The reason is more that you lift out of the water at higher speed with a large wing. Drag is higher but efoiling gives you the pleasure of having enough power accessible if you want it. My first xxl wing had to be pointed downwards to not fly out of the water at higher speed😄

Now i get it, thanks.

Keep thinking about a foil wing like an rc plane wing which is still valid but in foiling too much lift can also be an issue as you explained, versus in rc plane flying the sky and your eyesight is the limit ![]()

Makes sense that a bigger wing could produce to much lift and lift you completely out of the water or has to held down by leaning harder on the nose of the board. I guess the size L will be the sweetspot then. Dont want to break a rib on my first go because it got way to fast ![]() I can always go with a smaller wing later on.

I can always go with a smaller wing later on.

What motor VESC combo are you running? Does a 200A VESC really need to be watercooled or will a passively cooled module be enought with a 6516X Style motor?

Have a look at my builds, passive is possible and works but adds some weitgh and is more difficult to build. Some people also put the ESC at the top of the mast like Flightboard and cool it passively through the mast plate and alu mast.

Thank you will do. The placement on the mast sounds promising since i could fab up a plug and play connector into the mast too.

Lots of us have used a Fliteboard as a base and then built a VESC on mast - cooling drive unit.

Can’t recall who did the first one but I owe him a beer!! ![]()

This is an example

This is another one

That looks awesome and really compact but this way the forward/backward adjustment Rails of the mast and board connection is lost. I imagine with my DIY board attempt that could be an issue where i lock myself into a wrong non adjustable position and it could make it unusable or very hard to fly. I cant seem to find a good source about Center of Gravity of a whole board and how far back or forward the connection of the mast and board should be. Maybe a watercooled VESC like the normal 75200 could be better for my first attempt? But the newer non watercooled flipsky 75200 pro V2 has more sensors and is quite a bit cheaper. Still no idea what would be the best choice. Watercooling itself could also uproot some issues like debris in the intake, needs a compact reliable pump, more power consumption etc. I could also try to cool the 75200 V2 passively by making a watertight heatsink plate (Aluminum) that sticks out of the bottom of the board where the VESC mounts to. Lots of ideas at the moment haha

I did watercooling on first build. No need for pump - keep it simple.

Intentionally bringing water into the area where battery and/or electronics are present is NOT something I would do again. No disasters but lot of little leaks requiring constant maintenance. PIA!!

If you want to build board just model it after one of the better ones here or measure up a Fliteboard or Lift of the appropriate volume. They have worked out all the dimensions for mastbase placement. IMO the rider adapts their foot placement for each board so the need for adjustable track is debatable.

My two cents for what that worth😉

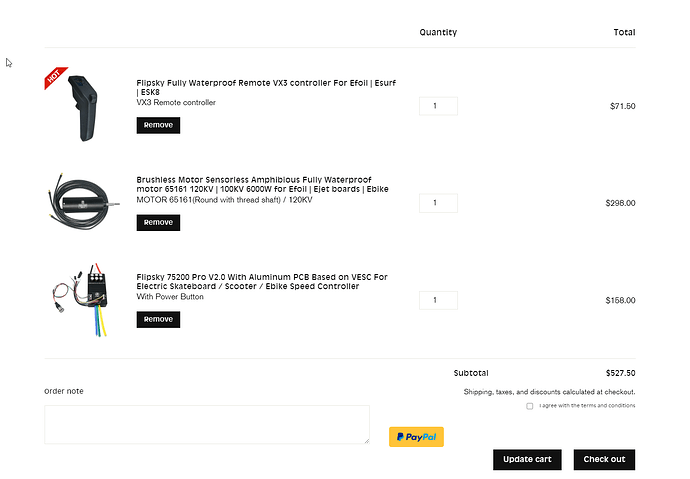

Im looking at the Lift an Flite boards construction as we speak and i think i will let my build be inspired by the Fliteboard Pro with EDIT: 67L size since im only around 75kg. I really like the idea of having a completely sealed battery compartment and the esc placed on the mast, as you mentioned no PIA with waterleaks or having water and battery mixed in the same compartment. I think ill hit the trigger on the Flipsky 65161 and the 75200 pro V2. Still not sure about the Flipsky VX3 since i read alot of mixed stuff about how its actually not fully waterproof. I know im probably focused really hard on flipsky right now but if it gets me into the sport and is affordable… Dont have the money for an easyfoil kit or flying rodeo kit. I guess ill let my creativity flow and my gut says 75200 V2 will be fine ![]()

Maytech remotes seem to performing even worse as far as i have seen in reviews.

