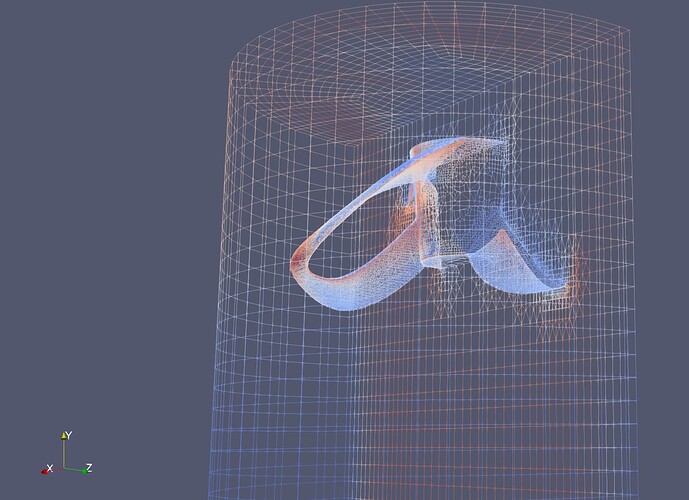

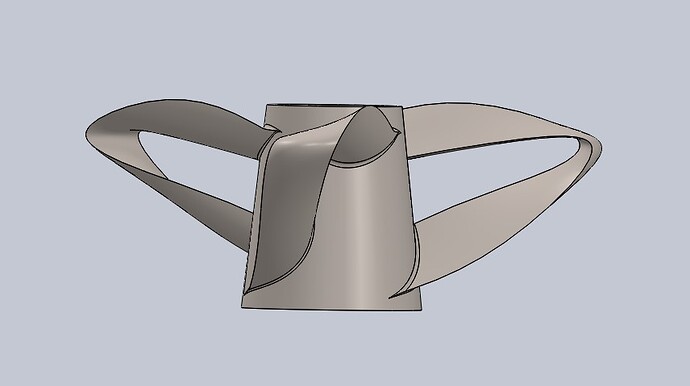

Well I’m not competent with simFlow or OpenFOAM at all yet, but I think I got a result that definitively shows that my first attempt will not work very well!

I have red as high Y velocity of the fluid, and blue is low. You can see that it’s far from uniform across the blade, with an interesting spike right at the tip.

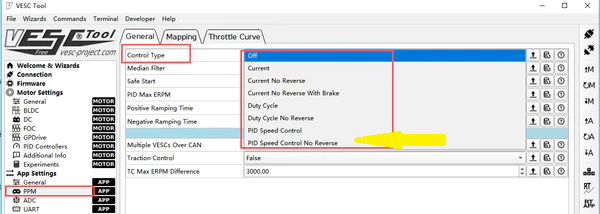

There’s a need for a measurement protocol. As ideas are blooming here and there, how could John in New-Zealand convince Sarah in the US that his new toroidal prop setting is the most efficient to date ? A result in Wh/km or miles won’t be enough. A cruise control with stepped rpm probably… is the “PID speed control no reverse” VESC feature appropriate ? While an arduino assembly could do this, I wonder what commercial remote would be capable of it ? There are great possibilities on the open source side where we could develop this function see @ludwig_bre project 'BREmote - DIY Remote

Just found the OpenFoam user Guide (from their twitter account)

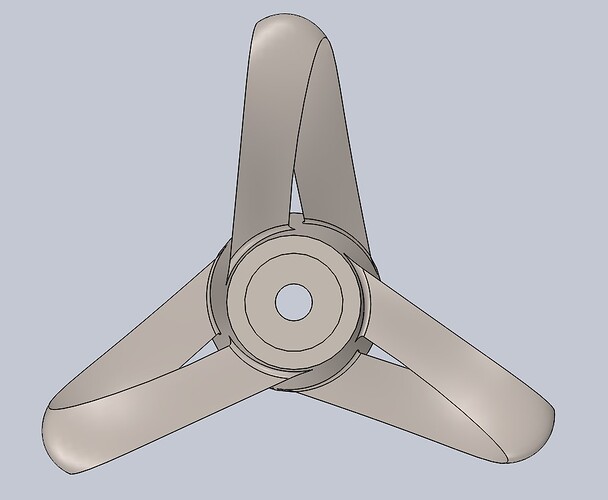

How difficult is this design to machine, how efficient is it and do you have test data?

Not easy to maschine, I think you need a 5-axis cnc. Better print it in plastic, test until an efficient design is found. In the end it might be cheaper to get it printed from aluminium, than machinig it.

Does anyone has been on the water for testing so far?

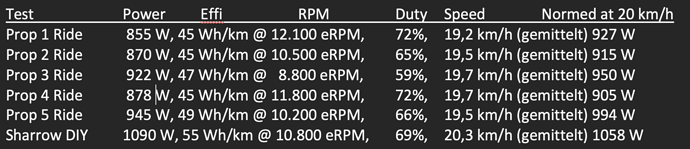

Good you ask, I’ve been testing today

The results are worse than my normal props. But not far off.

