FlyColor 150A works great, two ESC FATJAY 120A and one Toro TS150 burned out.

moving forward on the cable choice. 3x2.5mm marine cable is given for 16A. Overall size is 11mm

that’s not much… isn’t it?

You can use an online calculator to see your losses. Seem ok to me

2,5mm2 / phase isn’t enough for me , check on calculator , even if it depends on the overall length and it will be cool by air /water , and it is working on pulse current , I would choose a bit higher

What are your friend feedbacks ? Have you been able to check their setup ?

Not sure whether it is still needed but link was posted a coupled of days later on another post… ensymlefax aka superlefax on this forum

Hello,

this is my approach of a lightweight and cheap wingfoil drive assist:

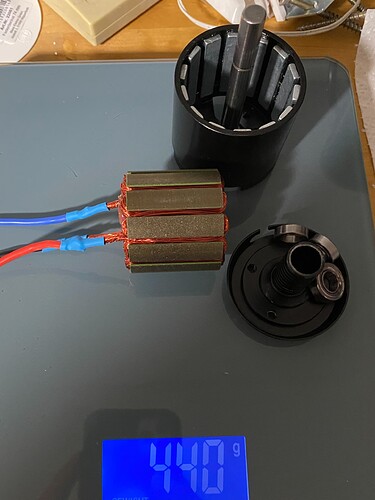

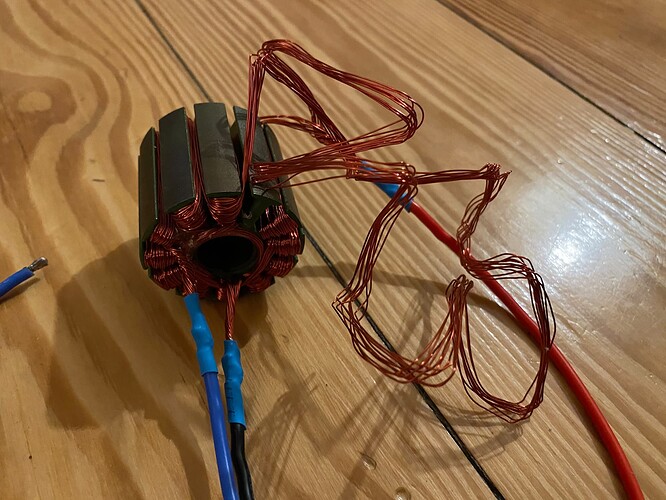

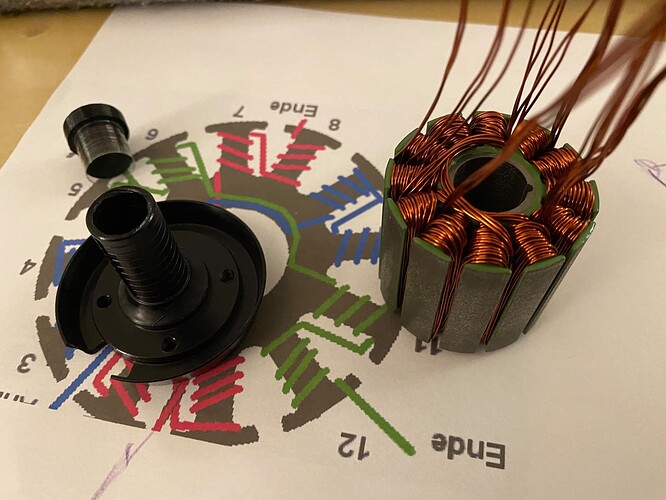

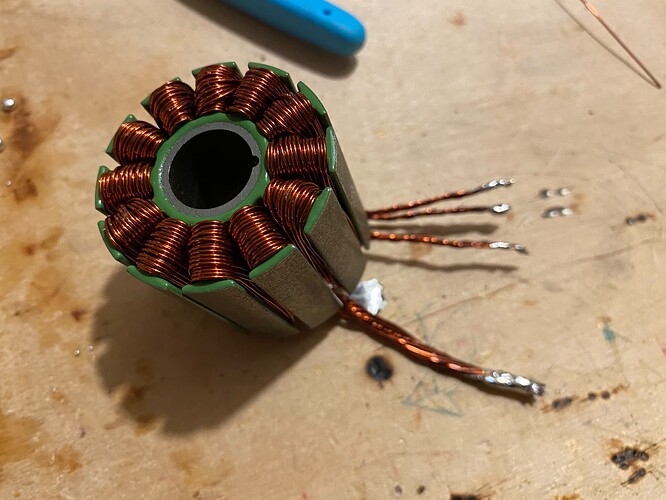

- small 5065 330kv motor, rewound to 8 turns in Y-configuration, resoldering the original winding from delta to Y may also work (7 turns if I counted correctly)