Felix Remote would probably be golden but it blows my budget.

Ill probably end up buying the VX3, test it. Rip it apart right away and make my own waterproof enclosure for it

I have two VX3 and have never had a problem with either (fresh water use) I just bought a third to have a spare.

Have you seen this?

My order is already out. But its basically this kit without the prop. Ill go for the Fliteprop.

Should have gone for the kit to have a spare prop but damn, placed it already ![]()

The prop that comes with the kit is too big anyways and suitable props do not fit the splined shaft, good you ordered the shaft with M8 thread.

I’ll second @Foilguy and say I’ve not had any issues with my VX3 remote so far. One thing to note about it (and the Maytech remote) is that if you use it in salt water it should spend some time submerged in a container of fresh water afterwards to get it fully rinsed of salt.

Another popular remote option is the Bremote, which is sort of a diy kit solution developed by forum member ludwig_bre. The kits are available here: LR-BREmote - DIY KIT (electronics only) - openfoil.com

The “included” 7.5 inch aluminum prop is useless as is. I cut one down and it works OK but Flite prop is way better. The Flite prop is well made so not likely need a spare anyway. If you crash hard enough to damage the prop you have a LOT of problems😉

I’m all for redundancy though. I built an exact replica of my first Fliteboard based rig. ![]()

Hey, I’m in the same boat as you. About to design my own board in CAD and still unsure about whats the easiest way to achieve passive cooling with an adapter plate. Having the ESC fixed on the mast in a 3d printed box sounds like a great solution, but I would like to avoid drilling extra holes into the GONG top plate.

Since we are not using Fliteboard boards, it should be pretty simple to design an adapter plate that only uses the original holes. Are you also following that route?

Hello!

For now im currently in the design phase of my battery pack to make that work out like i want it to.

The plan is definitely to passively cool the VESC over the gong mast and baseplate itself.

I was also brainstorming and thinking about the positions of the wire connections like you. One way we could achive this is to slightly raise the VESC in the enclosure to be able to run the wires straight down. To still achieve good cooling the whole waterproof VESC box/adapter plate AIO, which sits ontop of the mast could be flooded with a thermally conductive fluid such as non conductive EDM fluid (Used in EDM Machines). Or for a more accessible option with another non conductive fluid. Ive seen some people build Custom PC’S in tanks full of mineral oil.

The submerged option in dielectric fluid would give many challenges of fully waterproofing the VESC and all connections itself but will produce a really good thermal solution. Although it will be messy in testing id imagine.

The simplest option will be milling relief Channels into the baseplate where the VESC sits to run the cables straight down, but it will sacrifice much of the needed cooling surface and strengh of the plate.

From the other foilers experience, the cooling seems to be really sufficient. I guess one hole in the mast plate is unavoidable :). I will start drawing my base board first and then later worry about it

Have you seen this build? It was reliefed on the underside of the custom plate to make space for the cables. https://foil.zone/t/frankenstein-build-fliteboard-gong-v2-mast-flipsky-75200-vesc-and-in-my-case-a-tritonfoils-x1-monofoil/19516/40

I have a Fliteboard adapter plate build. I don’t have my own build thread (yet), but I bookmarked a few of the other adapter plate builds:

UK Efoil build V2 (not really adapter plate, but similar)

There are also a few builds that have used metal boxes filled with corrosionX. This is one example:

Yes a very nice build indeed. Why was is necessary to drill 4 new holes into the mast plate? I think the others did not need to do that, right? Since we are not bound to an existing Fliteboard cutout, I guess an adjusted adapter plate where the original mast plate screws fit should be no problem. All the outer form could be simplified, since I’m a little worried about glassing this shape. Maybe a simple rectangular plate with multiple holes is enough?