Tried to hold speed of 20 km/h for comparability. Last number is the normed speed at 20 by square law.

Did static thrust Test at 3 kW while prop was visible in the water and there was no bubbles like you have on other props. But I think I heared some cavitation noise. But did not see it.

Have all those tests been performed without duct ?

Underwater test (power, hasard) of 3 kind of props: traditionnal, toroidal and Sharrow:

Could you please post the different shapes of the props that have been tested, thank you.

Results are in!

The propeller adapted from the thingiverse model on post number 24.

It worked but pulled 1500w @ 20kmh, I normally pull around 1000w or less @ 20kmh on my cut down flipsky propeller.

It also made a strange whooshing noise like a washing machine

My lakes are frozen now, had to break about half an inch of ice to get to a small open water streak yesterday. I’ve changed board, wings and stab and i have some learning to do - no propeller testing for me for quite a while

In hibernation until spring

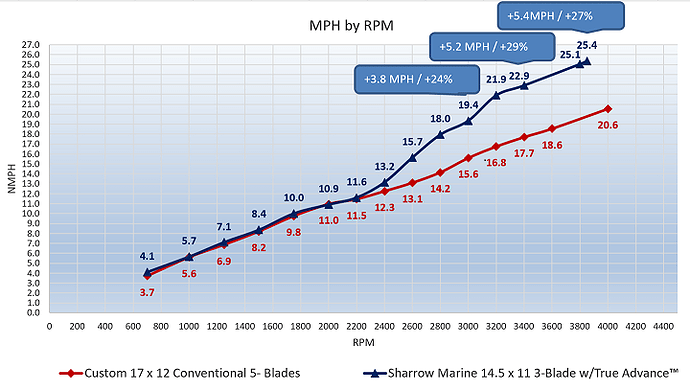

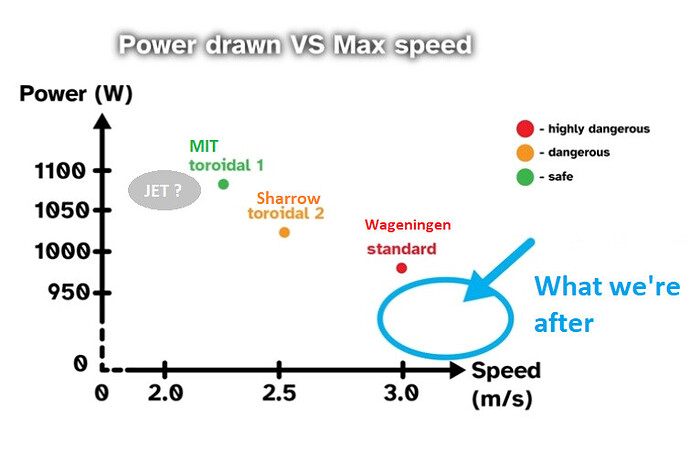

So now, we know what to expect and what to look for. It will be interesting to position the dedicated efoil results in a diagram like this one found in the above submarine video :

'https://youtu.be/w90gM7bGdvk?t=364

Another point is where to position the costly (*) jet option offered in 2023 by Fliteboard, Takuma, Foil, Manta (…) +Audi in the above diagram. If it is worse than today’s MIT prop (so left of diagram), called to improve with time:

1 - a jet could become pointless since the MIT prop type has just been proven safe,

2 - brands should offer a welll designed MIT prop for 2024,

3 - @VeFoil , @RC_guy, @Bufadore, @mkefoil, @phillhydrofoilismyli, @Mantafoils Transport Canada will have to review their copy - as an open prop blade can be safe at 4000 rpm although less efficient than a classic “Wageningen style” propeller ![]()

(*) costly because more Wh for same range, so bigger Wh battery (20-30% ?) + bigger front wing recommended, ex Takuma delivers the jet option with a 1750cm2 front wing + reinforced mast and plate, instead of a 1500cm2 and standard mast for the prop option.

'https://takuma.com/en/accueil/358-1330-efoil-carver.html#/72-battery-20a/172-propulsion-jet

a new reinforced mast and a top plate design.

**The Jet propulsion is delivered with the Kujira Helium 1750 wing**

I think it is worth it to go on with different shapes of the sharrow.because @HamburgHarbourFoiler showed that it is near by his best perfoming props at the moment. If it get very close in the next step or even equal it would bring more safety on the other side.

A first commercial toroidal prop at 239usd. Performance should be better than a jet and safe without duct as demonstrated by the merciless “courgette test”.

This propeller (…) was tested in a lab environment with Lift Efoils under variable conditions. Better performance of up to 25% compared with the Lift stock Aluminum prop may be achieved at cruise speeds of up to 17 MPH. You should be able to increase your riding time

(…)

If you ride a board other than a Fliteboard or Lift, please let us know and we will adapt this prop to your board for no additional cost.

This 25% improvement smells like creative marketing to me. I’d rather see the power curve at speed and not thrust per amp.