- 3d printed „clip-on“ mast mount and folding prop

- Flycolor 90A ESC

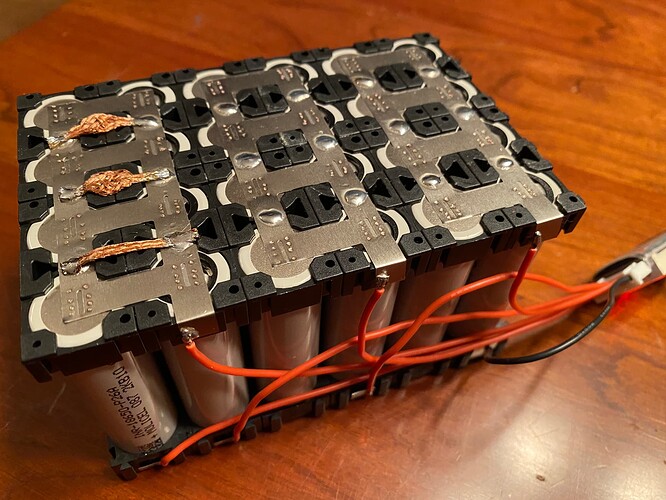

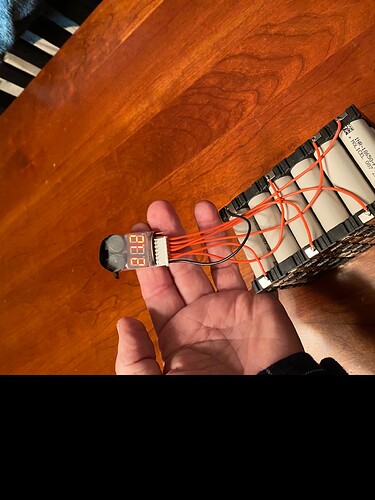

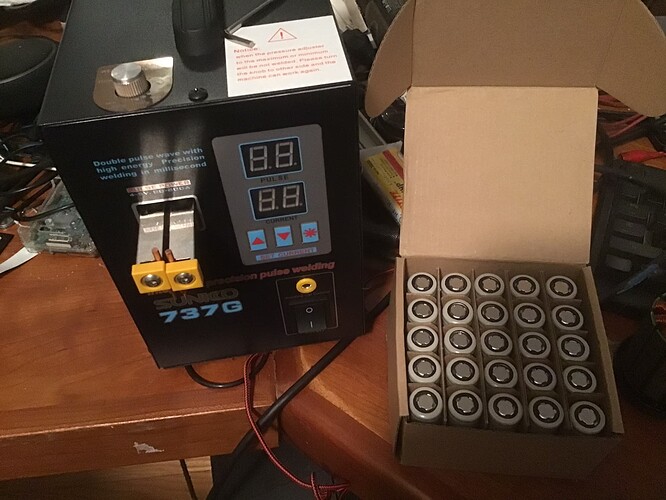

- 6s2p Samsung 40T battery pack

- cheap waterproof remote and electronic box (cannot really recommend the box as it was hard to make it really waterproof)

—> ~200€ for parts and only 2kg overall weight

Tested only few times yet but power seems to be perfect for wingfoiling. I measured 12-13kg static thrust @1000W. It makes getting up on the foil much easier and effortless in light wind (does not get me out of the water without wing, though). It is definitely not made for continuous use, but a few seconds are enough in this usage. Might be possible to make it even more lightweight with smaller battery and lighter cable/housing.

Merry Christmas to everyone!

200€ is a good value for money !

Would you have kept images of these steps ?

Here are a few images, the last two show the new winding. I did not take any pictures of the steps in between…

Thanks. Would you recall the calculus that lead you to these conclusions ? Links that inspired you ?

I would say it was a bit trial and error. I first tested the original winding (330kv) in a water tub with a small prop (120mm) but that did not seem to work at all (too much current, motor getting out of sync, …). Changing from delta to Y should lower kv by a factor of sqrt(3) = 1.73 (Chosing the right BLDC motor and battery setup for an electric skateboard | Benjamin's robotics), resulting in about 190kv in this case. I decided to try one more turn to make kv even lower and tried different props (increasing diameter). The props shown are about 143mm and work well (at least in my limited testing) but can certainly be optimized. I used this website for the winding scheme, but it seems to be down at the moment: powerditto 12N verteilt bewickeln

Nice build!

I like the rewinding of the motor to lower the kV.

Looks similar to the Foil Drive kit

They have quite a good instructional video as well, worth a watch for some extra ideas.

I quite like the 3M Dual Lock for attaching the box to the board.

Has anyone seen the battery up close on a foil drive, is it 6s4p with 18650 cells?

Any suggestions on a thin and light waterproof membrane for the battery, such as a type of plastic sheet which is flexible and glues easily?

Looks like it, if you draw a circle in the upper rightmost cell, seems you need 4 to cover the width.

I made mine 6S4P with Molicel P26A (2600mAh 35A) 18650 cells. No BMS. Wired for balance charger. Foam wrap and then shrink wrapped.

I’d like to find something more waterproof than shrink wrap for covering the battery, such as an adhesive flexible film, or plastic that sticks well with glue. Salt water into the battery is a  in the making.

in the making.

Inspired by this thread, I took a stab at building my own assist. I posted a build thread on that topic

But I am having some propulsion issues that I hope I can resolve.

There are some more tips on preparing an outrunner for use in water in this thread…

One suggestion was to use liquid electrical tape on the wiring solder joins at the motor, or plenty of silicone inside heatshrink.

Coat the stator thinly with epoxy so that it can be cooled by water. Fill the gaps between magnets on the bell with epoxy (with microballons) to protect them from rusting and reduce drag.

So here is another update. I’ve re-wired my cables back on the motor. Hopefully the connection remains good. I’ve been using the motor 50/50 these days, getting better at downwinding. It’s great for light wind sessions when you want 100% pop up guaranteed. Hoping to see more DIY FauxDrivers on the water soon. The motor drag is definitely noticeable when foiling at speed on touch downs. I run my motor as high up the mast as possible on a 32” mast. My battery box sits nicely on the tail behind my back foot. This device has been a total game changer for me this summer.